- Product Details

- {{item.text}}

Quick Details

-

Roll Ratio(Front/Back):

-

1:1.25

-

Cooling Mode:

-

water colling

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Zotai

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

850*550*1100mm

-

Year:

-

Custom

-

Power (kW):

-

3

-

Weight (KG):

-

200 KG

-

Applicable Industries:

-

Rubber and Plastic Industry

-

Product name:

-

Lab Scale Two Roll Plastic and Rubber Mixing Mill

-

Roller diameter:

-

120mm

-

Roller length:

-

350mm

-

Heating method:

-

electric heating tube

-

Revolving ratio:

-

1:1.25

-

One time feeding:

-

≤ 1kg

-

Maximum roll distance:

-

5mm

-

Roller deceleration:

-

constant speed (adjustable speed can be set)

-

Power supply:

-

380V

-

Total weight:

-

About 200kg

Quick Details

-

Diameter of Roll(mm):

-

120 mm

-

Rotation Speed of Front Roll(rpm):

-

1 - 16 rpm

-

Length of Roll(mm):

-

350 mm

-

Roll Ratio(Front/Back):

-

1:1.25

-

Cooling Mode:

-

water colling

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Zotai

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

850*550*1100mm

-

Year:

-

Custom

-

Power (kW):

-

3

-

Weight (KG):

-

200 KG

-

Applicable Industries:

-

Rubber and Plastic Industry

-

Product name:

-

Lab Scale Two Roll Plastic and Rubber Mixing Mill

-

Roller diameter:

-

120mm

-

Roller length:

-

350mm

-

Heating method:

-

electric heating tube

-

Revolving ratio:

-

1:1.25

-

One time feeding:

-

≤ 1kg

-

Maximum roll distance:

-

5mm

-

Roller deceleration:

-

constant speed (adjustable speed can be set)

-

Power supply:

-

380V

-

Total weight:

-

About 200kg

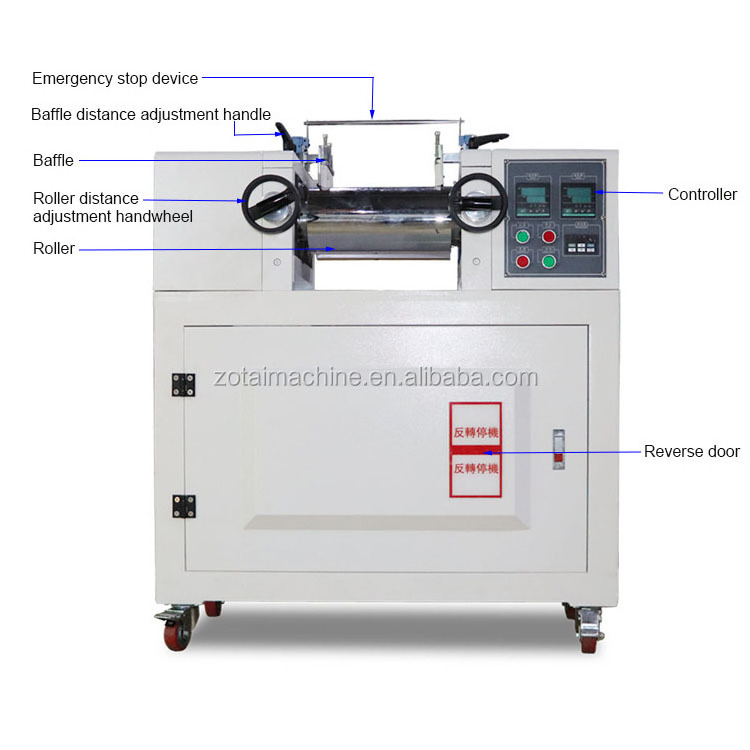

Lab Scale Two Roll Plastic and Rubber Mixing Mill

Technical parameters:

|

Roller diameter |

120mm |

|

Roller length |

350mm |

|

Front roller linear speed |

16r / min |

|

Roller speed ratio |

1:1.25 |

|

One time feeding |

≤ 1kg |

|

Main motor power |

0.75kw |

|

Roller deceleration |

constant speed (adjustable speed can be set) |

|

Reducer |

ZQ series with soft tooth surface |

|

Maximum roll distance |

5mm |

|

Power supply |

AC 380V |

|

Total weight |

About 200kg |

|

Machine size |

850 * 550 * 1100mm |

A pplication:

It is mainly used for mixing equipment of silica gel and rubber. It has the characteristics of fine structure, safety and convenience, wide applicability and high efficiency.

Introduction:

1. The machine is mainly composed of a body-shaped frame, frame, roller, transmission gear, gear reducer, motor and other parts. The roller is made of chilled cast iron. The surface of workpiece is grinded and has high hardness and wear resistance. The roller is hollow and filled with water but water system. The worm gear reducer is installed next to the base, and the roller and frame are arranged on the upper part of the machine to make it compact. Easy to operate

2. The transmission part of the machine is driven by the motor of the hard tooth surface reducer set outside the frame. The rear roller is driven to rotate by the transmission gear, and then the front roller is driven by a pair of speed ratio gears installed at the left end of the roller to make the front and rear rollers rotate at different speeds in relative directions.

3. The transmission gear is equipped with closed protection device, and the machine is equipped with electric braking device. When emergency stop is required, press the emergency stop switch to brake immediately, which makes the safety performance more reliable.

We can produce all kinds of Rubber Test Machines:

1. Zotai Service:

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide operation video for machines .

2. Onsite Service:

A. Device installation;

B. Equipment Operation Test Technology training;

C. Equipment Calibration;

D. Daily maintenance and maintenance of equipment

3. Free technical training for visiting factories

4. 24-hour Online contact

5. Free software upgrades

6. Free information:

A.Product Instruction;

B.Product operation instruction/video;

C.Experiment Test (test application, test report)

7. Device Problem Handling:

A. Social media 24 hours online communication;

B. Mail Seamless Docking;

C. Video Conferencing;

D. Artificial free door-to-door service