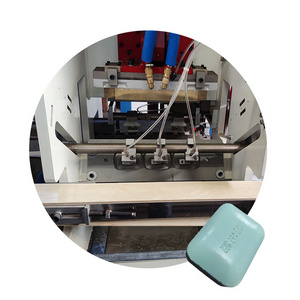

This stamper is feature by its simple structure, modular design, easy to be maintenanced. This machine uses best mechanical parts, such as two-speed gear reducer, speed variator and right-angle drive supplied by Rossi, Italy; coupling and shrinking sleeve by German manulacturer, bearings by SKFSweden; Guide rail by THK, Japan; electric parts by Siemens, Germany The feeding of soap bllt is perormed by a pilter, while the stamping and 60 degree rotating is completed by another slitter. The stamper is a mechatronic product. The control is realized by a PLC It controls the vacuum and compressed air on/off during stamping.

- Product Details

- {{item.text}}

Quick Details

-

name:

-

soap stamping machine

-

speed:

-

30-45 strokes /min

-

soap weight:

-

10-250g

-

Function:

-

press any soap shape

-

Mould:

-

6-8pcs per set

-

soap shape:

-

any shape

-

packing:

-

wooden case

-

Raw Material:

-

Srainless Steel

-

Power supply:

-

380 V 50Hz 3-phase

-

Compressed air pressure:

-

1 MPa.

Quick Details

-

Place of Origin:

-

Gansu, China

-

Brand Name:

-

LIMA

-

Weight (KG):

-

1500

-

name:

-

soap stamping machine

-

speed:

-

30-45 strokes /min

-

soap weight:

-

10-250g

-

Function:

-

press any soap shape

-

Mould:

-

6-8pcs per set

-

soap shape:

-

any shape

-

packing:

-

wooden case

-

Raw Material:

-

Srainless Steel

-

Power supply:

-

380 V 50Hz 3-phase

-

Compressed air pressure:

-

1 MPa.

Automatic toilet soap stamping machine for soap making machine

Product Description

Specification

|

item

|

Soap making production line

|

|

Warranty of core components

|

5 Years

|

|

Core Components

|

PLC, Engine, Gearbox, Motor

|

|

Key Selling Points

|

Easy to Operate

|

|

Advantage

|

High quality

|

|

Application

|

Soap Logo Stamping,Soap Cutting,Soap Packing

|

|

Capacity

|

5 to 45 strokes/minute.

|

|

PACKING

|

Wooden Case

|

|

Keywords

|

Soap Maker

|

Capacity:

6 pieces in one stroke, 5 to 45 strokes per minute.

Compressed air pressure: 1 MPa.

Fabrication:

The fabrication is in conformity with CE standard, passes BV certification. The control system meets C3 requirements;

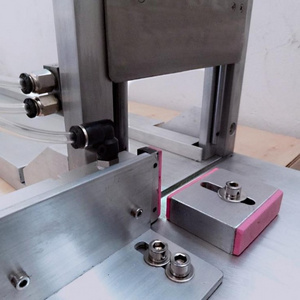

Mechanical design:

1. All parts in contact with soap are in stainless steel or aviation hard aluminum;

2. Complete with stamping die freezing system;

3. Vacuum pump and stamping die are excluded from the supply.

4.Two-speed gear reducer, speed variator and right angle drive are supplied by Rossi, Italy;

5. Professional splitters are supplied Guanhua, China;

6. Coupling and shrinking sleeve are by KTR, Germany;

7. The straight guide rail is by THK, Japan;

8. All pneumatic components by SMC, Japan;

9. Frequency changer and PLC by Siemens, Germany;

10. Angle encoder by Nemicon, Japan.

11. Manual lub pump is for stamper’s lubrication.

Electric:

All electric components are supplied by Schneider, France.

Total installed power: 5.5kW + 0.55 kW + 0.55 kW + 0.75 kW

Power supply: 380 V 50Hz 3-phase

Mechanical threaded fasteners:

All mechanical threaded fasteners, incl. bolts are metric having property class over 8.8, together with anti-loose parts.

6 pieces in one stroke, 5 to 45 strokes per minute.

Compressed air pressure: 1 MPa.

Fabrication:

The fabrication is in conformity with CE standard, passes BV certification. The control system meets C3 requirements;

Mechanical design:

1. All parts in contact with soap are in stainless steel or aviation hard aluminum;

2. Complete with stamping die freezing system;

3. Vacuum pump and stamping die are excluded from the supply.

4.Two-speed gear reducer, speed variator and right angle drive are supplied by Rossi, Italy;

5. Professional splitters are supplied Guanhua, China;

6. Coupling and shrinking sleeve are by KTR, Germany;

7. The straight guide rail is by THK, Japan;

8. All pneumatic components by SMC, Japan;

9. Frequency changer and PLC by Siemens, Germany;

10. Angle encoder by Nemicon, Japan.

11. Manual lub pump is for stamper’s lubrication.

Electric:

All electric components are supplied by Schneider, France.

Total installed power: 5.5kW + 0.55 kW + 0.55 kW + 0.75 kW

Power supply: 380 V 50Hz 3-phase

Mechanical threaded fasteners:

All mechanical threaded fasteners, incl. bolts are metric having property class over 8.8, together with anti-loose parts.

Details Images

Hot Searches