Multiple

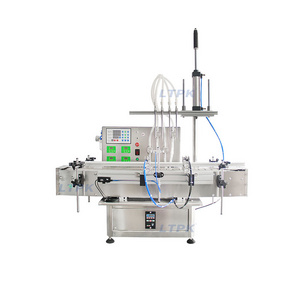

peristaltic pump with filling range 0.5-15ml.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.5%

-

Packaging Type:

-

Plastic Tube, Composite Tubes

-

Voltage:

-

AC 110/220V, 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DANREL

-

Dimension(L*W*H):

-

1310*1050*1760 mm

-

Weight:

-

550 KG

-

Delay Time/Weld time/Hold Time:

-

0.01-9.99 S

-

Working Pressure:

-

0.5-0.7 MPa

-

Horn Journey:

-

75MM

-

Advantages:

-

Digital, fully auto-tuning

-

Operation Mode:

-

Manual + Auto

-

Language:

-

English

-

Filling Volume:

-

1-15ML

-

Filling material:

-

Cream, Gel, Liquid, Ointment

-

Capacity:

-

20-35 tubes/min

-

Function:

-

5-Strip Tubes Filler and Sealer

Quick Details

-

Machinery Capacity:

-

6000 tubes per hour

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Oil, Liquid

-

Filling Accuracy:

-

0.5%

-

Packaging Type:

-

Plastic Tube, Composite Tubes

-

Voltage:

-

AC 110/220V, 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DANREL

-

Dimension(L*W*H):

-

1310*1050*1760 mm

-

Weight:

-

550 KG

-

Delay Time/Weld time/Hold Time:

-

0.01-9.99 S

-

Working Pressure:

-

0.5-0.7 MPa

-

Horn Journey:

-

75MM

-

Advantages:

-

Digital, fully auto-tuning

-

Operation Mode:

-

Manual + Auto

-

Language:

-

English

-

Filling Volume:

-

1-15ML

-

Filling material:

-

Cream, Gel, Liquid, Ointment

-

Capacity:

-

20-35 tubes/min

-

Function:

-

5-Strip Tubes Filler and Sealer

DANREL ULTRASONIC TUBE FILLING SEALING MACHINE

The process of tube sealing machine eliminates the use of glue and allows the thermoplastic parts to bond to itself. Ultrasonic sealing with the proper time setting and pressure is the fastest most reliable method for a variety of tube material sealing.

* Eliminate use of consumable material

* Produce airtight and watertight seams

* Increase production time

Main Features

1. Function: Filling, Sealing, Counting, Date coding.

Automatic detection: No tube no filling/no sealing/no counting

2. Auto rotary table six working stations for filling sealing, more efficient.

3. Anti drip filling machine to filling the 5 strips tubes at the same time,make the filling more accurate.

4. Adopt digital ultrasonic machine, stable output and performance, truly auto-tuning.

5. Machine body of stainless steel, meet with GMP requirement

6. PLC/HMI control, English Interface Touch screen, simple operation and parameters setting

7. This machine is sealing by ultrasonic, fast and nice looking, energy saving.

8. Main parts adopt imported components, Japan and Taiwan

9. Can connect the filling tank directly. More convenience use PLC to operate and adjust the filling weight.

10. Suitable for all kinds of plastic tubes, composite tubes, PE tubes.

Functions:

1. Tube Filling

2. Ultrasonic Sealing

3. Cutting (trimming)

4. Batch No Coding

5. PLC/HMI control, English/French/Espanol interface as request

6. 6 tube stations

7. Stainless steel body, Meet with GMP requirement

8. Meet with CE requirement.

|

Model No

|

DR-2015T

|

|

|

||

|

Ultrasonic Power

|

2600 W

|

|

|

||

|

Frequency

|

15 KHz

|

|

|

||

|

Power Supply

|

AC 110/220V, 50/60Hz

|

|

|

||

|

Delay Time

|

0.01-9.99 S

|

|

|

||

|

WeldTime

|

0.01-9.99 S

|

|

|

||

|

Hold Time

|

0.01-9.99 S

|

|

|

||

|

Driven Mode

|

Pneumatic

|

|

|

||

|

Stroke

|

75 MM

|

|

|

||

|

Working Pressure

|

0.5-0.7 MPa

|

|

|

||

|

Tube Height Range

|

50-250 MM

|

|

|

||

|

Filling Range

|

0.5-15ml for liquid

|

|

|

||

|

Working Station Number

|

6

|

|

|

||

|

Packing Dimension

|

L*W*H 1310*1050*1760 mm

|

|

|

||

|

Gross Weight

|

550 KGS

|

|

|

||

It's applicable to cosmetic, pharmaceutical, food, industry product and other soft tube sealing. Extensional organization of the machine is made of aluminium alloy and stainless steel.