- Product Details

- {{item.text}}

Quick Details

-

Rated Power:

-

6KW

-

Engraving Speed:

-

150mm/s

-

Main Axle Rotational Speed:

-

36000rpm

-

Feeding Height:

-

165mm

-

Milling Cutter Diameter:

-

3.4.6mm

-

Dimensions:

-

2790*2120*2250

-

Weight (KG):

-

4600

-

Spindle power:

-

6kw

-

Processing Material:

-

Metal

-

Product name:

-

ND1200 CNC machine

-

After-sales Service Provided:

-

Engineers

-

CNC or Not:

-

CNC

-

Working area:

-

1200*800*165mm

-

Keyword:

-

Metal Making Machine

-

Function:

-

Die Engraving

-

Marking Accuracy:

-

0.005-0.008

-

Marking Speed:

-

150mm/s

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ND

-

Machine Type:

-

CNC machine

-

Rated Power:

-

6KW

-

Engraving Speed:

-

150mm/s

-

Main Axle Rotational Speed:

-

36000rpm

-

Feeding Height:

-

165mm

-

Milling Cutter Diameter:

-

3.4.6mm

-

Dimensions:

-

2790*2120*2250

-

Weight (KG):

-

4600

-

Spindle power:

-

6kw

-

Processing Material:

-

Metal

-

Product name:

-

ND1200 CNC machine

-

After-sales Service Provided:

-

Engineers

-

CNC or Not:

-

CNC

-

Working area:

-

1200*800*165mm

-

Keyword:

-

Metal Making Machine

-

Function:

-

Die Engraving

-

Marking Accuracy:

-

0.005-0.008

-

Marking Speed:

