- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380/440V/customer required

-

Dimension(L*W*H):

-

different

-

Weight:

-

6800 KG

-

Marketing Type:

-

Hot Product 2023

-

Keywords:

-

mineral separator

-

Name:

-

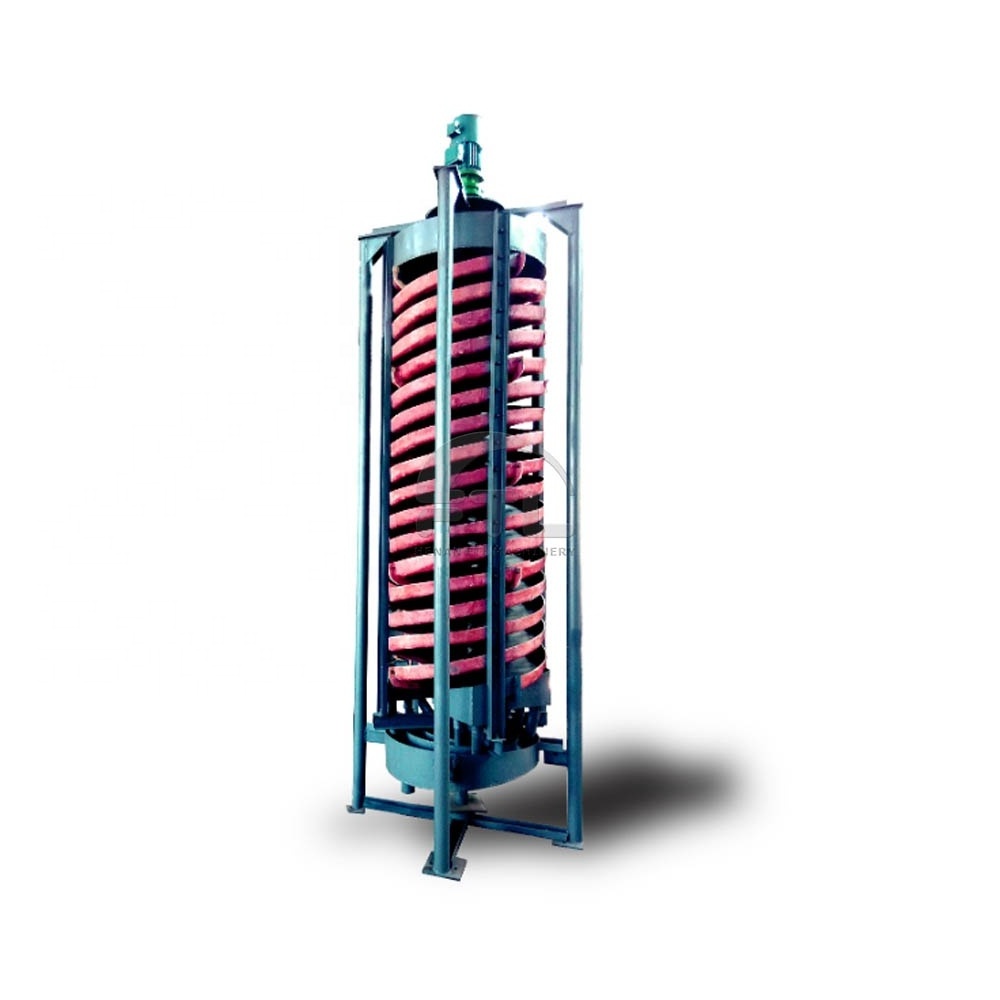

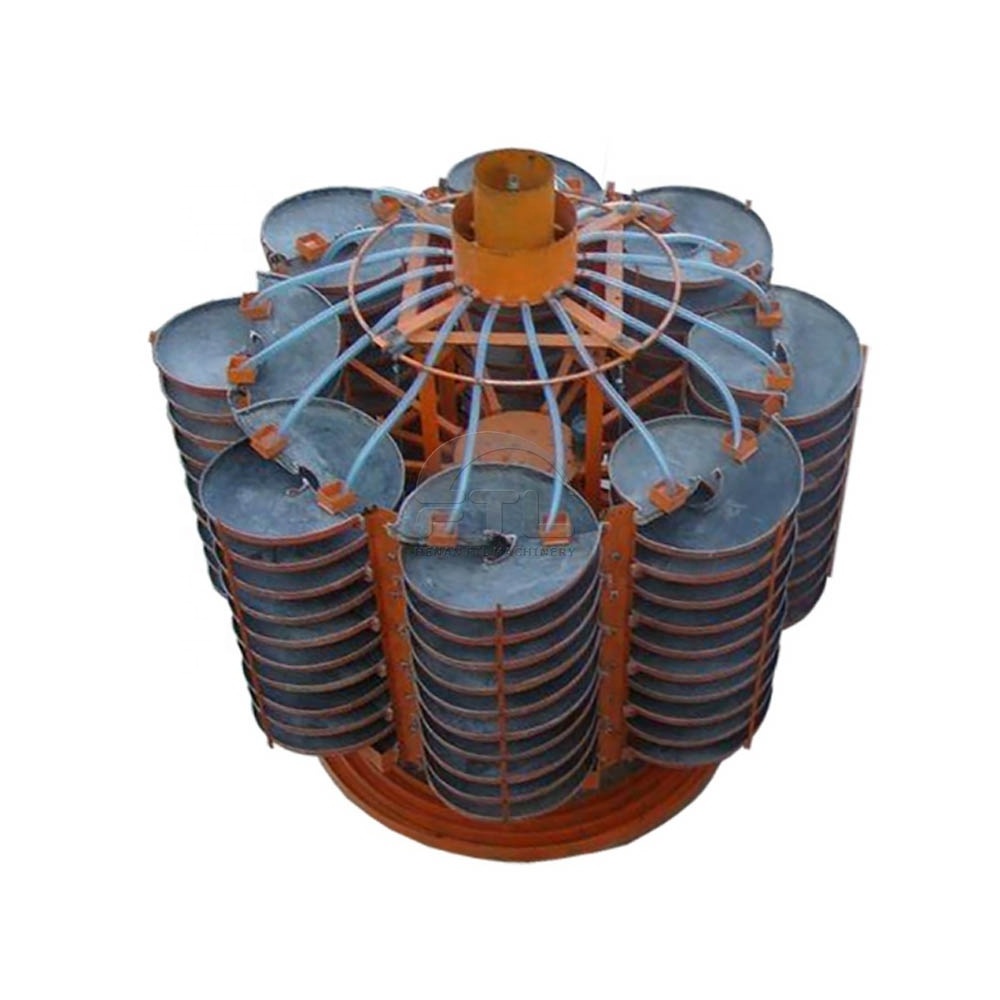

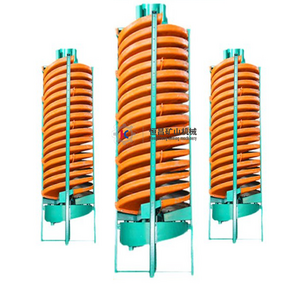

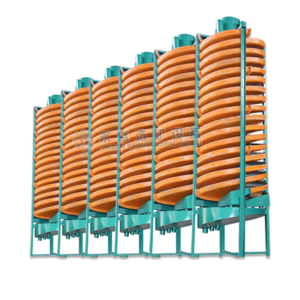

spiral chute

-

Gravity Separator:

-

yes

-

Application:

-

iron ore / ilmenite/chromite

-

Application 2:

-

sulphur/zirconium/rutile

-

application 3:

-

monazite/etrimfos/tungsten

-

application 4:

-

tin/tantalum

-

Local Service Location:

-

Russia/Kazakhstan/Uzbekistan/Egypt

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Production Capacity:

-

100%

-

Place of Origin:

-

China

-

Brand Name:

-

FTL

-

Voltage:

-

220/380/440V/customer required

-

Dimension(L*W*H):

-

different

-

Weight:

-

6800 KG

-

Marketing Type:

-

Hot Product 2023

-

Keywords:

-

mineral separator

-

Name:

-

spiral chute

-

Gravity Separator:

-

yes

-

Application:

-

iron ore / ilmenite/chromite

-

Application 2:

