- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DIYFIA

-

Name:

-

190mm 4 blades water well tricone drilling PDC drill bit

-

Certification:

-

bs

-

Function:

-

Water well drilling , mining drilling

-

O.D dimenter:

-

178mm-216mm

-

Blades Qty:

-

3-6 blades

-

Avalible Insert Type:

-

Spherical, sharp and flat type

-

Insert Qty:

-

19pcs with 1308 strong

-

Thread Standard:

-

API 2 3/8" Pin Thread

Quick Details

-

Applicable Industries:

-

Drilling machine& drilling tools

-

Weight (KG):

-

15

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

DIYFIA

-

Name:

-

190mm 4 blades water well tricone drilling PDC drill bit

-

Certification:

-

bs

-

Function:

-

Water well drilling , mining drilling

-

O.D dimenter:

-

178mm-216mm

-

Blades Qty:

-

3-6 blades

-

Avalible Insert Type:

-

Spherical, sharp and flat type

-

Insert Qty:

-

19pcs with 1308 strong

-

Thread Standard:

-

API 2 3/8" Pin Thread

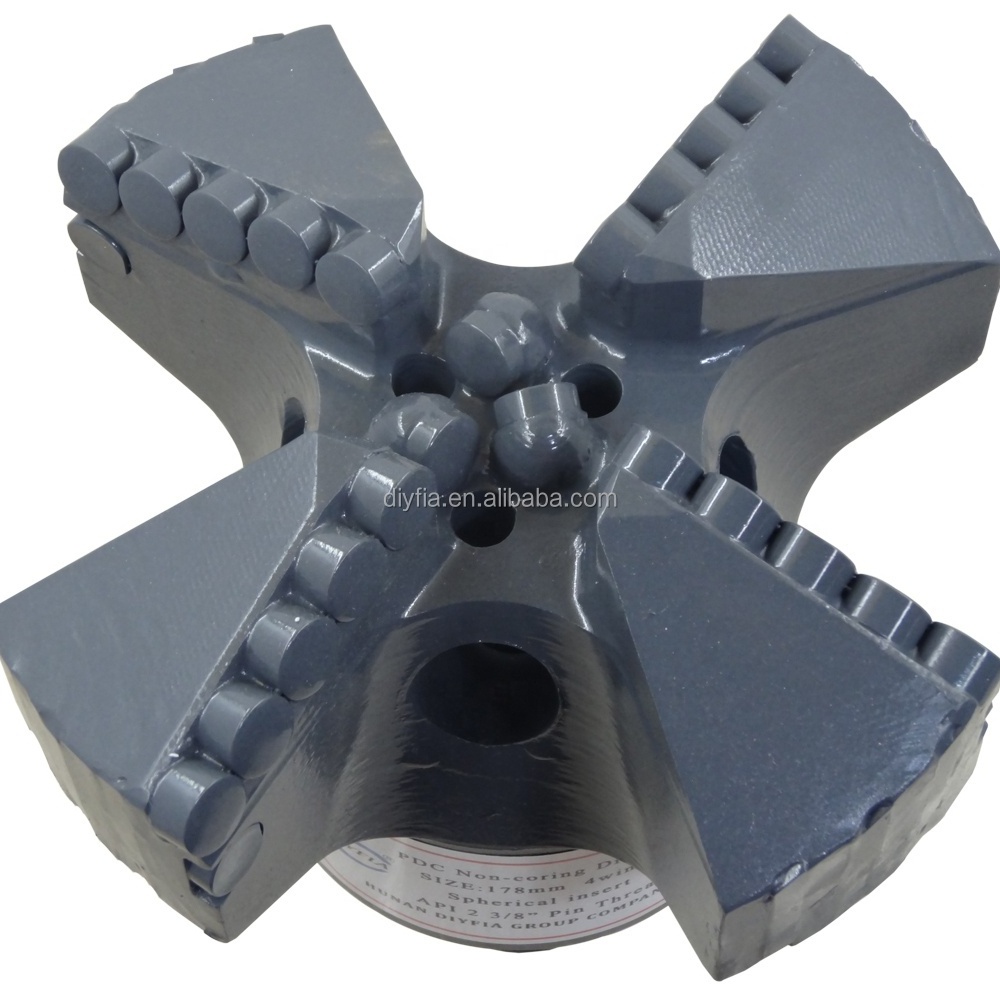

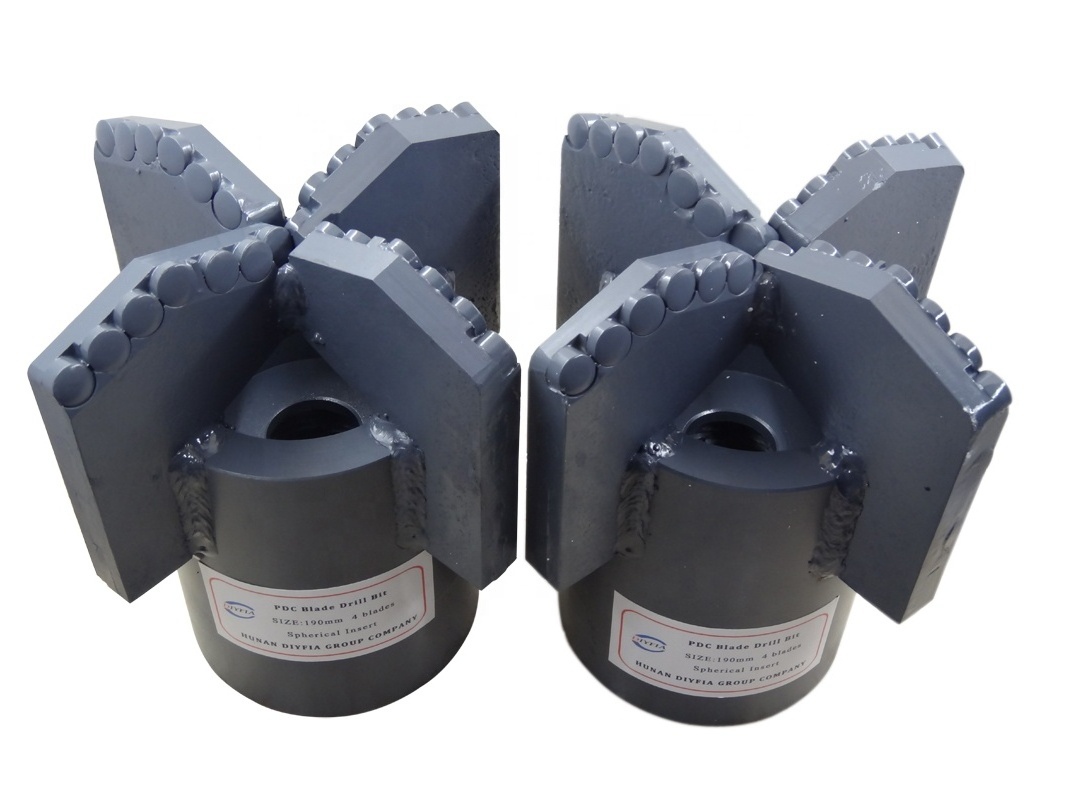

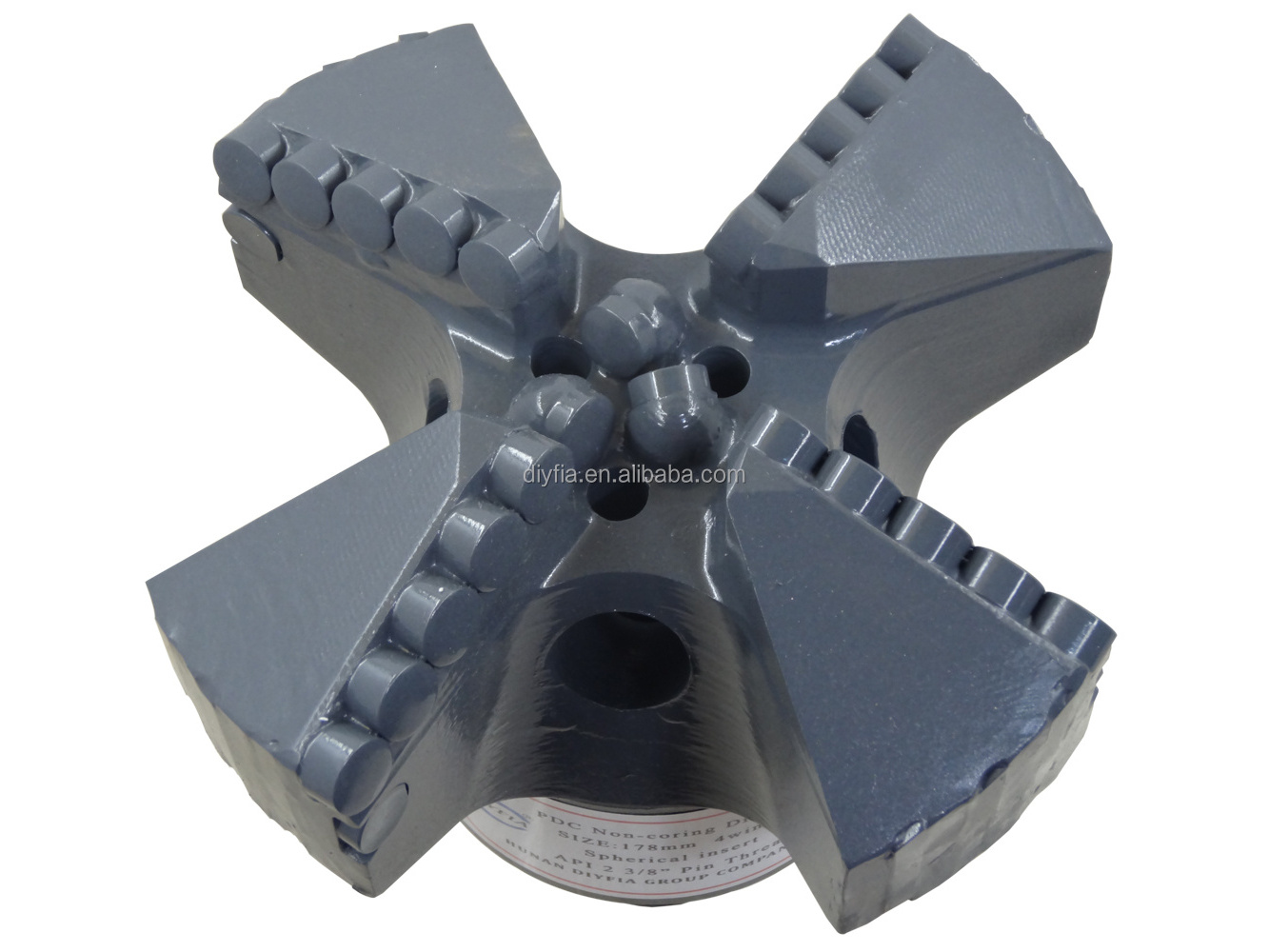

178mm 190mm 216mm 4 blades water well drilling PDC Non-Coring concave bit

PDC bits are the new bits with the characteristics of high wear resistance, high impact resistance, anti-ramps, mud-pack, high penetration rate. After using on site, it proves that PDC bits have advantages in high speed, deep footage, long life, steady work, few accident, good well bore quality when sneaking in hard or soft foundation.

2. Different PDC Insert cutters type for choose on the PDC drill bit:

3. Details descreption for PDC bits:

4. Dimensions of PDC Drill Bit

|

Specification of oil Drill Bit |

|||

|

Item |

Size ( mm ) |

Item Name |

Size (mm) |

|

Non-coring Drill Bit |

42 |

Coring Drill Bit |

65 |

|

Non-coring Drill Bit |

46 |

Coring Drill Bit |

75 |

|

Non-coring Drill Bit |

48 |

Coring Drill Bit |

78 |

|

Non-coring Drill Bit |

56 |

Coring Drill Bit |

94 |

|

Non-coring Drill Bit |

60 |

Coring Drill Bit |

94 |

|

Non-coring Drill Bit |

65 |

Coring Drill Bit |

98 |

|

Non-coring Drill Bit |

75 |

Coring Drill Bit |

100 |

|

Non-coring Drill Bit |

94 |

Coring Drill Bit |

113 |

|

Non-coring Drill Bit |

98 |

Coring Drill Bit |

132 |

|

Non-coring Drill Bit |

100 |

Coring Drill Bit |

133 |

|

Non-coring Drill Bit |

113 |

Coring Drill Bit |

153 |

|

Non-coring Drill Bit |

133 |

Coring Drill Bit |

173 |

|

Non-coring Drill Bit |

143 |

Multiple-cones Drill Bit |

94 |

|

Non-coring Drill Bit |

153 |

Multiple-cones Drill Bit |

98 |

|

Non-coring Drill Bit |

156 |

Multiple-cones Drill Bit |

113 |

|

Non-coring Drill Bit |

216 |

Multiple-cones Drill Bit |

133 |

|

Non-coring Drill Bit |

243 |

Anchor Drill Bit |

28 |

|

Non-coring Drill Bit |

312 |

Anchor Drill Bit |

32 |

We also can design PDC bits according to customer requirements, such as different geology conditions, special strata and so on.

5.