-

150mm/s

ND1200 series CNC machine

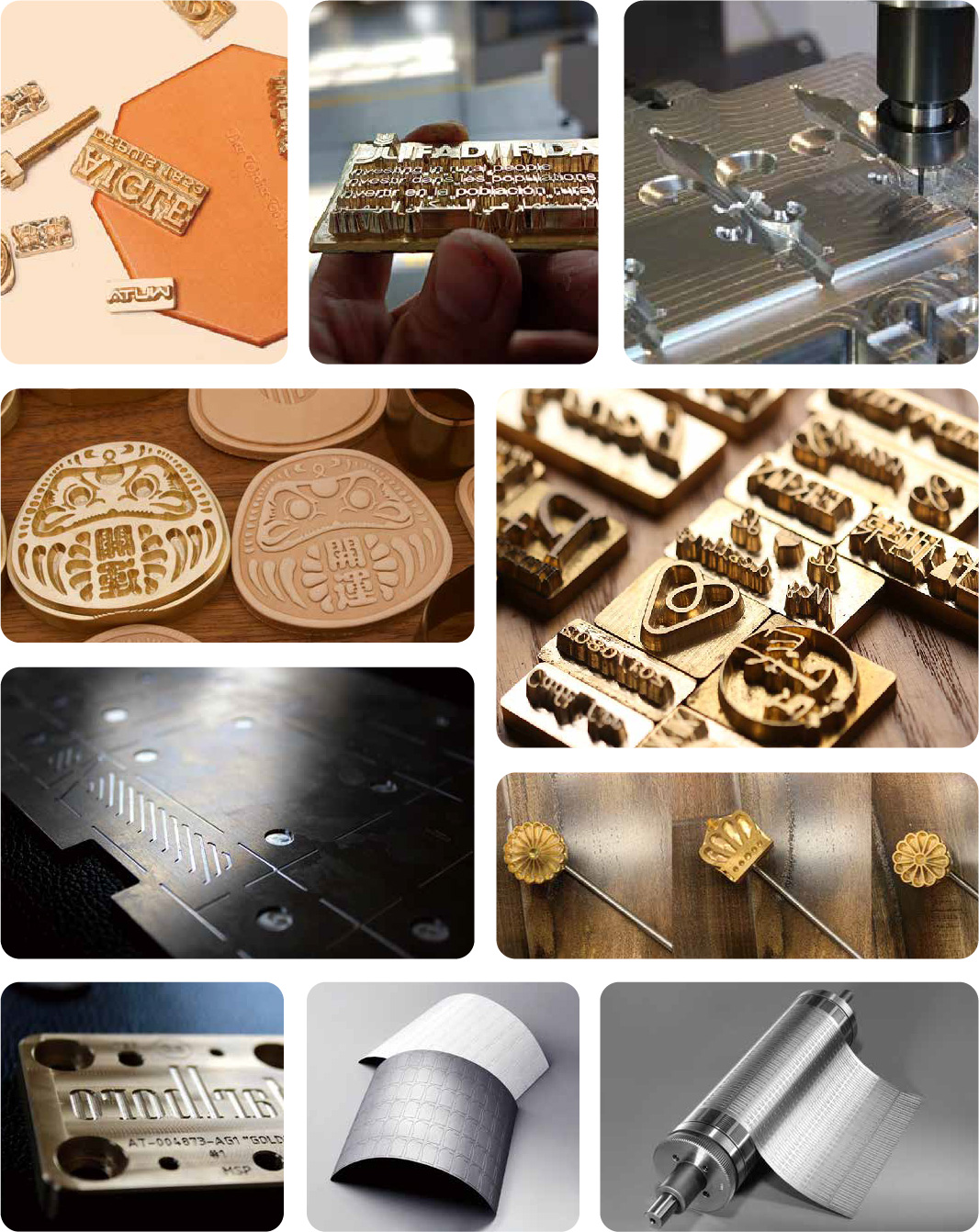

The main application direction of CNC equipment in the printing and hot stamping packaging industry is the processing of hot stamping plates.

The materials of hot stamping plate are copper/brass plate, zinc plate, magnesium plate and aluminum plate. The common processes in the market are embossing and foil stamping.

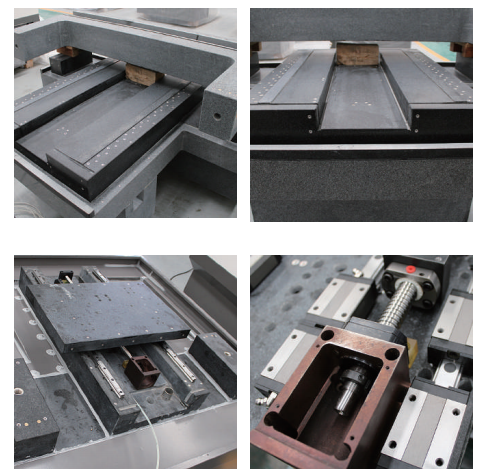

| Project | ND1200 series |

|

Positioning accuracy(

X/Y/Z axis)

|

0.008mm |

| Repeated positioning accuracy( X/Y/Z axis) | 0.005mm |

| Straightness accuracy( X/Y/Z axis) | 0.005mm |

| Working distance( X/Y/Z axis) | 1200x800x150mm |

| Power | 6KW |

| Spindle diameter |

100mm |

|

Rapid moving speed(

X/Y/Z axis)

