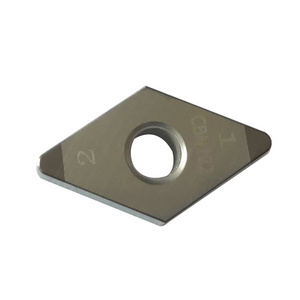

Standard:

S02020, S05020

Length x degree:

0.2mm x 20 degree, 0.5mm x 20 degree

Application:

0.2mm x 20 degree is for finish cutting or semi-finish cutting

0.5mm x 20 degree is for rough cutting.PCD PCBN Inserts Tool Holder

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RZ

-

OEM:

-

Accpeted

-

Product name:

-

Pink Grinding Head

-

Shape:

-

customize

-

MOQ:

-

10pcs

-

Application:

-

Cutting

-

Keyword:

-

Abrasive tools

-

Advantage:

-

Higher Efficiency

-

Color:

-

black

Quick Details

-

Usage:

-

External Turning Tool

-

Hardness:

-

SUPER HARD

-

Coating:

-

PCD

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RZ

-

OEM:

-

Accpeted

-

Product name:

-

Pink Grinding Head

-

Shape:

-

customize

-

MOQ:

-

10pcs

-

Application:

-

Cutting

-

Keyword:

-

Abrasive tools

-

Advantage:

-

Higher Efficiency

-

Color:

-

black

Related Products

Products Description

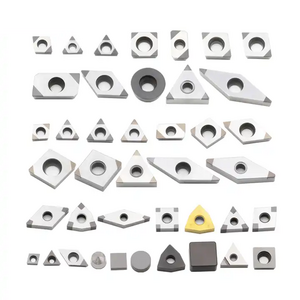

PCD PCBN Carbide Turning Inserts CNC Tool Holder with Inserts

PCD tools are composed of diamond particles that are infused into a metallic binder to create one of the most abrasion-resistant and durable materials in the metal cutting industry. You can rest assured that your PCD tool will be built to last and will cut your products with ease.

PCD tools are also offered in a variety of forms and quality grades.Our company - Zhengzhou Ruizuan Diamond Tool Co., Ltd.developed CBN and Diamond Products with different grades for different application.

|

Grades

|

Application

|

Hardness HV

(Mpa)

|

Bending strength

(Mpa)

|

|

Z905

|

Fit for low speed heavy load rough machining.

●High pyroconductivity, definite impact resistance. ●Fit for rough machining of high-hardness alloy cast iron, gray cast iron, nodular cast iron and other materials. |

3000--3200

|

1100--1300

|

|

RZ907

|

Consider abrasion resistance and tipping resistance, high-speed continuous cutting.

●Fit for rough machining and semi-finishing of high-hardness alloy cast iron, high nickel chromium, high ferrochrome and other materials. ●Fit for rough machining and semi-finishing of gray cast iron and nodular cast iron. |

3200--3400

|

1100--1300

|

|

RZ957

|

Excellent wear resistance and heat resistance, high-speed continuous cutting and milling.

●Fit for semi-finishing and finish machining of alloy cast iron, high nickel chromium, high ferrochrome and other materials. ●Fit for semi-finishing and finish machining of gray cast iron, nodular cast iron, and other materials. |

3300--3500

|

1100--1200

|

|

RZ900

|

Excellent wear resistance, tipping resistance and generality, low-speed interrupted cutting.

●Fit for rough machining of quenching workpieces, such as bearing steel, die steel, gauge steel, tool steel, high-speed steel and other materials. |

3000--3200

|

1100--1300

|

|

RZ950

|

Excellent wear resistance and heat resistance, high-speed continuous cutting and milling.

●Fit for semi-finishing and finish machining of quenching workpieces, such as bearing steel, die steel, gauge steel, tool steel, high-speed steel and other materials. |

