- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Tian Qiao

-

Model Number:

-

AWS E6013 E7018

-

Operating Current:

-

DC AC

-

Application:

-

Building

-

Color:

-

Blue Red Green Grey

-

Keyword:

-

Welding Rode Electrode

-

Standard:

-

AWS Standards

-

OEM:

-

Provide OEM Service

-

Advantage:

-

Easy Restrike Arc, Small Splash

-

Trade Term:

-

FOB CIF CFR EXW

-

Product Name:

-

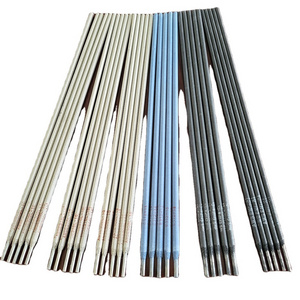

stainless steel welding rod e308-16 welding electrode e6013 e7018

-

Usages:

-

Welding Mild Steel

Quick Details

-

Material:

-

Stainless steel

-

Welding Current:

-

50-240A

-

Operating Temperature:

-

Standard Temperature

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Tian Qiao

-

Model Number:

-

AWS E6013 E7018

-

Operating Current:

-

DC AC

-

Application:

-

Building

-

Color:

-

Blue Red Green Grey

-

Keyword:

-

Welding Rode Electrode

-

Standard:

-

AWS Standards

-

OEM:

-

Provide OEM Service

-

Advantage:

-

Easy Restrike Arc, Small Splash

-

Trade Term:

-

FOB CIF CFR EXW

-

Product Name:

-

stainless steel welding rod e308-16 welding electrode e6013 e7018

-

Usages:

-

Welding Mild Steel

Products Description

|

Items

|

C

|

Mn

|

Si

|

S

|

P

|

Ni

|

Cr

|

Mo

|

Cu

|

|

Requirements

|

≤0.08

|

0.5-2.5

|

≤1.0

|

≤0.03

|

≤0.04

|

11.0-14.0

|

17.0-20.0

|

2.0-2.5

|

≤0.75

|

|

Typical

|

0.04

|

0.96

|

0.68

|

0.010

|

0.028

|

11.65

|

19.0

|

2.41

|

0.08

|

MECHANICAL PROPERTIES OF ALL WELD METAL:

|

Items

|

Rm/MPa

|

A/%

|

|

Requirements

|

≥520

|

≥25

|

|

Typical

|

595

|

42

|

TYPICAL OPERATING PROCEDURES: (AC OR DC+)

|

Diameter(mm)

|

2.5

|

3.2

|

4.0

|

5.0

|

|

Current(A)

|

50-80

|

80-110

|

110-160

|

160-200

|

Application

:

It is suitable for welding 06Cr17Ni12Mo2 stainless steel equipment working in organic and inorganic acid (non-oxidizing acid) medium. It can also be used for welding high chromium steels or dissimilar steels that cannot be heat-treated after welding.

Attention:

1. Before welding, the electrode shall be baked at 320-350℃ for 1 hour and used as needed.

2. Remove rust, grease, moisture and other impurities before welding.

3. DC power supply is recommended, because the depth of current welding is relatively shallow, the current should not be too large, so as to avoid redness and cracking of the skin.

4. Reduce the heat input as much as possible, and the swing amplitude of the electrode should not be too large.

5. Preheat and keep the temperature between channels below 150℃.

Packing & Delivery

Hot Searches