Our Company pas atention to produce quality and abides to credit, and also does the best to provide the quality produdcts and excellent service to customer. To build good after-sale service system, we draw up the Quality Guarantee according to the industrial standards combining field experience.

| Diamond Drill Bits |

1. Size, and / or technical parameters(matrix etc.) are different from the requirements of clients' purchase order.

|

Replace |

|

2. Thread can not fit clients' barrel.

|

Repair or replace | |

|

3. Break down a piece from matrix, and the volume of the piece exceed 2mm*2mm*2mm, and such break is not caused by drilling.

|

Replace

|

|

|

4. Matrix falling not caused by drilling.

|

Replace or return | |

|

5. Groove on matrix caused by manufacturer.

|

Replace or return

|

|

|

6. Drilling speed is obvious slower than congener products caused by manufacturer.

|

Raplace,and each item quantity does not exceed 3pieces. | |

|

7. Bit life is obvious short caused by manufacturer.

|

||

|

8. Breaking down of matrix, falling matrix, groove and short bit life caused by operating reasons-drill rod sticking, premature failure of the bit crown and hole-bottom not to be cleaned.

|

Be excluded from Qulity Guarantee | |

|

9. Short bit life or no penetration caused by drilling machine, drilling techniques or parameters.

|

||

|

10. Properly worn and the matrix is finished.

|

||

|

11. Thread damaged or distorted due to improper operation.

|

||

|

12. Steel body cracked in drill.

|

Replace or return

|

|

| Reaming shell |

1. Thread is not correct.

|

Replace or return. |

|

2. Steel body creacked in drill.

|

||

|

3. PCD Strips falling.

|