- Product Details

- {{item.text}}

Quick Details

-

Product Material:

-

A356,A380 ,ZL101,ZL102..

-

Process:

-

casting aluminium

-

Surface treatment:

-

polish

-

Application:

-

auto parts

-

Delivery Time:

-

30-45days

-

colour:

-

as your requests

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DongRun

-

Model Number:

-

aluminium machinery parts

-

Product Material:

-

A356,A380 ,ZL101,ZL102..

-

Process:

-

casting aluminium

-

Surface treatment:

-

polish

-

Application:

-

auto parts

-

Delivery Time:

-

30-45days

-

colour:

-

as your requests

Zhejiang Dongrun Casting Industry Co.,Ltd

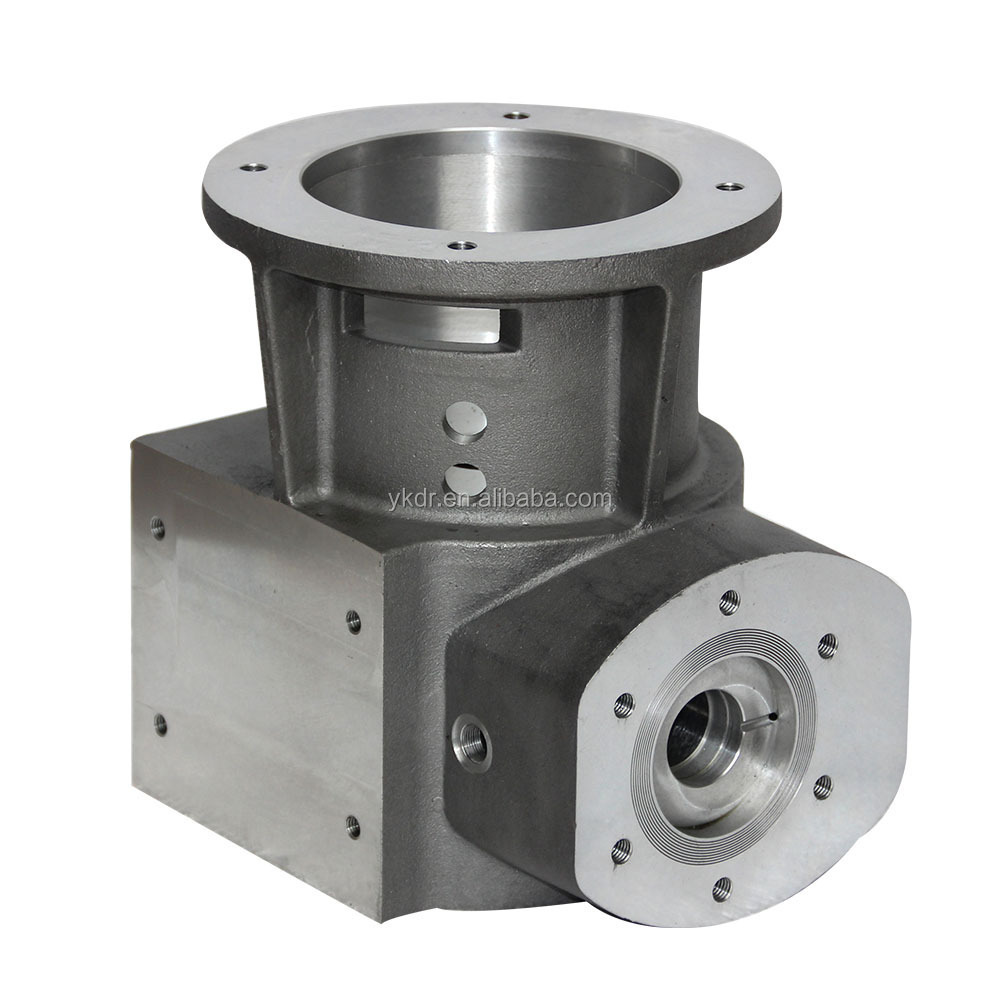

aluminum die casting Supplier t6 aluminum casting automobiles spare part low price die casting product aluminum enclosure

Company Introduce:

We(Dong run ) are the professional manufacture of Casting products in Yongkang city,zhejiang provice ,which start business on 1995, but we have been in the casting business for more than 20 years.And we are experienced to deal with all different kinds of casting products .

Just one point: We are special in CASTING LINE

In short:We are such kind one factory that supply casting products according to your samples or your drawings.

Our Product Progress:

Range of application e specially for:

(1)Mechnical properties:

Automotive parts/railroad parts/medical parts

marine parts/ pump body/valve parts,

(2)Architectural

Architectural parts /furniture parts / lighting parts And so on

Feature:

| Material |

1.Sand casting&Gravity casting&Low pressure die casting |

| Process | Sand casting, Gravity casting, high pressure die casting, low pressure die casting and CNC Machining casting. |

| Designs |

1.As per the customer's drawings 2.As per the customer's samples |

| Process |

Drawing&Samples

→

Mould making

→Gravity casting

→Duburring

→Drilling&threading

→

CNC Machining

→Polishing

→Surface Treatment

→Assembly

→Quality Inspection

→Packing

→Shipping

|

| Equipment of Casting |

1.High pressure die casting machining: 125T/180T/250T/280T/500T/800T/1250T 2.Gravity casting machine: 5 production lines 3.Low pressure die casting machining: 1 production line 4.Sand casting machine: 6 production lines 5.Degassing equipment and opportunities to refine the material 6.Machining: 5Sets CNC Machines;3 sets Milling machines; 3 sets Turning machines; 10 sets drill and tap machines |

| Testing facility | spectrometer, tensile test machine, hardness test machine, CMM dimension report |

| Certificate | ISO9001:2008/Rosh/SGS |

| Standard | ASTM, DIN,JIS, EN, ISO, GB standards |

| Software | Pro/E,UG, Solidworks, Auto CAD, PDF |

| Precision machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

| Finished | Polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing. |

| Product | All kinds of aluminum casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on |

| Advantage |

1.With more than 20years experiencesin Aluminum casting;

2.Have four casting types; 3.Near Sea Port and Air Port; 4.Passed ISO9001:2008/Rosh/SGS 5.From Casting to Finished surface, Owned casting, polishing and plating workshops, We can offer Good quality and strict delivery time. 6.With samples and order: We can offer dimension report, Chemical composition and Mechanical properties 7.Control material with spectral and thermal analysis equipment (density and processing) 8.Spectral analysis of raw material and liquid melt, batch before casting. |

| Inspection |

1.Foundry in-house

2.Third Party inspection available upon requirement |

| Packing | Carton Box with Pallet/Wooden Box/Steel Pallet |