- Product Details

- {{item.text}}

Quick Details

-

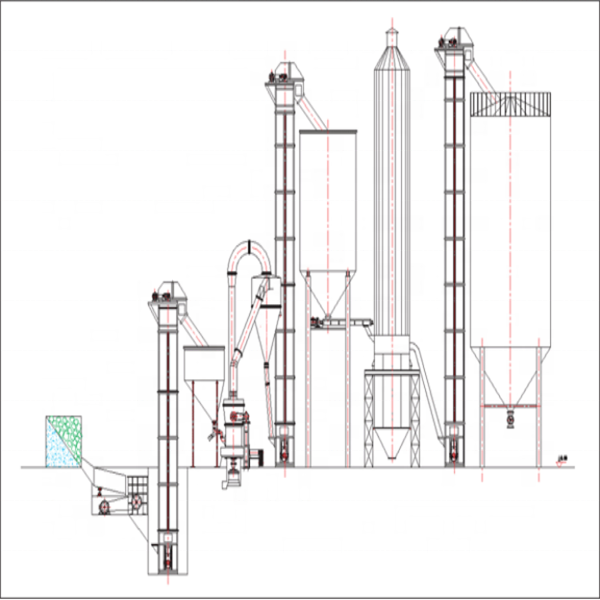

Dimension(L*W*H):

-

25*12*6m

-

Weight:

-

100 KG

-

Equipments 1:

-

Autoclave ,Elevator,Electromagnetic feeder

-

Equipments 2:

-

Heat Conductive Oil Furnace ,grinding mill

-

Feature:

-

Easy operation,automatic

-

Raw material:

-

Gypsum Ore , Gypsum Rock

-

Fuel:

-

Oil Gas etc

-

Calcination system:

-

gypsum frying boiler

-

Price:

-

Competitive

Quick Details

-

Capacity(t/h):

-

50-550 tons per day

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dafu

-

Dimension(L*W*H):

-

25*12*6m

-

Weight:

-

100 KG

-

Equipments 1:

-

Autoclave ,Elevator,Electromagnetic feeder

-

Equipments 2:

-

Heat Conductive Oil Furnace ,grinding mill

-

Feature:

-

Easy operation,automatic

-

Raw material:

-

Gypsum Ore , Gypsum Rock

-

Fuel:

-

Oil Gas etc

-

Calcination system:

-

gypsum frying boiler

-

Price:

-

Competitive

High quality gypsum plaster powder making machine , gypsum raymond mill , ring pulverizer for sale

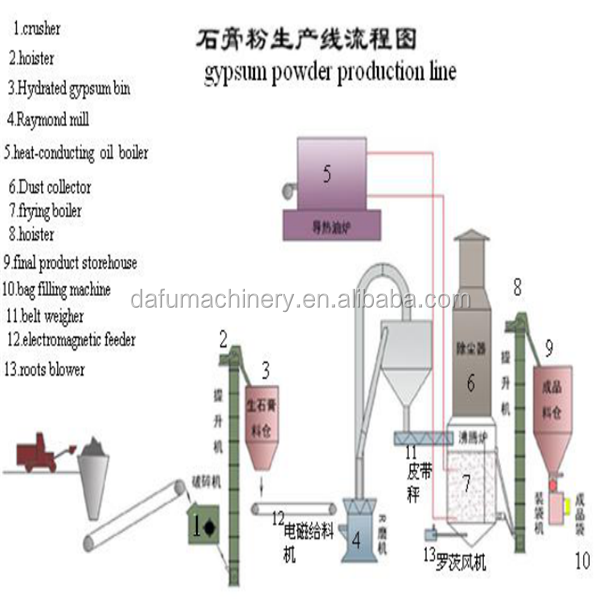

1.Introduction of the gypsum powder production line:

First grind and second bake. The largest advantage of this technique, compared with that of “first bake and second grind”, is energy consumption reduction. Large plaster stone shall be ground into powders with diameter less than 0.2mm, which increases the specific surface when calcining, enlarges the contact area with heat medium, improves calcinations heat exchange efficiency and lowers energy consumption greatly. This equipment has small bulk, large production capacity, and simple structure and is hard to destroy.

New-type gypsum frying boiler- ebullience calciner

First grind and second bake. The largest advantage of this technique, compared with that of “first bake and second grind”, is energy consumption reduction. Large plaster stone shall be ground into powders with diameter less than 0.2mm, which increases the specific surface when calcining, enlarges the contact area with heat medium, improves calcinations heat exchange efficiency and lowers energy consumption greatly. This equipment has small bulk, large production capacity, and simple structure and is hard to destroy.

The working principle of ebullience calciner:

The main part of the ebullience calciner is composed of small diameter cooling coil pipes. The heat transfer oil is piped into coil pipe and releases the heat into the furnace after exchanging heat. Roots blower is equipped at the bottom of the ebullience calciner, which can blow the cold air into the furnace, making the powder boiling in the furnace. And at the certain temperature, the powder, which has been dried, becomes the light that it can flow to the outlet automatically. The quality of the gypsum powder produced in this way is better and the content of crystallization water is high and easy to control the time of solidification. In addition, the machine is equipped with dry electrostatic precipitator , and the dust removal efficiency reaches over 95%, eliminating the dust pollution.

Heat-conducting oil boiler

Main characters:

1. High automaticity, prompt start and stop, high reliability.

2. High thermal efficiency, completely burning, stable output, better adaptability to variable load.

3. Compact structure, small area requirement.

4. Less auxiliaries, easy installation.

5. Less pollutant emission, can reach higher Environmental protection index.

Electrostatic dust collector

B esides the equipment mentioned above, design for the entire production line and auxiliary equipment election are provided, and technical engineers would be sent to the customer’s site for installation and debugging machine to guarantee qualified product.

1.Jaw crusher

2.Belt Conveyor

3.Gypsum powder grinding mill

|

Packaging Details: |

standard export packing, 20ft, 40ft container. equipment fittings,electric motor and power cabinet willbe packed in wooden case. bulk

|

|

Delivery Detail: |

30working days after receiving the payment

|

Our machines and equipments are packed in standard package that fit for long distance road transportation and shipping. We ensure our customers can receive the undamaged machine in good condition.

We are the professional manufacturer in Henan Zhengzhou. Our engineers have about 20 years experience in this industry. The capacity varies 20tons per day to 550tons per day. We give professional technical advice to every client. we will give our best service to meet your requirements.

How to decide the size/type of gypsum powder production line we need?

Kindly tell us the following information if you are interested in our machines:

1. The annual output capacity or daily output capacity?

2. The fuel used in the gypsum powder production line ?

If you are interested in themachineryby us, please Contact us or visit the website of the company for relevant prices and detailed technical parameters and specifications etc. Henan Dafu Mechanical Import and Export Co., Ltd. will assure you of our best service at all time!