- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

depends on material

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SUDA

-

Weight (KG):

-

4500 KG

-

Laser-type:

-

Fiber Laser

-

Control system:

-

Cypcut System

-

Laser source:

-

RAYCUS GW MAX IPG

-

Cooling system:

-

Water Cooling System

-

Positioning Accuracy:

-

±0.05

-

Laser Cutting Head:

-

WSX

-

Voltage:

-

380V /3PH/50 HZ

-

Cutting materials:

-

Carbon Steel Pipe

-

Function:

-

Cutting Tube Metal Materials

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

168m/min, 168m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

depends on material

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SUDA

-

Weight (KG):

-

4500 KG

-

Laser-type:

-

Fiber Laser

-

Control system:

-

Cypcut System

-

Laser source:

-

RAYCUS GW MAX IPG

-

Cooling system:

-

Water Cooling System

-

Positioning Accuracy:

-

±0.05

-

Laser Cutting Head:

-

WSX

-

Voltage:

-

380V /3PH/50 HZ

-

Cutting materials:

-

Carbon Steel Pipe

-

Function:

-

Cutting Tube Metal Materials

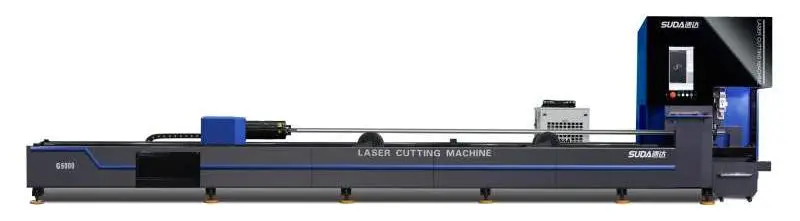

Product Description

|

Items

|

|

Parameters

|

|

||

|

Model

|

|

G6000 Series

|

|

||

|

Laser Source

|

|

Max/Raycus

|

|

||

|

Power

|

|

1000w 1500w 2000w 3000w(can be customized)

|

|

||

|

Linear Rial

|

|

LAPPING/SMG

|

|

||

|

Servo Motor

|

|

Delta/On the way Servo System

|

|

||

|

Cutting Head

|

|

WSX

|

|

||

|

Control System

|

|

NC STUDIO/CYPCUT3000S

|

|

||

|

Pipe Length

|

|

6000mm

|

|

||

|

Laser Media

|

|

Fiber Laser

|

|

||

|

Voltage Requirements

|

|

220v or 380v/50Hz~60Hz

|

|

||

|

Aiming Positioning

|

|

Red Dot

|

|

||

|

Cutting Thickness

|

|

Depend On the Materials

|

|

||

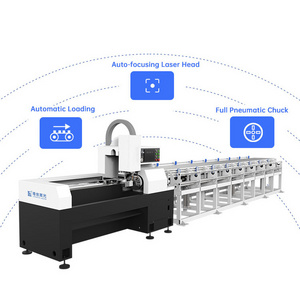

Main Parts

CYPCUT 3000S

Fscut3000s is a control system developed for pipe processing. It supports high-precision and high-efficiency cutting of square pipe, round pipe, racetrack type and elliptical stretch pipe, angle steel and channel steel. It is an upgraded version of fscut3000.

