- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

20-70 bags/min

-

Weight (KG):

-

700

-

Voltage:

-

380V/220V/50/60Hz

-

Place of Origin:

-

China

-

Product name:

-

Automatic Roary Premade Bag Packing Machine For Granule

-

Bag type:

-

Premade bag (flat bag, stand-up bag, zipper bag, M bag)

-

After Warranty Service:

-

On-site Technical Support

-

Automaticity:

-

Fully Auto

Quick Details

-

Function:

-

FILLING, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Production Capacity:

-

20-70 bags/min

-

Weight (KG):

-

700

-

Voltage:

-

380V/220V/50/60Hz

-

Place of Origin:

-

China

-

Product name:

-

Automatic Roary Premade Bag Packing Machine For Granule

-

Bag type:

-

Premade bag (flat bag, stand-up bag, zipper bag, M bag)

-

After Warranty Service:

-

On-site Technical Support

-

Automaticity:

-

Fully Auto

|

Model

|

ZD100

|

ZD200

|

ZD320

|

||

|

Speed

|

70 bags/min

|

60 bags/min

|

50 bags/min

|

||

|

Pouch size

|

L≤360mm

W:80-210mm |

L≤400mm

W:130-250mm |

L≤400mm

W:150-300mm |

||

|

Working position

|

10

|

8

|

8

|

||

|

Pouch pattern

|

Premade bag (flat bag, stand-up bag, zipper bag, M bag)

|

|

|

||

|

Gas source

|

6Kg/cm²,0.4 m³/min

|

|

|

||

|

Pouch material

|

Single layer PE, PE composite film, paper film and various other composite films

|

|

|

||

|

Weight

|

700kg

|

700kg

|

720kg

|

||

|

Voltage

|

380V/7.0Kw

|

|

|

||

|

Dimensions

|

1950×1400×1520mm

|

1950×1400×1520mm

|

2100×1500×1520mm

|

||

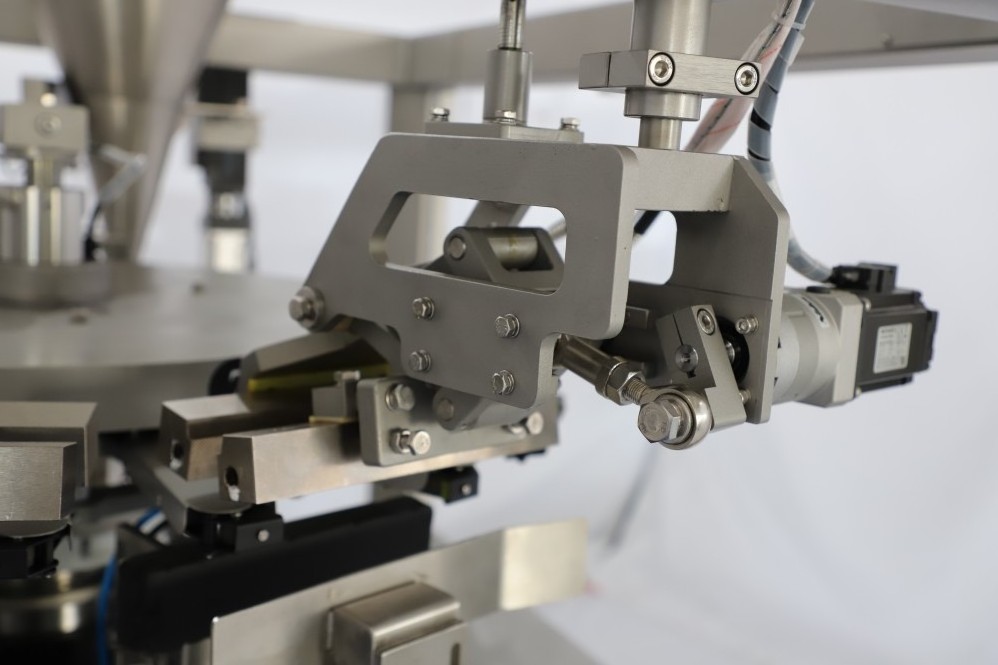

Premade Pouch Packing Machine

:

According to different materials, Rotary packing machine can be divided into three different configurations and applications. They are applied to granular, powder and liquid materials respectively. When rotary packing machine is equipped with multihead weigher mechanism. This equipment is specialized in granule, such as grain, chips, cookies, puffed food, peanut, chile, dry fruits, frozen fruits, pasta, beans, chia seeds, gum, refined gourmet powder, seed, chemistry condiment, granulated sugar, candy, chicken essence, melon seeds, nuts,fertilizer, etc. This premade bag packing machine is suitable for automatic packaging of small packaging bags, medium bags, small metering strip bags of various powder and granular products.

1. Automatic rotary packing machine adopt precision indexing device and PLC to control each action and working station to make sure the machine operates easily and does accurately.

2. The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch..

3. Automatic checking system can check bag situation, filling and sealing situation.

The system shows 1.no bag feeding, no filling and no sealing. 2.no bag opening/opening error, no filling and no sealing

4. The product and pouch contact parts are adopted stainless steel and other advanced material to guarantee the hygiene of products.

Additional location function:

According to the bag specifications and form, combined with the production material, corresponding to choose the followingadditional features used in the machine:

1. 5 stations tong material (cylinder tong material, suitable for use of liquidity is not high and twice raw material adding)

2. 6 stations tong (cantilever barrels of material)

3. The exhaust (applicable to eliminate gas needed materials)

4. Under vibration (also called bag vibrate, applicable to material block or large material)

5. Level bags(applicable to zipper bags and soft bag)

6. Open the zipper bag (applicable to zipper bag)

7. Close zipper (applicable to zipperbag)

8. The open bag (applicable to zipper bag and not easy to open the bag)

9. Hopper vibration (applicable to low liquiditymaterial)

10. Sweep dust and dust (applicable to powder)

Q1: Are you a factory or a trading company?

A1:We are the factory with manufacturing and self-supporting import and export rights for more than 25 years.

Q2: How to choose suitable packaging machine?

A2:Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How about the payment way?

A3:Payment can be T/T, L/C etc. we can provide FOB, CNF, CIF term by sea.

Q4: How to ensure the quality of the machine?

A4:We usually delivery the machine after successful inspection in our factory. We have our own quality control department,before the delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q5: How to install the equipment?

A5:We will provide manuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

Hot Searches