Model:

DLG110

Main motor:

22kw

Cutting motor:

1.1kw

Feeding motor:

0.75kw

Water pump:

0.37kw

Heating:

18kw

Dimension(m):

2.5*0.9*1.8

Net weight:

1260kg

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

130kw

-

Dimension(L*W*H):

-

25*5*5m

-

Weight:

-

5500 KG

-

commercial pasta machine:

-

short pasta/macaroni

-

Machine Warranty:

-

One Year after installation

-

Machine Operate:

-

3-5 workers

-

High quality new design:

-

Vacuum Pump Extruder

-

Machine Craft:

-

Extrusion

-

Machine Output capacity:

-

200-250kg/h

-

pasta texture:

-

transparency,shine

-

pasta/macaroni shapes:

-

screw,shell,tube,whelk

-

Application:

-

Industrial pasta machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SBN

-

Voltage:

-

380V

-

Power:

-

130kw

-

Dimension(L*W*H):

-

25*5*5m

-

Weight:

-

5500 KG

-

commercial pasta machine:

-

short pasta/macaroni

-

Machine Warranty:

-

One Year after installation

-

Machine Operate:

-

3-5 workers

-

High quality new design:

-

Vacuum Pump Extruder

-

Machine Craft:

-

Extrusion

-

Machine Output capacity:

-

200-250kg/h

-

pasta texture:

-

transparency,shine

-

pasta/macaroni shapes:

-

screw,shell,tube,whelk

-

Application:

-

Industrial pasta machine

Product Description

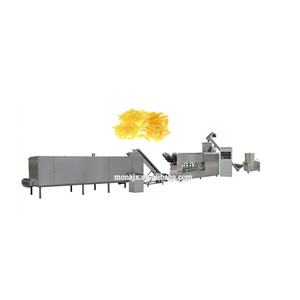

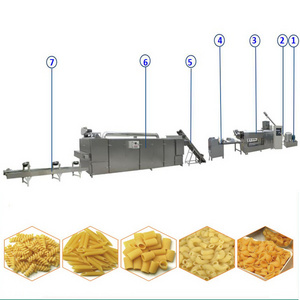

Pasta/macaroni production line

Pasta is a traditional Italian cuisine, and gradually become the staple food all over the world. Saibainuo offer complete pasta production lines for a wide range of typical short-cut pasta shapes.

Process as below:

The raw material are mixed with precise ingredients and water. The extruding stage is carried out with a specially designed single-screw system to ensure optimal semolina mixing, compression and extrusion. Once the dough is kneaded to the required consistency, it goes through fitted dies to produce the required shapes and cut to verious length. After drying, the pasta is cooled and stabilized in the industrial pasta machine and then transported to storage or packaged directly.

2.Features:

(1). Spaghetti Pasta Machine has the advantage of rational design, high automatic degree and accuracy control.

(2).The main body material is stainless steel, which is easy to be cleaned.

(3).The screws material is 38CrMnAl, which is wear-resisting.

(4).Our project is turn-key. We will send our engineer to your factory, install and debug the equipments, and train your operators.

(5).The temperature and rotating speed can be controlled and adjusted

3.Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

4.Capacity: 100-120kg/h &280-300kg/h

5.Flow chart: Mixing system---Extrusion system----Cutting system---Drying system---Cooling System --Packing system

Process as below:

The raw material are mixed with precise ingredients and water. The extruding stage is carried out with a specially designed single-screw system to ensure optimal semolina mixing, compression and extrusion. Once the dough is kneaded to the required consistency, it goes through fitted dies to produce the required shapes and cut to verious length. After drying, the pasta is cooled and stabilized in the industrial pasta machine and then transported to storage or packaged directly.

(1). Spaghetti Pasta Machine has the advantage of rational design, high automatic degree and accuracy control.

(2).The main body material is stainless steel, which is easy to be cleaned.

(3).The screws material is 38CrMnAl, which is wear-resisting.

(4).Our project is turn-key. We will send our engineer to your factory, install and debug the equipments, and train your operators.

(5).The temperature and rotating speed can be controlled and adjusted

3.Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

4.Capacity: 100-120kg/h &280-300kg/h

5.Flow chart: Mixing system---Extrusion system----Cutting system---Drying system---Cooling System --Packing system

Specification

Single screw extruder

Patent:

Vacuum Pump.For the pasta ,the biggest problem is with bubbles and air inside.With the vacuum pump,which can extract air from feeding part,so there will be no any air and bubbles inside.

Function:

1.Specially decide single-screw system extreude and form the raw material into different sizes and shapes.

2.Controlling system,feeding system,extruding system,heating system, water cooling system, cutting system,lubricating,system,vacuum technology,

Features:

1.Screw material is 38CrMoAl with nitriding treatment, the hardness is 60HRC.

2.Barrel material is alloy steel, hardness is 52HRC.

3.The gear box has forced lubrication system.

4.All the motor is controled by Inveter, which can save power and protect the extruder.

Function:

1.Specially decide single-screw system extreude and form the raw material into different sizes and shapes.

2.Controlling system,feeding system,extruding system,heating system, water cooling system, cutting system,lubricating,system,vacuum technology,

Features:

1.Screw material is 38CrMoAl with nitriding treatment, the hardness is 60HRC.

2.Barrel material is alloy steel, hardness is 52HRC.

3.The gear box has forced lubrication system.

4.All the motor is controled by Inveter, which can save power and protect the extruder.

|

Model

|

Power

|

Capacity

|

Dimension

|

|

DLG 110

|

130kw

|

100-120kg/h

|

25*3*3m

|

|

DLG 150

|

230kw

|

250-300kg/h

|

35*4*4m

|

Packing & Delivery

Hot Searches