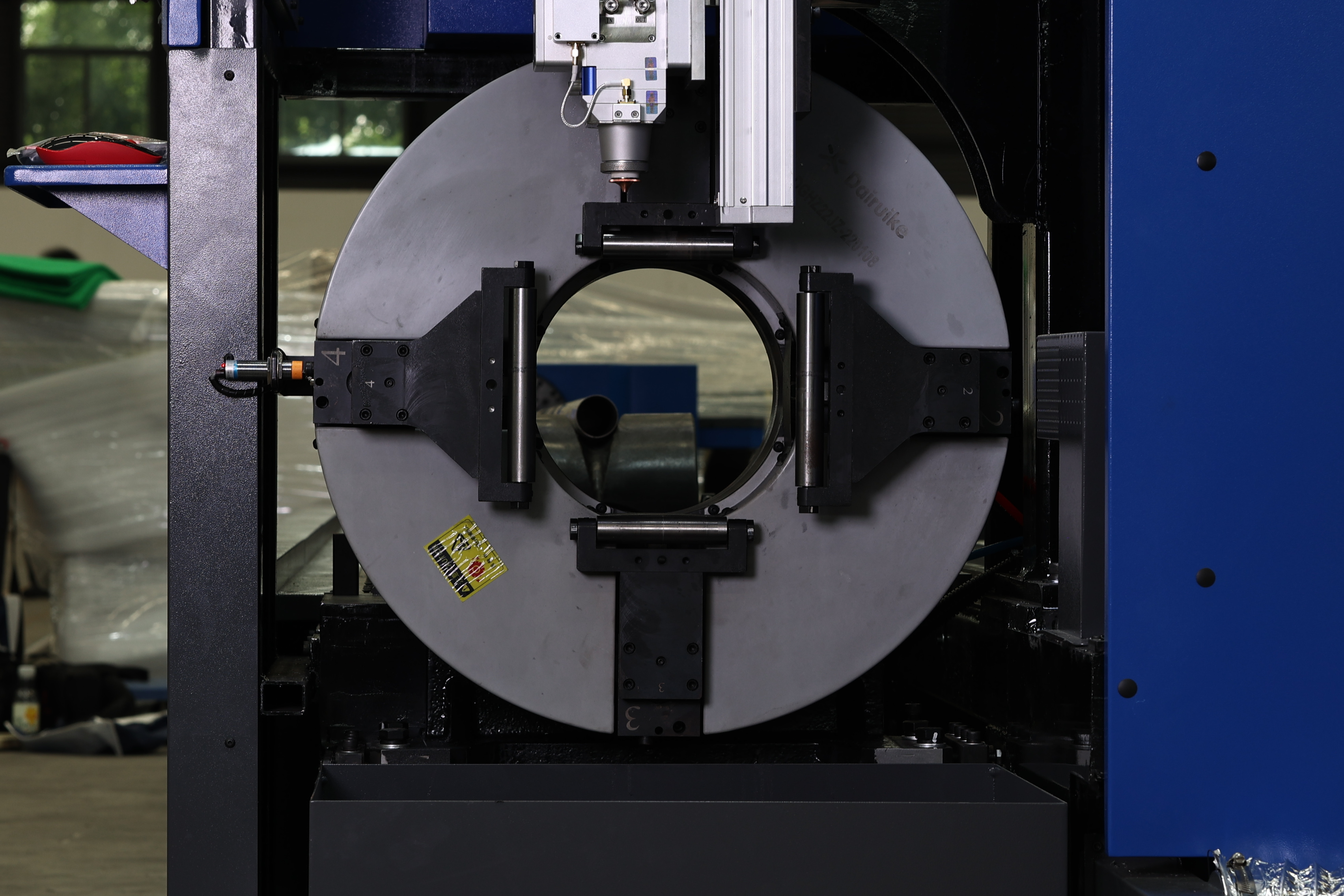

Dairuike

Dairuike 220mm pneumatic integrated double chuck

,

Compared with ordinary chucks, the working efficiency of Dairuike chucks will be improved a lot, for example, in terms of clamping. And the practical service life will be much longer.