-

sulphur/zirconium/rutile

-

application 3:

-

monazite/etrimfos/tungsten

-

application 4:

-

tin/tantalum

-

Local Service Location:

-

Russia/Kazakhstan/Uzbekistan/Egypt

-

After-sales Service Provided:

-

Field installation, commissioning and training

Product Description

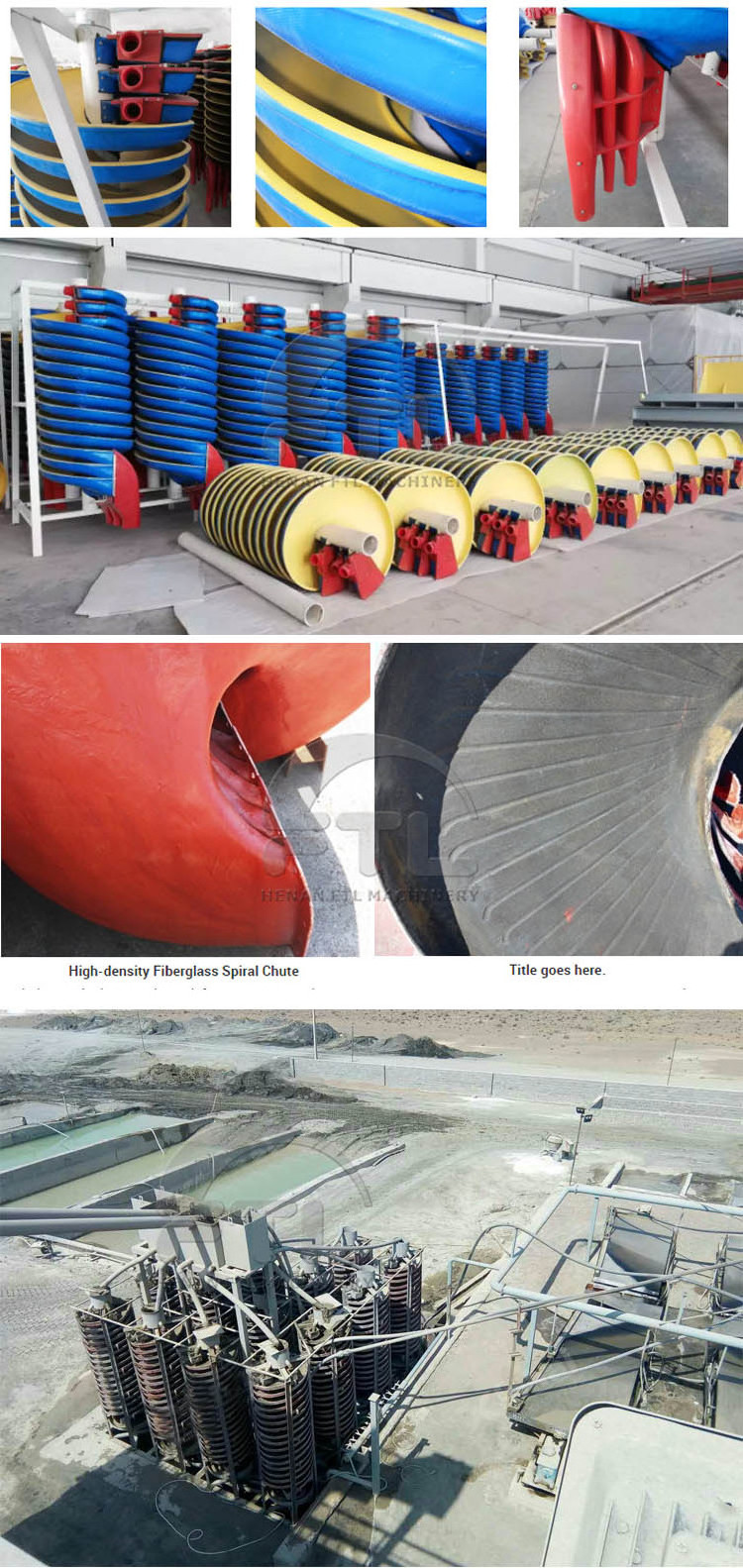

Spiral Chute Introduction

Spiral Chute Working Principle

Spiral Chute/ Spiral Separators, which are also called Spiral Concentrators, are gravity devices that separate minerals of different specific

