- Product Details

- {{item.text}}

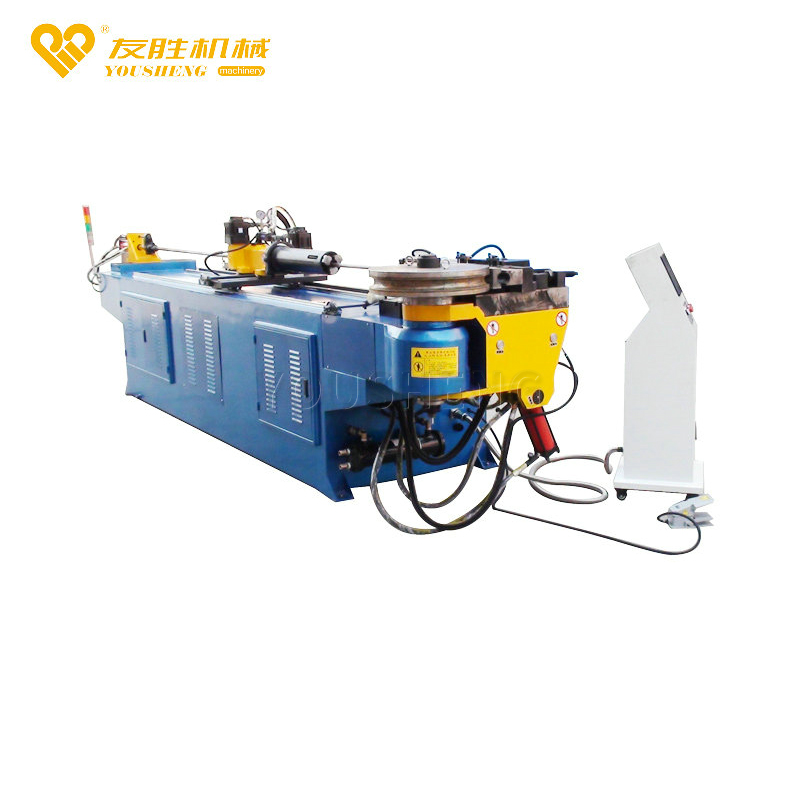

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

yousheng

-

Year:

-

New

-

Power (kW):

-

7.5

-

Weight (KG):

-

2000

-

Warranty:

-

1 Year

-

Color:

-

Blue

-

Motor power:

-

NC

-

Max Capacity for seel pipe:

-

25mmx2mm

-

Max bending angle:

-

0-190°

-

Max feeding length:

-

2200mm

-

Max rotating speed:

-

200°/sec

-

Product name:

-

pipe bending machine

Quick Details

-

Bending Radius (mm):

-

20 - 100

-

Max. Bending Angle (Deg):

-

190

-

Bending Precision (Deg):

-

±0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

yousheng

-

Year:

-

New

-

Power (kW):

-

7.5

-

Weight (KG):

-

2000

-

Warranty:

-

1 Year

-

Color:

-

Blue

-

Motor power:

-

NC

-

Max Capacity for seel pipe:

-

25mmx2mm

-

Max bending angle:

-

0-190°

-

Max feeding length:

-

2200mm

-

Max rotating speed:

-

200°/sec

-

Product name:

-

pipe bending machine

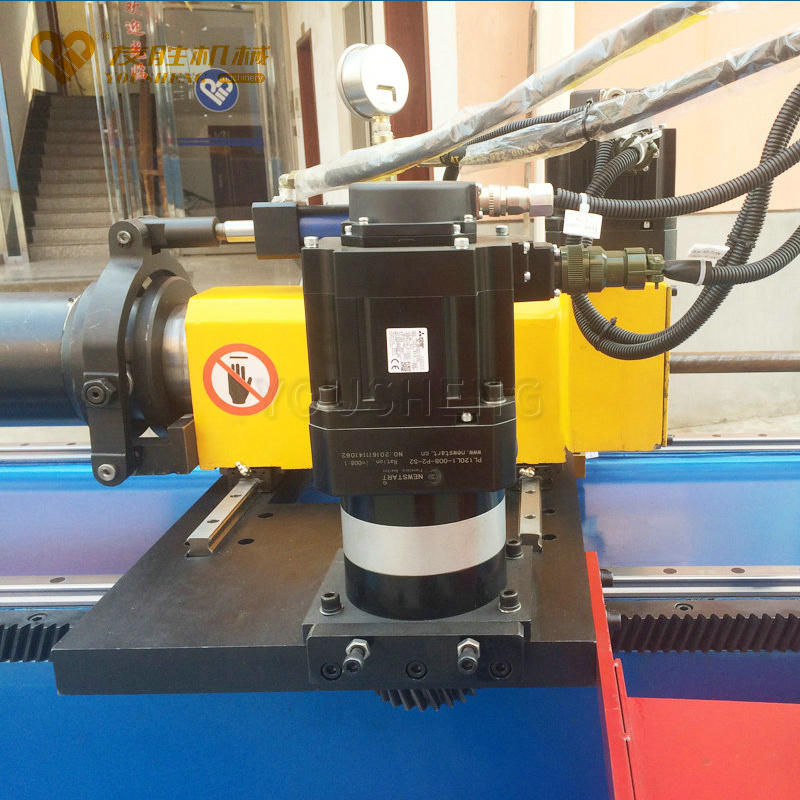

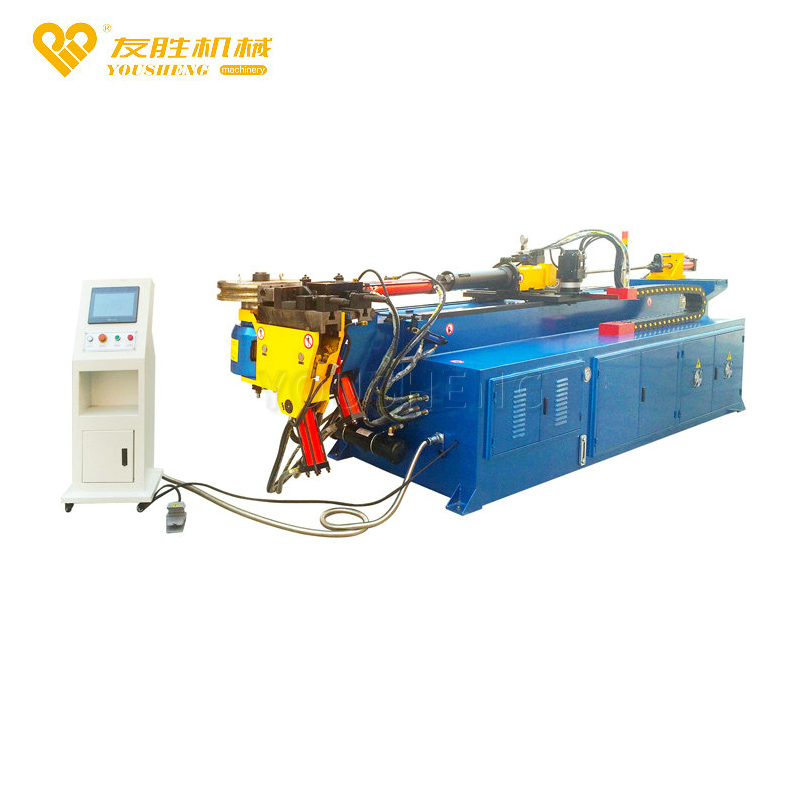

1. Electric control system: world-renowned controllers are applied. For example, servo drivers, servo motors, positioning modules produced by Mitsubishi, have strong performance and excellent stability.

2. All processing data is input through the touch screen and each elbow can set compensation value, speed and mould clearance according to different materials.

3. It can detect the error and fault automatically and display them on screen, so that the operator can eliminate the failures easily.

4. Materials can be delivered directly or wrapped according to requirements and XYZ coordinates can be switched to YBC processing values automatically.

