- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1400kg

-

Size:

-

822*2997*1321

-

Power:

-

1.73

-

Weight (KG):

-

1500 kg

-

Product name:

-

Sludge Dewatering Machine

-

Other name:

-

Multi disc screw press sludge dehydrator

-

Application:

-

Solid-liquid Separation

-

Brand:

-

IEPP

-

Control:

-

Button/PLC

-

Packing:

-

Seaworthy Package

-

Processing:

-

Sludge Dewatering

-

MOQ:

-

1 Set

-

Advantage:

-

24/7 Hours Automatic Running

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

IEPP

-

Material:

-

Plywood, 304 stainless steel

-

Weight:

-

1400kg

-

Size:

-

822*2997*1321

-

Power:

-

1.73

-

Weight (KG):

-

1500 kg

-

Product name:

-

Sludge Dewatering Machine

-

Other name:

-

Multi disc screw press sludge dehydrator

-

Application:

-

Solid-liquid Separation

-

Brand:

-

IEPP

-

Control:

-

Button/PLC

-

Packing:

-

Seaworthy Package

-

Processing:

-

Sludge Dewatering

-

MOQ:

-

1 Set

-

Advantage:

-

24/7 Hours Automatic Running

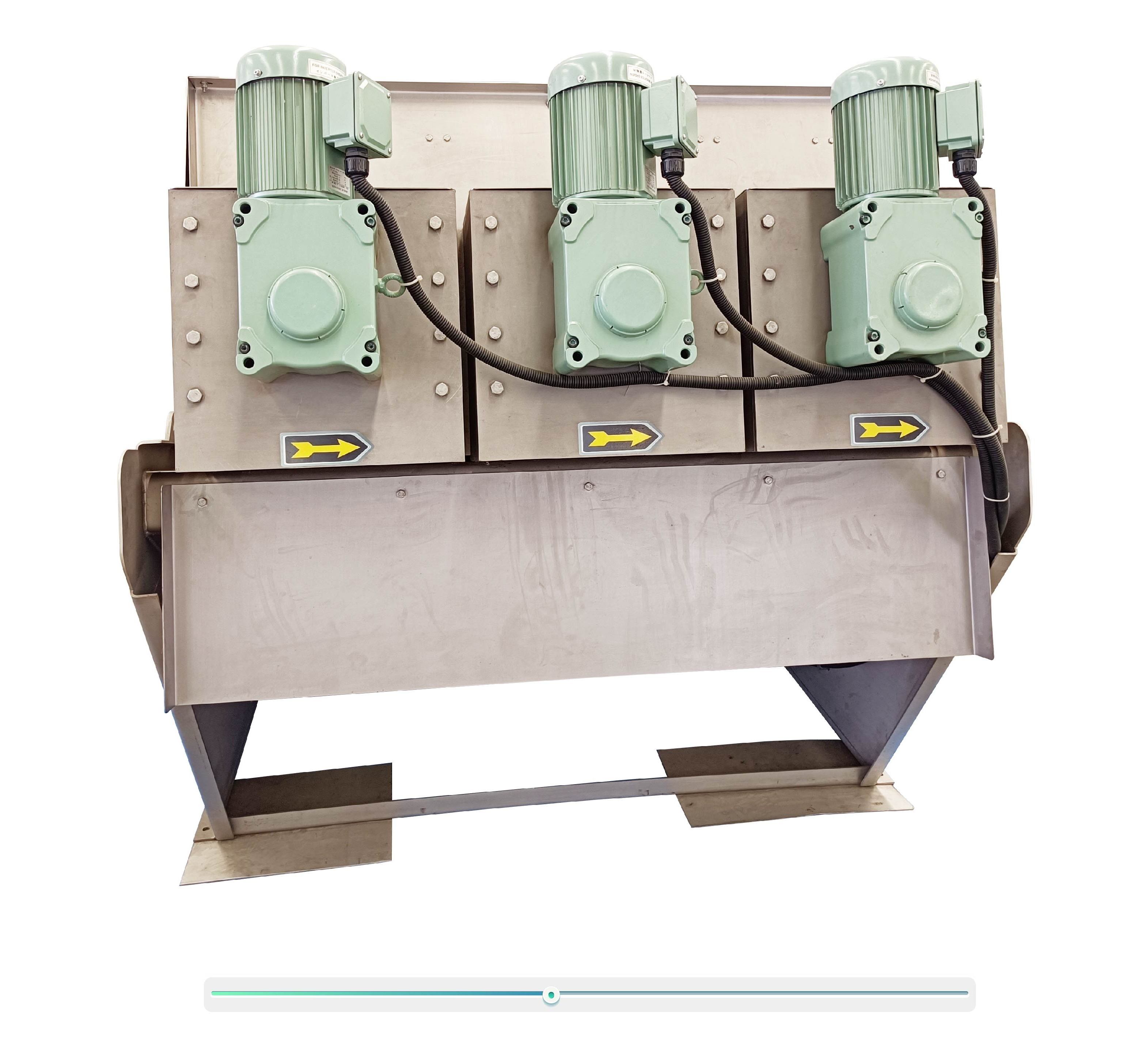

IEPP factory manufacturer supplier sludge dewatering machine multi-dish screw press dehydrator mud dryer for sewage treatment

The volute dehydrator dewatering drum consists of rings with a variable-pitch aguer running through the center. Every second ring is fixed to the barrel assembly and separated by spacers. Intermediary rings are free to move. The internal diameter of the fixed rings is larger than the diameter of the auger. The intermediarey rings have an ID slightly less than the auger and hence are moved in an orbital motion as the auger turns. The movement of the intermediary rings constantly cleans the barrel assembly allowing free drainage of water. This arrangement allows for an extremely low power draw.

Dilute sludge is introduced into a flocculator tank at the rear of the unit and mixed with a polymer solution to produce flocs. The flocs then overflow into the barrel and free water is drained as they are transported along the auger. Final compression of the sludge cake at the end of the auger is enhanced by decreasing both the pitch of the auger and the spacing between the fixed and intermediary rings.

|

YPDL-201

|

0.55

|

2997

|

822

|

1321

|

10-20

|

SS304

|