gravity according to their relative movement in response to gravity, centrifugal force and other forces in the fluid medium. The heavy frictional forces slow their velocity. As a result, faster particles higher up in the flow. This creates a horizontal

density differentiation of the feed materials, with the heavy particles flowing along the inside walls of the channel, and the

faster lighter particles travelling higher up towards the outer rim. The discharge outlets are located on the inside of the

channel for removal of the heavier material. Separation precision can be improved by adding additional water during the

beneficiation process.

Specification

|

Model

|

5LL-2000

|

5LL-1500

|

5LL-1200

|

5LL-900

|

5LL-600

|

5LL-400

|

|

Outside dia (mm)

|

2000

|

1500

|

1200

|

900

|

600

|

400

|

|

pitch (mm)

|

1200

|

540, 720

|

900, 720, 540

|

675, 540, 405

|

450, 360, 270

|

240, 180

|

|

Pitch Dia Ratio

|

0.6

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.6, 0.45

|

|

Lateral slope

|

9°

|

9°

|

9°

|

9°

|

9°

|

9°

|

|

Maximum starts per column

|

2

|

4-2

|

4-2

|

4-2

|

2

|

2

|

|

Feeding Size (mm)

|

2-0.04

|

0.3-0.02

|

0.3-0.03

|

0.3-0.03

|

0.2-0.02

|

0.2-0.02

|

|

Feeding Density(%)

|

30-55

|

25-55

|

25-55

|

25-55

|

25-55

|

25-55

|

|

Capacity (T/H)

|

7-10

|

6-8

|

4-6

|

2-3

|

0.8-1.2

|

0.15-0.2

|

|

Length (mm)

|

2120

|

1560

|

1360

|

1060

|

700

|

460

|

|

Size Width (mm)

|

2120

|

1560

|

1360

|

1060

|

700

|

460

|

|

Height (mm)

|

5600

|

5230

|

5230

|

4000

|

2600

|

1500

|

|

Weight (Kg)

|

1200

|

800

|

600

|

400

|

150

|

50

|

Packing & Delivery

More machines for

Mineral Process Plant

FAQ

Q: what FTL Machinery can supply for you?

1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design & equipment, we also provide the infrastructure design; Electrical & pipeline system design,

etc. To help our clients complete the design of the whole plant;

3.After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on

site, to guarantee the output minerals perfectly meet your demands.

Q: What Information should customers give to us in order to let we provide you with efficient & suitable quotation and

assistance.

A:1. What type is the mining? Is it rock stone? or it is sand?

2. If rock stone,What is the general particle size(mm) of the raw ore?

3. What is the handling capacity(tons per hour) you plan to work with?

4.What is the elements of the raw ore? How much percent % of each minerals?

Q: Can we send the mineral samples to your company, let your company run the ore-dressing experiments test for us?

A: Yes, we can run the ore-dressing experiments for our customers. After the test, we will based on the results to give you the

reasonable flowchart, suitable solution and equipments selection. etc.

A: Yes, we can run the ore-dressing experiments for our customers. After the test, we will based on the results to give you the

reasonable flowchart, suitable solution and equipments selection. etc.

Q: How long is the warrenty of your equipments? Does your company supply the spare parts?

A: The warranty period of OASIS equipments is one year. And of course we will supply the spare parts for you for life-long time

at lowest cost.

A: The warranty period of OASIS equipments is one year. And of course we will supply the spare parts for you for life-long time

at lowest cost.

Q: If i need the complete mineral processing line. is OASIS able to help us build it?

A: Yes, we can help you combine a complete mineral processing line. and give you related professional advices as long as you

need.

There is a rich experience engineer team of us. we had already build many mining projects in China & Overseas. You can believe our quality and service.

A: Yes, we can help you combine a complete mineral processing line. and give you related professional advices as long as you

need.

There is a rich experience engineer team of us. we had already build many mining projects in China & Overseas. You can believe our quality and service.

contact me

Hot Searches