- Product Details

- {{item.text}}

Quick Details

-

Model:

-

XHD-55/75X1250

-

Screw L/D:

-

30:1

-

Screw Speed:

-

50-150 rpm

-

Width of effective film:

-

1000mm/2x500mm

-

Total Power:

-

78kw

-

Thickness:

-

12-50 μm

-

Layer structure:

-

AB/ABA

-

Extruded Capacity:

-

80-150kg/h

-

Output:

-

2.5-3.0 T/24H

-

Automatic Grade:

-

Fully Automatic

-

Certification:

-

ISO14009001 /SGS/CE/CCC

-

Power:

-

78kw

Quick Details

-

Screw Design:

-

two- screw

-

Place of Origin:

-

Guangdong, China

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Model:

-

XHD-55/75X1250

-

Screw L/D:

-

30:1

-

Screw Speed:

-

50-150 rpm

-

Width of effective film:

-

1000mm/2x500mm

-

Total Power:

-

78kw

-

Thickness:

-

12-50 μm

-

Layer structure:

-

AB/ABA

-

Extruded Capacity:

-

80-150kg/h

-

Output:

-

2.5-3.0 T/24H

-

Automatic Grade:

-

Fully Automatic

-

Certification:

-

ISO14009001 /SGS/CE/CCC

-

Power:

-

78kw

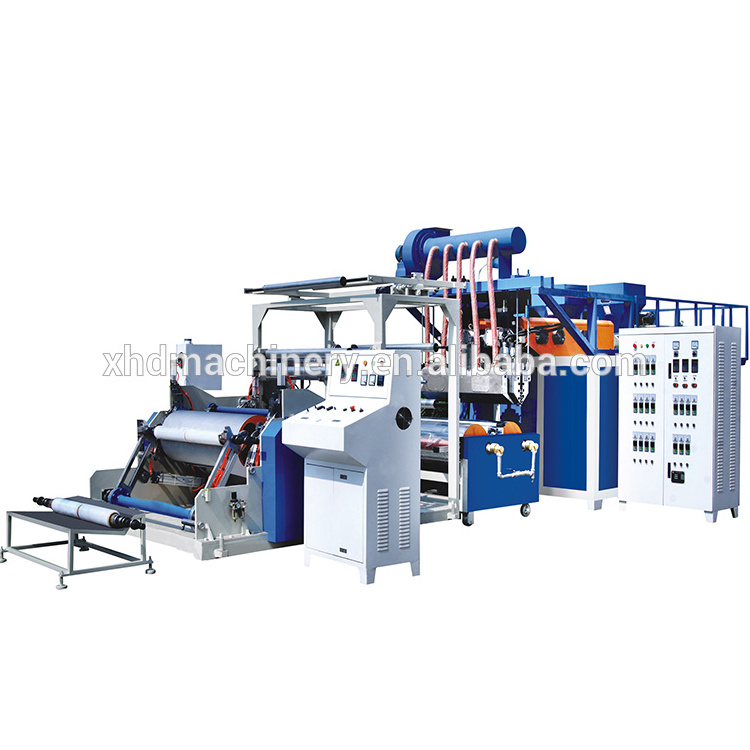

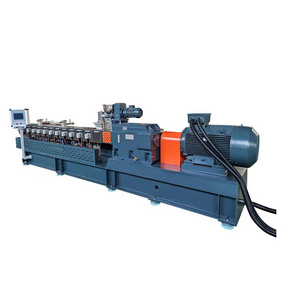

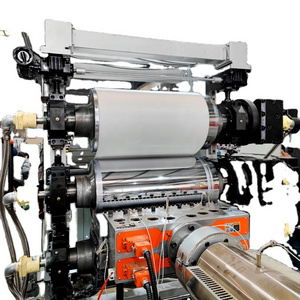

Customized Pallet Extruder Machine Production line for Stretch Film

The machine group is a cast stretch film machine group with high-plasticizing, easy operating, long-life ,energy saving and it's modified and designed on the years' experience on the cast equipment manufacturing and the production experience from the customers, combined with the advanced technology from oversea. The machine group is mainly for the production of LLDPE film, LDPE film, PE film, and CPE film etc. It adopts advanced intelligent industrial controlling system, with automatic hidden cutting saw, automatic cutting and roll change, auto paper core loading and unloading system(option upon request),which ensures the easy and safe operation, a tighter and more even roll winding. All the designs ensure the film quality, enhance the production efficiency, lower down production cost and create more value. The installation of swing system on the subsidiary machine can enhance the evenness and appearance of the film rolls which make the products more competitive.

