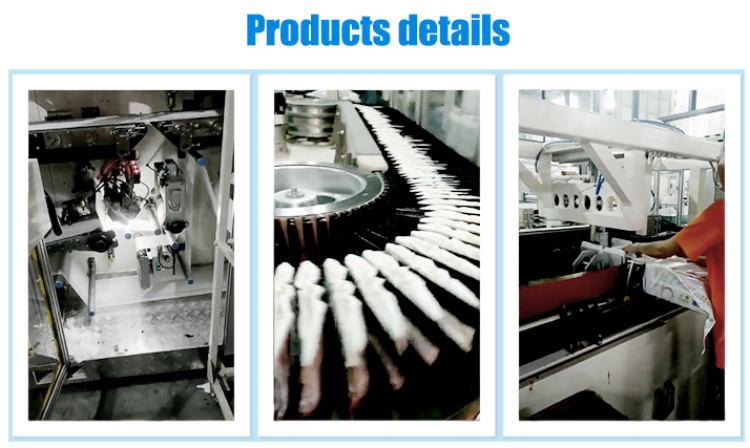

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

260KW

-

Dimension(L*W*H):

-

22*2*3.5m

-

Weight:

-

2000 kg

-

Product name:

-

Baby Diaper Production Line

-

Finished Products:

-

Baby Diaper

-

Raw material:

-

Nonwoven

-

Application:

-

Auto Diaper Paper Industry

-

Type:

-

Semi-automatic

-

Speed:

-

150-200pcs/min

-

Color:

-

Customized Color

-

Advantage:

-

High Effiency

-

Control system:

-

PLC+Touch Screen

-

Power Source:

-

380V 50HZ 3Phase

Quick Details

-

Production Capacity:

-

200 pcs/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Voltage:

-

380V

-

Power:

-

260KW

-

Dimension(L*W*H):

-

22*2*3.5m

-

Weight:

-

2000 kg

-

Product name:

-

Baby Diaper Production Line

-

Finished Products:

-

Baby Diaper

-

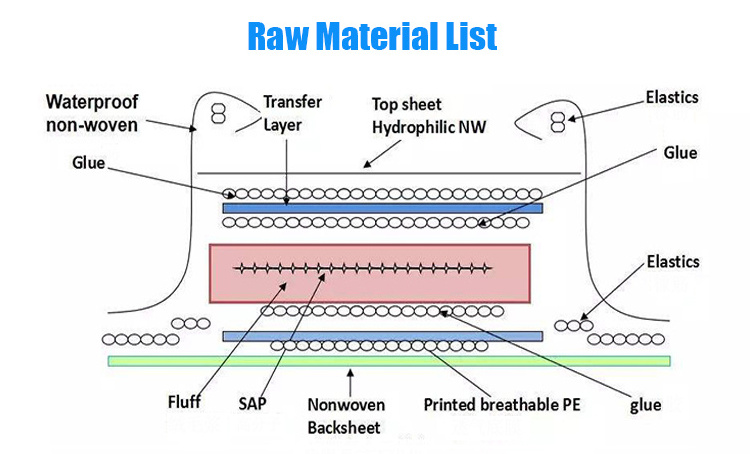

Raw material:

-

Nonwoven

-

Application:

-

Auto Diaper Paper Industry

-

Type:

-

Semi-automatic

-

Speed:

-

150-200pcs/min

-

Color:

-

Customized Color

-

Advantage:

-

High Effiency

-

Control system:

-

PLC+Touch Screen

-

Power Source:

-

380V 50HZ 3Phase

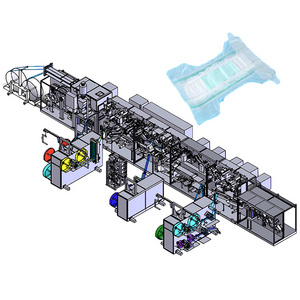

| Main Parameter | |

| Overall Size | 30*6*4m |

| Machine Size | 22*2*3.5m |

| Design Speed | 600pcs/min |

| Stable work speed | 450-500pcs/min |

| Pass percentage | 98% |

| Power source | 380V,50HZ |

| Machine capacity | about 260kw |

| Air pressure | 0.6-0.8Mpa |

| Machine weight | about 60T |

| Configuration | |

| Product size | S: 390x280 M: 450x320 L: 500x320 XL: 525x330 |

| Safety system | It has safety device on the operating side, matched with urgent stop switch.High audio fan uses sound insulation or silencer. |

| Control system | PLC control system,Operating on the touch screen,Configure HDTV monitor |

| Materials corrective system | Germany BST automatic web guide system (optional). |

| Drive system | Three-axis or full servo |

| Product structure | Up&Down Tissue, Fluff core(mix with SAP), ADL, Backsheet, Front tape, Topsheet, Leg cuff N.W., Side Tape, Waistband. |

| Tension system | Up&Down Tissue ADL, Back sheet, Top sheet, Cuff N. W., are adopt A&B shaft active unwinding by inverter motor. |

| Packing Way | Equipped with the stacker at the request of client. |

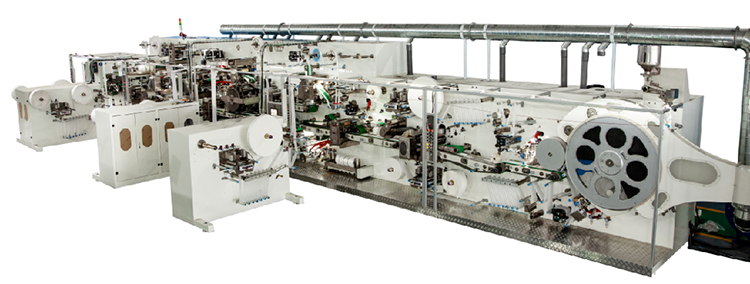

Full servo T shape baby diaper production:

| Configuration | |

| Product size | 380x280 420x320 480x320 520x340 |

| Safety system | Safety guard installed at the operating side, with security identifier, emergency stop switch at per segment, Driven side is equipped with the radiator system and safety wire. |

| Control system | PLC control system,Operating on the touch screen,Configure HDTV monitor |

| Materials corrective system | Germany BST automatic web guide system (optional). |

| Drive system | Full servo drive, digital size change, ensure, run synchronized at full process. The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. |

| Product structure | Top(bottom) tissue paper,sap core,ADL,hydrophobic NW(leg cuff),topsheet NW,PE film,spandex,frontal tape,elastic nonwoven(zero-waste),S cut |

| Tension system | Tissue paper, cotton core (SAP), Top sheet nonwoven, ADL,PE film,back&wing release paper,packing film A&B shaft unwinding by Inverter motor |

| Packing Way | Auto stacker as customized design (one push two exit.). |

South African customer working site

The production line of 200 pieces/min of baby diapers per minute for South African customers, the finished product absorbs quickly, is comfortable and soft, and the fully automatic production line of this machine saves manpower and creates huge economic value for investors.

1. Packaging:

Packed by standard import & export wooden cases or carton boxes.

2. Shipping:

By logistics; by automobile; by train; by shipping; by air etc.