|

15.0m/min |

| Max grinding speed( X/Y/Z axis) | 6.0m/min |

| Square dimension accuracy | 0.01mm |

| XY plane roundness | 0.015mm |

| Refrigeration flflow | ≥1.5mm |

| Refrigeration pressure | 2.5-4.0 kgf/cm2 |

| Working voltage | 380/50V/Hz |

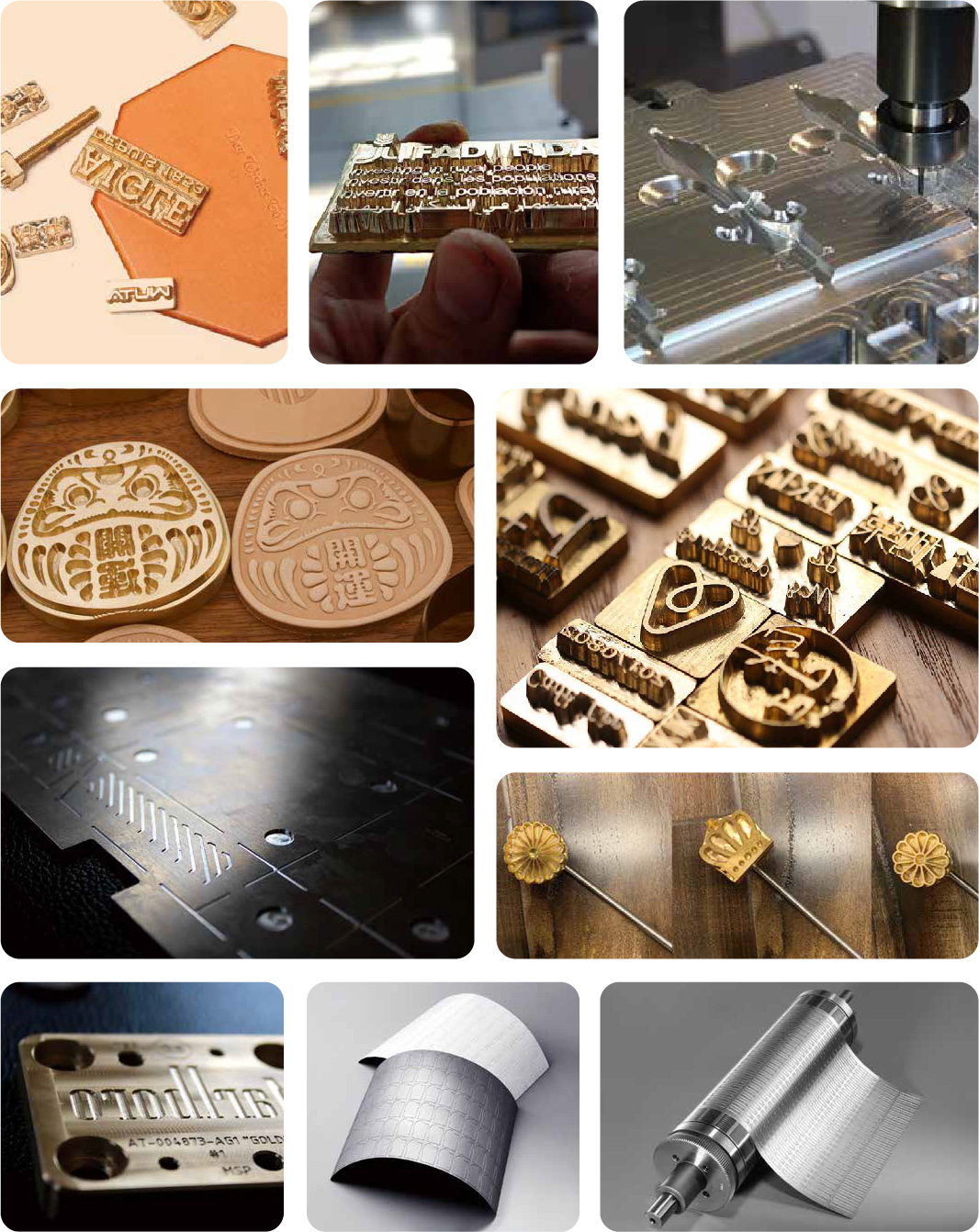

Granite Based

Servo System

All axis systems of the equipment adopt Panasonic servo motor to ensure high precision in the driving process.

According to different requirements and different applications, the most suitable machine configuration can be selected.

Tools changer system: We can choose the number and method of tool change.

6 linear tool change/16 disc tool change.

Table Type: Vacuum table/T-slot table.

Probe&Linear gauge system.

CCD carema system.