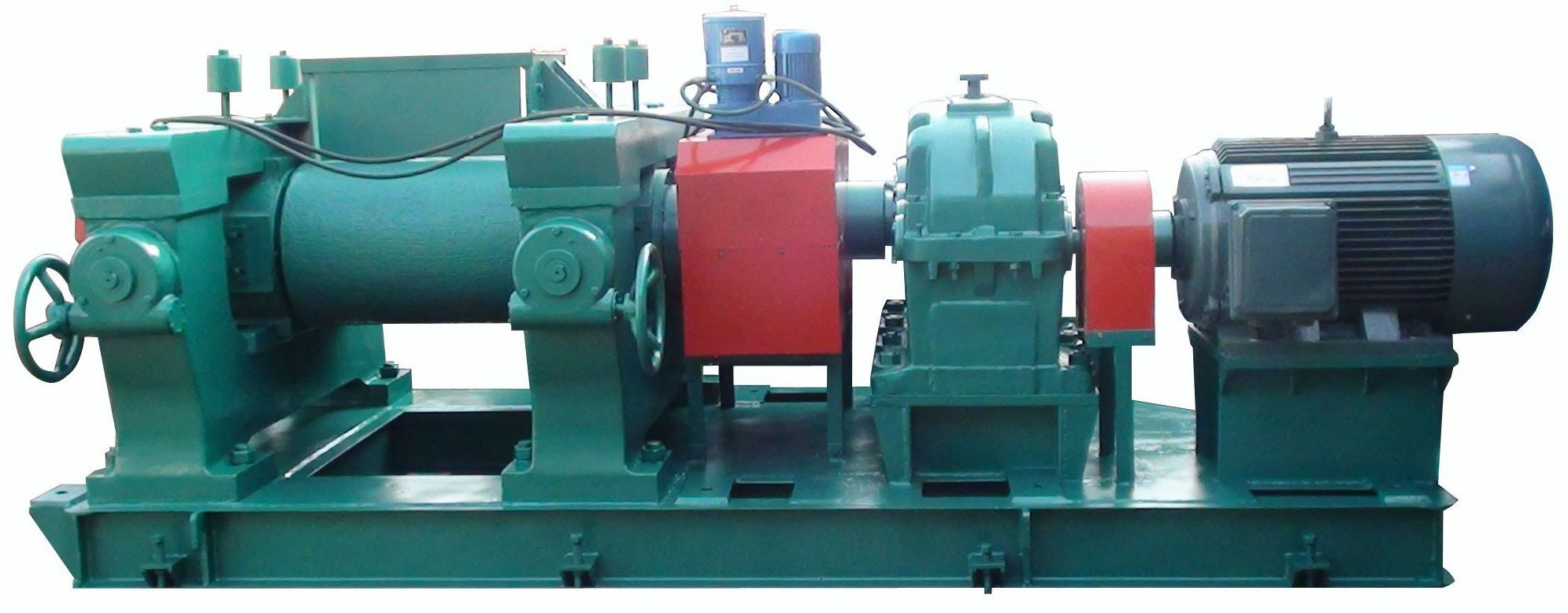

1. The roller of the rubber shredder is made of cast steel. The working face and shaft shoulder of the roller are repaired and welded with special wear-resistant welding materials to make the roller more durable. The roller of the rubber shredder is made of bearings, each roller has 6 bearings, which saves electricity and is easy to maintain.

2. Roller surface is precision machined by cylindrical grinder to ensure the coaxiality of roller and improve product quality;

3. Each tile box of the roller is equipped with a temperature measuring device, which is convenient to monitor the temperature of the roller and conducive to production operation;

4. The roller is equipped with labyrinth seal, which effectively prevents steel wire from entering the bearing chamber, prolongs the service life of the bearing, facilitates maintenance, and thus prolongs the life of the rubber breaker;

5. The tile box of the rubber shredder is made of cast steel, and the frame beam and the horse leg are welded with steel plate,which is better than the casting;

6. The base of the rubber shredder, the motor base and the reducer base are precision machined by the gantry milling machine to improve the accuracy and ensure the quality;

7. Reducer selection of bearing power, output shaft diameter of hard tooth surface cylindrical gear reducer, performance is better than oil field reducer.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

