1. The product is controlled by a microcomputer, driven by hydraulic pressure, displayed with Chinese subtitles, and operated by man-machine dialogue.

2. Manual and semi-automatic operation modes can be selected arbitrarily, one-point foot switch has two functions of start and emergency stop.

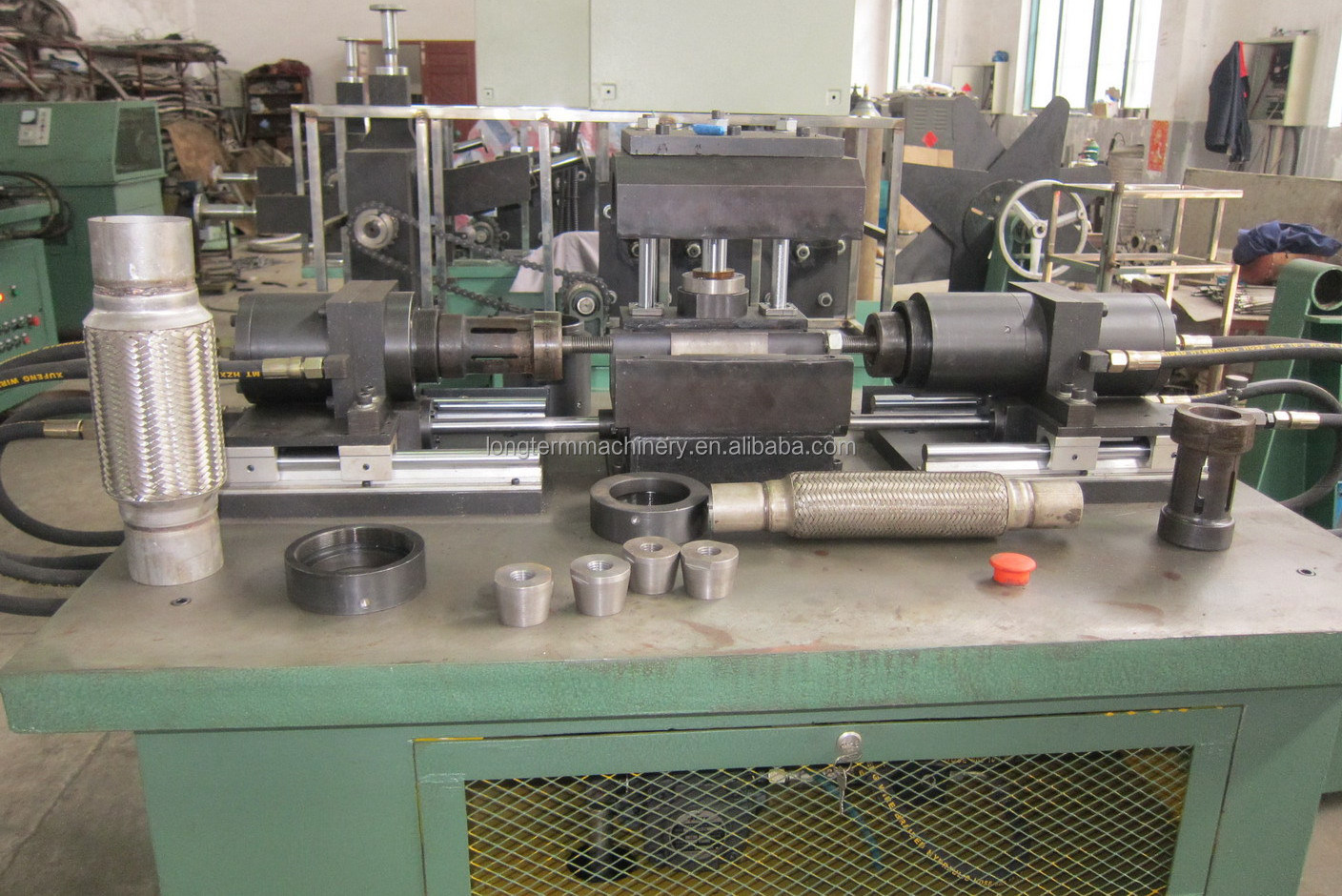

3. Single-station configuration, with straight line as the guide, good product repeatability as the carrier.

4. The whole machine has convenient operation, stable performance, high work efficiency, high safety factor, etc. It is an ideal equipment for the pipe fittings processing industry Shape: convex, concave, joint, long deviation, square, extension, oblique, V-shaped, elbow opening, flat elbow... etc., depending on the processed object to deform the mold shape.