5. Chinese and English on the touch screen can be switched and the products can also be ordered according to requirements if it is another language on the screen. (Optional)

6. Anticipated mandrel retraction unit. With high stability.

7.With air-cool system on electric cabinet, water cooling system on hydraulic system for stable operation of two (2) shifts per day (eight (8) hours per shift), seven (7) days per week. Heat ex-changer is provided for the electric control system for automatic heat dissipation. If required, NC air conditioner can be purchased to ensure service life of electric control system. (Optional)

8. Touch screen operation panel, you can input, store and display bending data and to control the machine bending.

9. Maximum bending program memory capacity 500 groups, each group can be programmed up to 30 bending.(expandable), industrial computer panel can memory one million groups.

10. The machine can be with automatic oil injection system to reduce friction of elbow and ensure quality of elbow. (Optional)

11. WINDOWS operating system is installed in industrial computer (Optional) to be mated with servo syste m.

12. The feed position of feed trolley, the interference position of safety device and digital module and interference position of guide mould can be fine adjusted manually and memorized automatically to eliminate the error of manual measurement and losses caused by machine collision.

13. The feed shaft will be detected automatically before action so that it can be prevented from colliding with the machine.

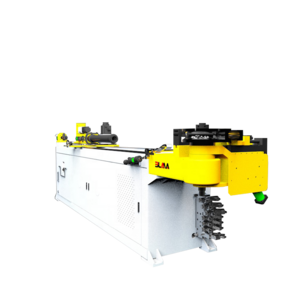

| Specification/Model | DW-25CNC | DW-38CNC | DW-50CNC | DW-63CNC | DW-75CNC | DW-89CNC |

| Max Capacity for seel pipe | φ25mmx2mm | φ38mmx2mm | φ50mmx2.5mm | φ63mmx3mm | φ75mmx3.5mm | φ89mmx4mm |

| Max capacity for stainless steel | φ20mmx1.5mm | φ30mmx2mm | φ42mmx2mm | φ50mmx2mm | φ63mmx3mm | φ75mmx4mm |

| Bending radius | R20-R100mm | R25-R180mm | R35-R250mm | R35-R250mm | R50-R350mm | R50-R350mm |

| Max bending angle | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° |

| Max feeding length | 2200mm | 2500mm | 2800mm | 3200mm | 3300mm | 4000mm |

| Max bending speed | 75°/sec | 70°/sec | 65°/sec | 60°/sec | 44°/sec | 40°/sec |

| Max rotating speed | 200°/sec | 200°/sec | 200°/sec | 160°/sec | 160°/sec | 160°/sec |

| Max feeding speed | 1000mm/sec | 1000mm/sec | 1000mm/sec | 800mm/sec | 800mm/sec | 800mm/sec |

1. Q: Are you trading company or manufecturer ?

A: We are manufecture.

2. Q: How long is your delivery time?

A: The standard model is 7-15 days, the customized model is 30-60days.

3. Q: How to choose the model of machines?

A: -Max. outside diameter

-Wall thickness range:

-Bending radius (CLR)(just for pipe bending machine):

-The pipe material:

-The drawings if possible(the best for recommend right model):

4. Q: Do you provide samples ?is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

5. Q: What is your term of payment ?

A:30% T/T in advance, the balance pay before shipment.

6. Q: How is shipping?

A: Shipping by sea, by air, by Express (DHL/UPS/FEDEX/EMS/TNT).

7. Q: How does your factory do regarding quality control?

A: We always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained SGS, CE certificate.

8. Q: How is the training and after sales service?

A:

Training:

Machine should be placed in position and main power connected prior to setup and training at customer site. Customer should pay for travel plus related expenses (may include hotel, airfare, and rental car etc.) We also welcome customer send people here for training how to operate machines.Training CD or Manuals are available.

After sale service:

this shall be done by the seller. Seller will provide all kinds of technical support to the buyer by telephone, fax or email free of charge. After one-year guarantee period, we assure you life-long maintenance.

9. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Zhangjiagang city (beside to Shanghai).You can fly to Shanghai Hongqiao or PVG airport directly. All our clients, from home or abroad, are warmly welcome to visit us!