- Product Details

- {{item.text}}

Quick Details

-

Power:

-

4850 W

-

Dimension(L*W*H):

-

1000*1600*2100

-

Weight:

-

10000 KG

-

Product name:

-

Cotton disposable makeup remover fabric roll making machine

-

Raw material:

-

Cotton/Spunlace fabric

-

Application:

-

Face cleaning

-

Color:

-

Easy to Operate

-

Function:

-

Composite

-

Related machine:

-

Waste recycling machine

Quick Details

-

Voltage:

-

380v

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YG

-

Power:

-

4850 W

-

Dimension(L*W*H):

-

1000*1600*2100

-

Weight:

-

10000 KG

-

Product name:

-

Cotton disposable makeup remover fabric roll making machine

-

Raw material:

-

Cotton/Spunlace fabric

-

Application:

-

Face cleaning

-

Color:

-

Easy to Operate

-

Function:

-

Composite

-

Related machine:

-

Waste recycling machine

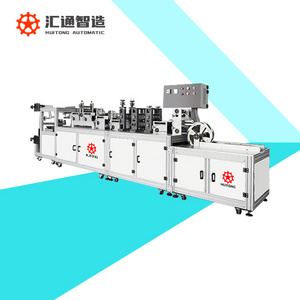

Cotton disposable makeup remover fabric roll making machine

Product Details

Production process: opening, carding, compositing, rolling and rewinding.

1. cotton box delivery: the cotton box is connected with the carding machine. The function is to feed the fiber into the carding machine, which is evenly loosened and mixed, to ensure the continuous and uniform supply of cotton, so as to make the carding process continuous.

2. carding parts: carding cotton is the use of carding machine, with the aid of needle movement, carding small cotton bundles as single fiber state, further removing impurities and non spinnable short fibers, making the fiber parallel straight, and finally made of single fiber cotton.

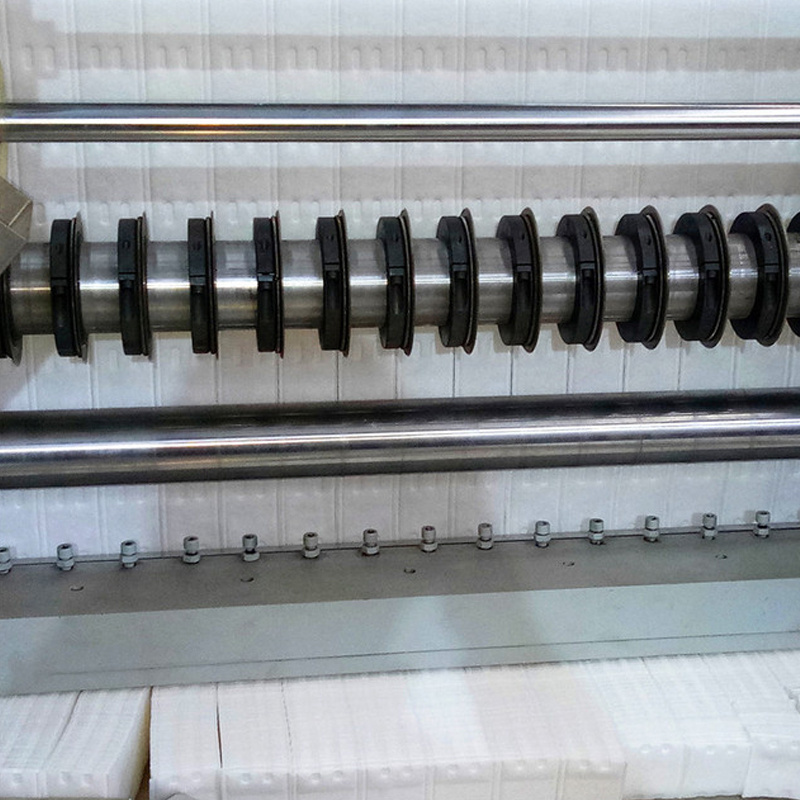

(1) the pre-carding part includes the parts of the needle roller, the cotton roller, the feeding board, the dust removal knife and the small leakage bottom.

2. Main carding part include cylinder, cover, doffer and large leakage.

3. The sliver part includes cotton stripper, bugle, roller and loop.

3. Compositing rolling part: the frequency conversion netting machine is matched with the carding machine,the double-layer Spunlaced cloth is combined to form the upper and downer non-woven fabrics, and is sent to the next process after rolling.

4. rewinding part: determine the width and thickness of the required products and wrap up the finished products.

| Model | Product width | Output |

| YG1260 | 1000mm | 2 Ton/day |

| YG-1860 | 1600mm | 2.5 Ton/day |

| YG-2260 | 2100mm | 3.5 Ton/day |