- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

38 kN

-

Theoretical Shot Volume(cm³):

-

200 cm³

-

Injection Rate (g/s):

-

103 g/s

-

Injection Weight (g):

-

180 g

-

Screw diameter (mm):

-

38 mm

-

Screw L/D Ratio:

-

22

-

Distance between Tie Bars:

-

425*375

-

Weight (KG):

-

3800 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

2000 mm

-

Model Number:

-

JM-120II

-

Brand Name:

-

fly

-

Power (kW):

-

15 kW

-

Product Name:

-

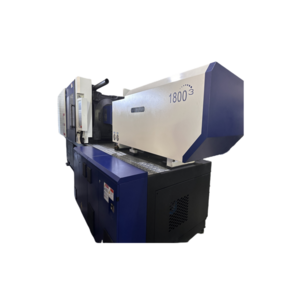

Plastic Injection Molding Machine

-

Application:

-

PLASTIC ITEMS PRODUCING

-

Color:

-

BLUE&WHITE

-

Shape:

-

CUBOID

-

Material:

-

STEEL

-

Characteristic:

-

CUSTOMER OEM

-

Size:

-

4.25x1.17x1.6m

-

intended for:

-

PLASTIC MANUFACTURERS

-

Quality:

-

high-quality

-

Service:

-

24-hour online

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

375mm

-

Distance between Tie Bars(Height)(mm):

-

425mm

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

38 kN

-

Theoretical Shot Volume(cm³):

-

200 cm³

-

Injection Rate (g/s):

-

103 g/s

-

Injection Weight (g):

-

180 g

-

Screw diameter (mm):

-

38 mm

-

Screw L/D Ratio:

-

22

-

Distance between Tie Bars:

-

425*375

-

Weight (KG):

-

3800 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

2000 mm

-

Model Number:

-

JM-120II

-

Brand Name:

-

fly

-

Power (kW):

-

15 kW

-

Product Name:

-

Plastic Injection Molding Machine

-

Application:

-

PLASTIC ITEMS PRODUCING

-

Color:

-

BLUE&WHITE

-

Shape:

-

CUBOID

-

Material:

-

STEEL

-

Characteristic:

-

CUSTOMER OEM

-

Size:

-

4.25x1.17x1.6m

-

intended for:

-

PLASTIC MANUFACTURERS

-

Quality:

-

high-quality

-

Service:

-

24-hour online

|

Product Name

|

|

Plastic Injection Molding Machine

|

|

|

|||

|

Application

|

|

Plastic Items Producing

|

|

|

|||

|

Color

|

|

Blue&White

|

|

|

|||

|

Shape

|

|

Cuboid

|

|

|

|||

|

Material

|

|

Steel

|

|

|

|||

|

Characteristic

|

|

Customer OEM

|

|

|

|||

|

Size

|

|

4.25x1.17x1.6M

|

|

|

|||

Product Display

Details Images

* Larger space between tie-bars, suitable for larger molds and multi-cavity necessary.

* Extended and widened guide support, higher repeat accuracy, stable movement, small deformation, greatly improve product quality and mold service life.

* Upgraded parts, Graphite-copper bushes and slider used on tie-bar,ejector and movable platen,ensure fast and precise mold close and open.

* Better designed mechanical structure and toggle system, faster cyde time, and improve production efficiency.

* European type ejector structure, larger space, convenient for maintenance.

* Prepared enough space for upgrade and retrofits.

* Built-in and adjustment free mechanical safety bar, more safe and convenient.

* Much higher rigidity mechanical system than normal Chinese lMM, not only improve machine's using-ife, but also can protect mold.

* Wide variety injection unit with modular design can be provided depending on the features of molded products.

* Full supported injection unit with dual precise linearguide rails,ensure the best precision and fast sartspeed.

* Dual carriage cylinders improve a better injectionprecision.

* Injection unit steel pipes adopt pipe fitting to connect, no welding design ensure maintenance and after-service to be easier.

* Mobile nozzle shield makes production and maintenance easier.

* Imported high quality SKD61 material screw tip, check ring and thrust ring; a lot kinds of screws design can meet different plastic material and special processing injection molding needs.

* Double layer insulated material barrel, effective heat insulation,prevent scald, safer production process.

* The high torque and high speed hydraulic motor is used in the preplasticated motor with high efficiency and high response.

* Roller slide structure to facilitate customers to change raw materials.

* Standard equipped with precise and energy saving servomotor system,energy saving capacity can reach to 20%-80% than traditional injection machine.

* World famous brands hydraulic parts ensure machine's reliability and fast response speed.

* Visible and dischargeable oil tank, easy for hydraulic circuit maintenance.

* Adopt modular adaptor valve blocks, hydraulic circuit and functions easy forup-grade and maintenance Effectively reduce pressure loss and improve responsiveness.

* Self-sealed magnetic suction filter, make your maintenance more convenient.

* Logical distribution of pump oil suction port, oil tank oil outlet and hydraulicpipe fits, easy for maintenance.

* Germany DIN standard hydraulic pipe fitting with seal, G screw thread styleplug, avoid oll pollution.

* World well-known brands electric parts.

* The high quality color liquid crystal controller, and the power system manufacturer cooperation research and development, thec ontrol is precise, the response speed is quicker, the powerfuls oftware control function, satisfies more different craft request.

Standard equipped LED three-color tower light with alarm, machine working situation is clear.

* Modernized network management function available.

* Water-proof rubber seal used on electric cabinet ensure high safety.

* Machine program according to CE safety standard.

Sample Display

Hot Searches