- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RF

-

Model Number:

-

W-1

-

Product Name:

-

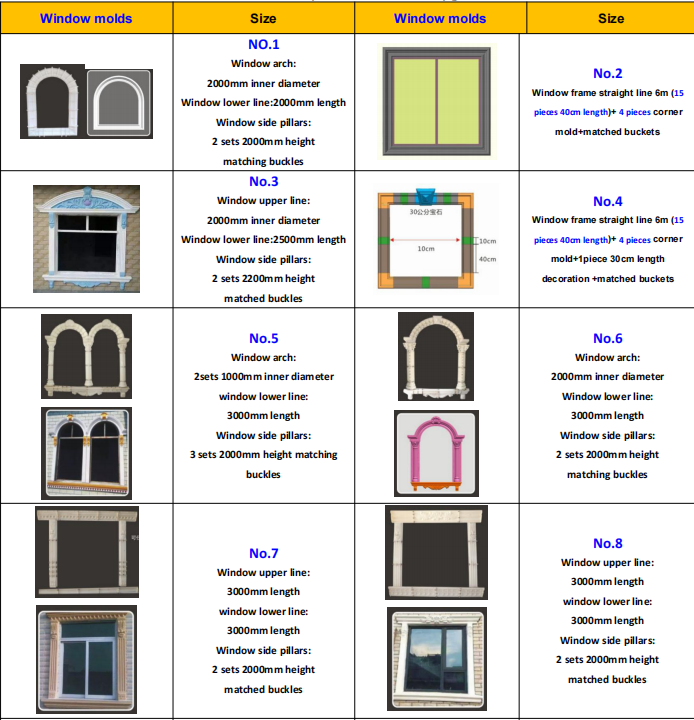

Window molds

-

Material:

-

Plastic(ABS)

-

Mould Life:

-

2-3 Years

-

Color:

-

White

-

Size:

-

Rich

-

MOQ:

-

1 Piece

-

Package:

-

woven Bags

-

Mold type:

-

Plastic injection mold

-

Service:

-

Provide Techinical Support

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Other

-

Project Solution Capability:

-

Others

-

Application:

-

Hotel

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RF

-

Model Number:

-

W-1

-

Product Name:

-

Window molds

-

Material:

-

Plastic(ABS)

-

Mould Life:

-

2-3 Years

-

Color:

-

White

-

Size:

-

Rich

-

MOQ:

-

1 Piece

-

Package:

-

woven Bags

-

Mold type:

-

Plastic injection mold

-

Service:

-

Provide Techinical Support

Product Overview

window mold

The window

mold is an outdoor building material. ABS plastic

fiberglass

mold is used for concrete casting window

molds

. There are many specifications for you to choose. Different specifications have different prices. Welcome to order!

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Product Name

|

window mold

|

|

2

|

Material

|

Plastic(ABS)

|

|

3

|

Application

|

Outdoor Decoration

|

|

4

|

Mould Life

|

2-3 Years

|

|

5

|

Color

|

White

|

|

6

|

Size

|

rich

|

|

7

|

Package

|

Woven Bags

|

|

8

|

Service

|

Provide Techinical Support

|

|

9

|

Mold type

|

Plastic injection mold

|

|

10

|

MOQ

|

1 Piece

|

Product Description

Product Display

Manufacturing Technique

Fixed mold

1.Punch holes around the window mold and insert steel bars.Insert a steel bar every 10-15 cm.

2.Nail short steel bars diagonally inside the window mold.

Pouring concrete into mold

3.After the mold is fixed, pour the upper and lower line parts first.

4.After pouring the concrete, tap the mold with a hammer lightly to shake out the air bubbles and make the concrete evenly fill the mold.

Pouring concrete into mold

5.Install and fix the left and right window side column molds.

6.Leave the stigma part of the left and right window side columns for pouring and height adjustment.

7.Pouring concrete into side column molds

7.Pouring concrete into side column molds

Demold

8.Pouring the stigma part

9.Demolding after the concrete is dry for 1-2 days.(The demolding time is adjusted according to the local weather and temperature)

10.Paint(if needed)

10.Paint(if needed)

Recommend Products

Our company

Zhengzhou Renfa Machinery and Equipment Co.,Ltd

Our company is a professional manufacturer specialized in plastics molds.

We have more than 10 years experience in molds designing and manufacturing, with registered capital of $1,500,000 , to ensure the development of high quality molds. We are the manufacturer that direct from factory outlet, we will give you the lowest price with High quality guaranteed.

In the field of foreign trade,Our main export products are: Led curbstone ,plastic brick molds,paving molds,and all kinds of molds according to customer's requirement.

We have already built a stably and friendly long term cooperation relationship with many countries , such as Japan/Brazil/Negeria etc. We provide high- quality products.

Hope we will be your long term partner!

Our company is a professional manufacturer specialized in plastics molds.

We have more than 10 years experience in molds designing and manufacturing, with registered capital of $1,500,000 , to ensure the development of high quality molds. We are the manufacturer that direct from factory outlet, we will give you the lowest price with High quality guaranteed.

In the field of foreign trade,Our main export products are: Led curbstone ,plastic brick molds,paving molds,and all kinds of molds according to customer's requirement.

We have already built a stably and friendly long term cooperation relationship with many countries , such as Japan/Brazil/Negeria etc. We provide high- quality products.

Hope we will be your long term partner!

SALES AND SERVICE NETWORK

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

1. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2.what can you buy from us?

Roman pillar mold, window trim mold, baluster mold, garden concrete decoration mold, planter pot mold, concrete stamp mold,

artificial stone mold, plastic paving mold, plastic curbstone mold, gypsum line mold, wall panel mold, lamp panel mold, interior

decoration mold, hollow brick machine and related equipment.

3. why should you buy from us not from other suppliers?

Our company have 15 years of production experience,have exported our product to many countries in the world. so we have rich

experience to service our customer.

4. what services can we provide?

Accepted Delivery Terms: FCA, FOB, CFR, CIF, DDU, DDP;

Accepted Payment Currency: USD,CNY;

Accepted Payment Type: T/T, Western union, Paypal, Visa card, Credit card;

Language Spoken: English,Chinese

Hot Searches