3000--3200

|

1100--1200

|

Detailed Images

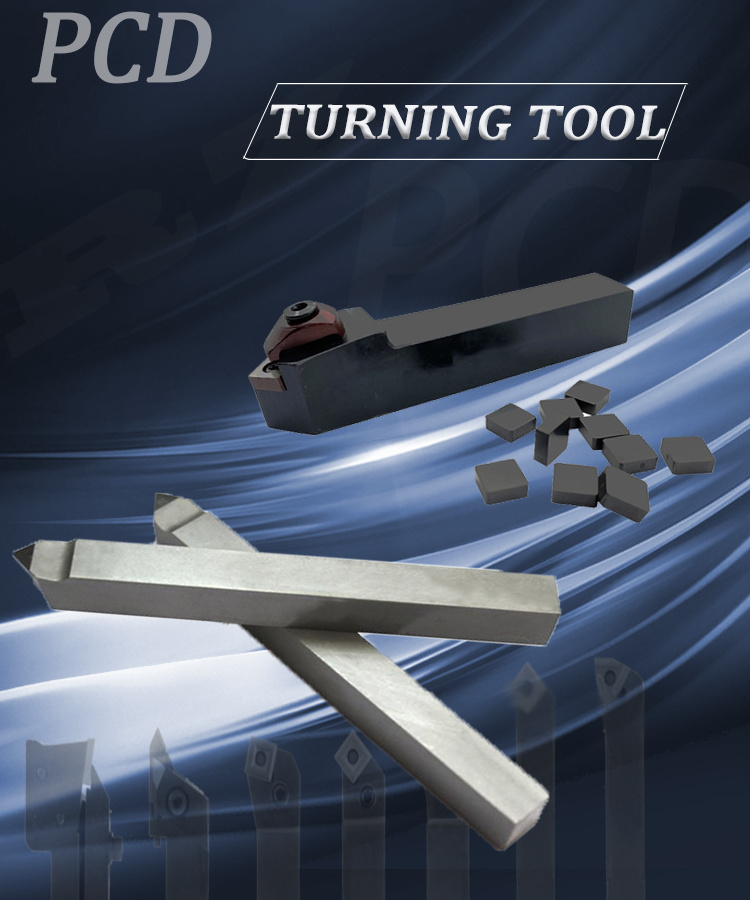

PCD detachable turning tool

PCD welding turning tool

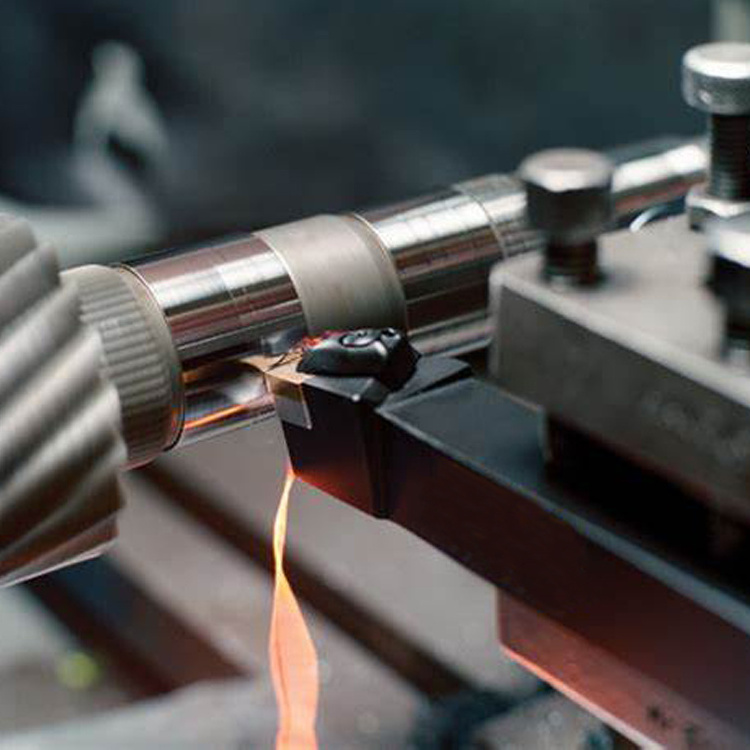

Metal lathe cutting tool PCD Turning Tool Not only can our turning tools be used for conventional lathes, turret lathes, automatic

lathes and custom machines, they can also be used for boring heads and milling machines. They are equally at home with both

external and internal machining.

Advantages

Advantages:

* Enables high speed machining while maintaining longer tool life.

* Provides consistent products, simplified quality control, and lower cost.

* Maximum stability.

* Maximum economy.

* Maximum feed/speed.

* Suitable for general and optimized final machining

Application

Cutting Materials

Cast Irons, Grey cast irons, Steel, hardened steels, High nickel chromium, high ferrochrome,bearing steel, die steel, gauge steel,tool steel, high-speed steel, HSS steel.PCD PCBN

Why Choose Us

Hot Searches