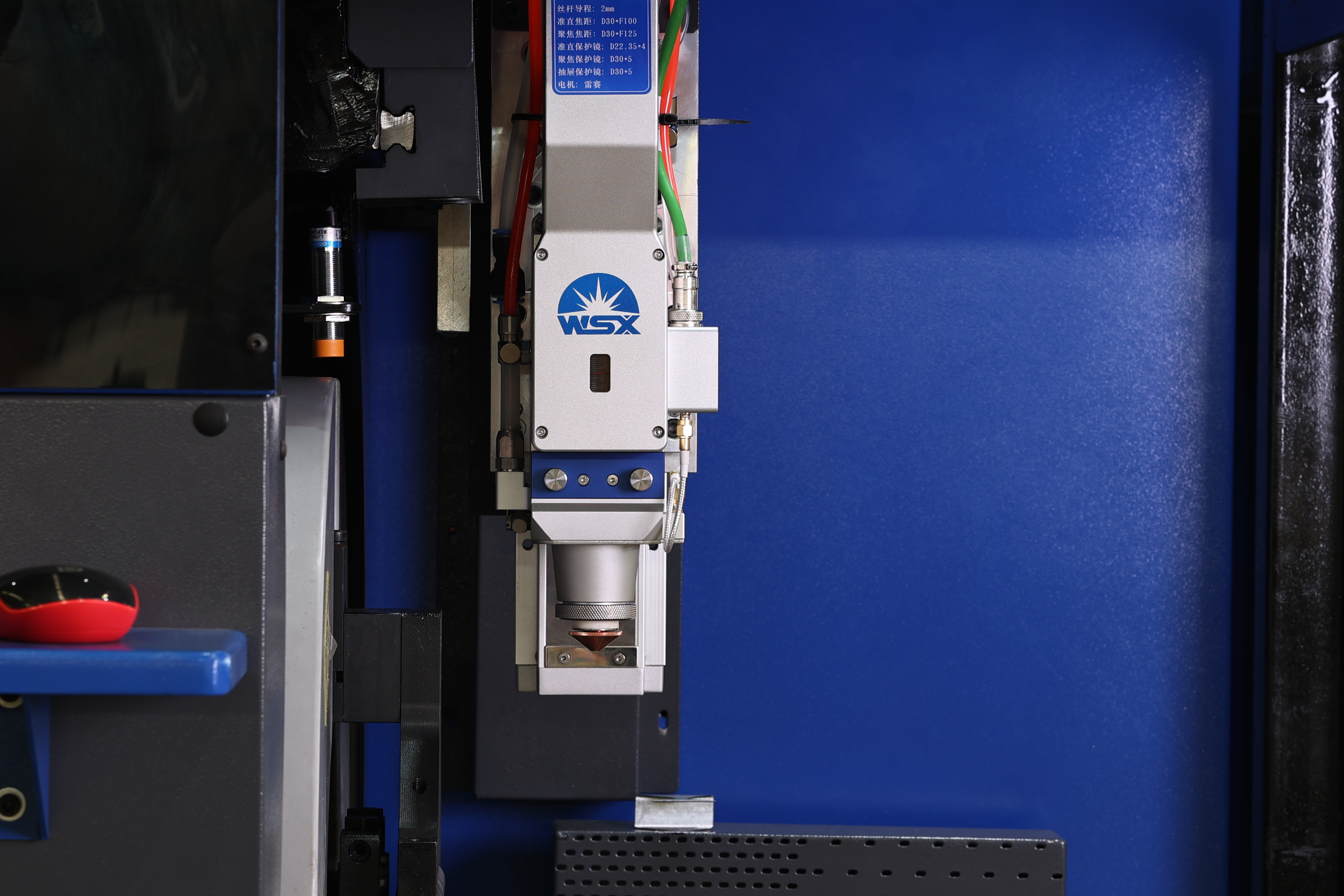

WSX KC15 cutting head

This cutting head has strong advantages in the application of medium power large format fiber laser cutting. The internal structure of the laser head is completely sealed, which can prevent the optical part from being polluted by dust. Equipped with various lasers with QBH connectors.

LAPPING guide rail

LAPPING products have applied for dozens of patents for better product quality and customer experience. Now the products have the advantages of high speed, miniature, ultra long, low noise, high precision, smooth movement, good synchronization, long durability and so on.

Applications&Samples

Features

1) Adopt industrial heavy duty steel structure, undergoes numerical control high-temperature heat treatment, to ensure long-term use of no deformation, suitable for high-power laser operation.

2) Adopt NC pentahedron machining, milling, boring, tapping and other machining processes to improves assembly precision of the machine tool and ensure running precision and stability of equipment.

3) Configure with Japan THK high-precision liner rail for all axis, running smoothly, wear-resistant and dust-proof, and equipped with automatic oil supply.

4) XY axis configured with Korea LEADRACK high accuracy grinding type gear rack, Z axis are transmitting by high accuracy rolling ball screw, equipment precision is higher.

5) Adopt Shanghai CYPCUT 3000S series professional pipe cutting system to support cycle processing, high precision of software operation.

6) Four-axis adopts France Schneider AC servo drive system, X-axis 1KW, Y-axis 3KW, Z-axis 750W, W-axis (front chuck 2KW, back chuck 3KW)

7) Adopt Shenzhen WSX automatic focusing cutting head, pipe material deviation automatically compensates.

8) Professional double pneumatic chuck, material diameter is 10-220mm.

2) Adopt NC pentahedron machining, milling, boring, tapping and other machining processes to improves assembly precision of the machine tool and ensure running precision and stability of equipment.

3) Configure with Japan THK high-precision liner rail for all axis, running smoothly, wear-resistant and dust-proof, and equipped with automatic oil supply.

4) XY axis configured with Korea LEADRACK high accuracy grinding type gear rack, Z axis are transmitting by high accuracy rolling ball screw, equipment precision is higher.

5) Adopt Shanghai CYPCUT 3000S series professional pipe cutting system to support cycle processing, high precision of software operation.

6) Four-axis adopts France Schneider AC servo drive system, X-axis 1KW, Y-axis 3KW, Z-axis 750W, W-axis (front chuck 2KW, back chuck 3KW)

7) Adopt Shenzhen WSX automatic focusing cutting head, pipe material deviation automatically compensates.

8) Professional double pneumatic chuck, material diameter is 10-220mm.

Our Company

Certificates

Why Choose Us

FAQ

Leave Messages Below To Get Latest Quotation

Hot Searches