|

YPDL-202

|

0.73

|

2997

|

1128

|

1321

|

20-40

|

SS304

|

|

YPDL-251

|

0.7

|

3193

|

964

|

1317

|

35-45

|

SS304

|

|

YPDL-252

|

0.95

|

3193

|

1112

|

1317

|

70-90

|

SS304

|

|

YPDL-301

|

1.5

|

3171

|

980

|

1645

|

30-60

|

SS304

|

|

YPDL-302

|

2.25

|

3364

|

1340

|

1645

|

60-120

|

SS304

|

|

YPDL-303

|

3

|

3535

|

1538

|

1645

|

90-180

|

SS304

|

|

YPDL-351

|

1.5

|

3760

|

997

|

1700

|

50-100

|

SS304

|

|

YPDL-352

|

2.25

|

3890

|

1421

|

1700

|

100-200

|

SS304

|

|

YPDL-401

|

1.73

|

4300

|

1300

|

1880

|

40-80

|

SS304

|

|

YPDL-402

|

2.83

|

4600

|

1600

|

1900

|

80-160

|

SS304

|

|

YPDL-403

|

4.13

|

4750

|

2000

|

1900

|

120-240

|

SS304

|

|

YPDL-404

|

5.23

|

5105

|

2880

|

2390

|

160-320

|

SS304

|

1.Q: Can the multi disc screw sludge dehydrator be placed outside?

A: Yes, but the protective performance of the corresponding

electric cabinet and motor should be improved. For examplethe

motor needs to add rainproof cover motor protection P55IP65 etc.

2.Q: What kind of sludge is the multi disc screw sludge dehydrator

suitable for?

A: The dehydrator is a multi disc solid-liquid separator which is

suitable for most occasions requiring solid-liquid separation.

The obvious advantage of the equipment is that it can process oily

sludge, and the sludge concentration range from 5000mg/L to

50000mg/L.

3.Q: Does multi disc screw sludge dehydrator need to add medicine?

A: Yes, it is necessary to add flocculants to sludge to form alum flower with certain particle size and strength to enter the main body of the dehydrator for dewatering.

4.Q: Does the multi disc screw sludge dehydrator have the self-cleaning function to avoid blockage without backwash pump?

A: Yes. In fact, during the operation, the swimming rings are in constant motion and have the function of self-cleaning filter joint to prevent clogging.

5.Q: What are the advantages of multi disc screw sludge dehydrator compared with traditional filter press?

A: 1. Good at handling oily sludge. 2. Compact design, saving space.

3. Simple operation and

maintenance. 4. Saving electricity &water. 5. Low noise and vibration.

Hot Searches