710

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

5600 x 2500 x 1750 mm

-

Year:

-

NEW

-

Weight (KG):

-

25000 kg

-

Power (kW):

-

280

-

Color:

-

Blue Green or customized

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YUQIAO Brand

-

Marketing Type:

-

Used Tire Recyling

-

Model Number:

-

710

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

5600 x 2500 x 1750 mm

-

Year:

-

NEW

-

Weight (KG):

-

25000 kg

-

Power (kW):

-

280

-

Color:

-

Blue Green or customized

Product Overview

710 Rubber shredder

1.Application:

It is mainly used for further crushing the coarse rubber rubber block, separating the steel wire and rubber, and finally getting about 10-30 mesh of rubber particles or rubber powder.

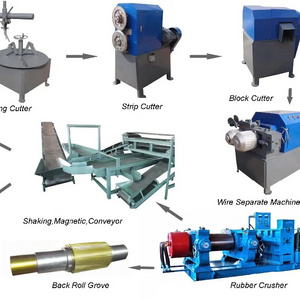

2. Equipment Composition:

It is mainly composed of cast-steel roller, cast steel tile box, cast-steel or welding frame, base, distance adjustment device,

safety gasket, lubrication system, transmission system, cooling device and electrical control system.

It is mainly used for further crushing the coarse rubber rubber block, separating the steel wire and rubber, and finally getting about 10-30 mesh of rubber particles or rubber powder.

2. Equipment Composition:

It is mainly composed of cast-steel roller, cast steel tile box, cast-steel or welding frame, base, distance adjustment device,

safety gasket, lubrication system, transmission system, cooling device and electrical control system.

FEATURES AT A GLANCE

Characteristic

:

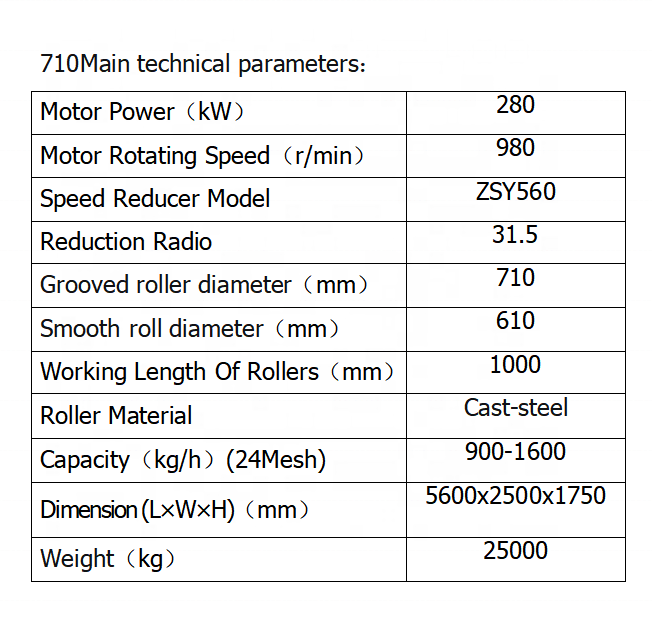

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Motor Power(kW)

|

280

|

|

2

|

Motor Rotating Speed(r/min)

|

980

|

|

3

|

Speed Reducer Model

|

ZSY560

|

|

4

|

Reduction Radio

|

31.5

|

|

5

|

Grooved roller diameter(mm)

|

710

|

|

6

|

Smooth roll diameter(mm)

|

610

|

|

7

|

Working Length Of Rollers(mm)

|

1000

|

|

8

|

Roller Material

|

Cast-steel

|

|

9

|

Capacity(kg/h)(24Mesh)

|

900-1600

|

|

10

|

Dimension (L×Wi×H)(mm)

|

5600ⅹ2500ⅹ1750mm

|

|

10

|

Weight(kg)

|

25000

|

PRODUCT CONFIGURATION

Grooved Roller

Smooth Roller

Japan Shimadzu hydraulic motor

Production Field

Successful Project

Project in Thailand

Project in India

Project in Russia

Recommend Products

SIMILAR PRODUCTS

Hot Searches