| Model | XHD-55/75X1250 |

| Screw Diameter | 55/75 mm |

| Screw L/D | 30:1 |

| Screw Speed | 50-150 rpm |

| Width of effective film | 1000mm/2x500mm |

| Total Power | 78kw |

| Thickness | 12-50 μm |

| Tolerance of thickness | ≤±5% |

| Extruded Capacity | 80-150kg/h |

| Output | 2.5-3.0 T/24H |

| Structure of film layers | AB /ABA Co-extruded,2 layers |

| Film material | LLDPE/ LDPE |

| Electric power supply | Customized, Standard is 380V/50HZ/3P |

| Paper core size | φinner76 |

| Cooling temperature | 18-25 degree |

| Total weight | 8T |

| Machine dimension | 7500*3000*3000mm |

Guangdong Xinhuida Machinery Technology Co., Ltd, which is specialized in making cast stretch cling film related machinery, the width from 500mm to 2000,single layer to multi layers. Our company is combined with machine design, R&D, manufacturing, sales and after sales services. We are honest and conscientious to supply our home and abroad customers with high quality, low power saving, high comparative advanced equipment.

We formed a team with responsible and professional machine designers, automatization senor engineers, technique testing engineers, sales team, after-sales technique specialist since we established. During this more than 10 years, we introduce the highly-sophisticated detection equipment and install the machine with imported original spare parts, besides, we are constantly innovating and developing according to the technology of European same field machines. Presently our machines is anywhere at home and abroad, we constantly export to USA, Russia, Spain, Turkey, Saudi Arabia, Korea, Malaysia, India etc, more than 50 countries and regions.

As the continuous professional technology and R&D introduced, now we have our own patent and trademark which all meet the ISO international certification and 3C certification. We are based on developing our advantage and combining our equipment features to provide our customers the high efficient machine to win market, leading the peer and building XHD professional brand which is praised by the global world.

We keep innovating, seeking common ground while reserving difference, emphasizing the development of humanity. We welcome all the new and old customers contacts to cooperate and develop together.

XHD Advantages

XHD Advantages

1.12 years’focus in cast stretch cling film machine.

2.Modern factory building area 30,000 m2

3.World advanced production technology and processing equipment.

4.More than 20 Senior engineers focus in technology innovation and improvement.

5.Cover most of China market for the stretch film industry and 100% leading market rate.

6.Exported to about 50 countries and areas,10 famous enterprise nominated supplie

1. 1 year warranty for all system.

2. 24 hour after-sale service hot line 400-833-5568

3. Technology support and installation vedio for machine

4. Our engineers can be sent to the overseas to train your workers for 7days

5. High quality film recipe sharing

6. We have a large team to serve for you and can solve your problem within 24 huors.

1.Q: Can we make both manual grade and machine grade stretch film?

A: Yes.

2.Q: Is this machine full automatic?

A: Yes. This machine is fully automatic.

3.Q: Can we also use recycled material in this machine?

A: Yes. You can use recycled material. But the more recycled material you add, the stretch film will not as stretchable and transparency as the raw material one. One of our customer in Russia used 100% recycled material. Of course, the design of the screw will be a little different.

4.Q: What's the spare parts?

A: We have spare parts list, which will be sent after receipt of your email.

5.Q: Is there any other material that we use add to make stretch film ?

A: It depends on your requirements. You can add MLLDPE (metallocene) to make the film more stretchable, especially used in pallet package. Or the glue to make the film more sticky.

6.Q: Can you help us to install the machine?

A: Yes. We will arrange the engineer from our after-sales service team to install the machine after it arrives in your factory.