Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

400 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haisi

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

132

-

Weight:

-

4000

-

Automatic Grade:

-

automatic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Usage:

-

plastic compounding granulation

-

Motor Brand:

-

Simens or WNM

-

Inverter Brand:

-

ABB

-

Screw material:

-

Bimetallic

-

Color:

-

Customizable

-

Motor pole:

-

four-pole motor

-

Visit and machine test service:

-

yes

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

44

-

Screw diameter (mm):

-

71 mm

-

Screw Speed (rpm):

-

400 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haisi

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

132

-

Weight:

-

4000

-

Automatic Grade:

-

automatic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Usage:

-

plastic compounding granulation

-

Motor Brand:

-

Simens or WNM

-

Inverter Brand:

-

ABB

-

Screw material:

-

Bimetallic

-

Color:

-

Customizable

-

Motor pole:

-

four-pole motor

-

Visit and machine test service:

-

yes

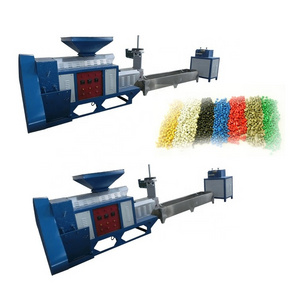

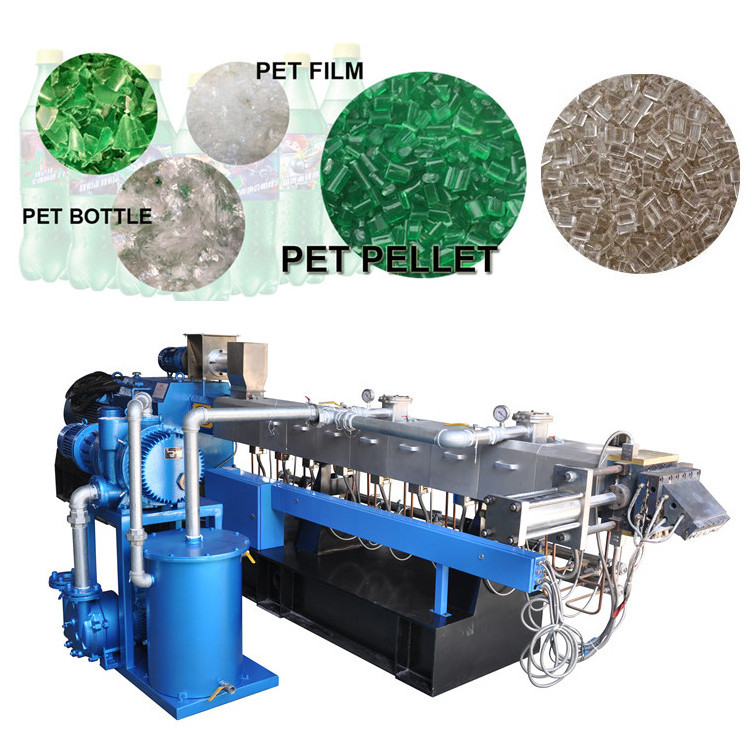

Waste Plastic Recycling Extruder /PET Extrusion Machine/Pellets Making Machine With Best Price

Advantages of plastic recycling twin screw extruder compared with single screw extruder

High er production capacity.

Energy and time savings as pre-drying and crystallization are omitted .

H igh quality of the end product which does not become yellowish .

High flexibility because formula and colors can be changed very quickly due to the good self-cleaning behavior of the plastic recycling twin screw extruder .

Much simpler logistics because pelletized new product and different regenerates can be processed together.

Application

Most recycling tasks make granules as a mediate product. For some materials, either pelletizing system or sheet extrusion downstream can be equipped after the plastic recycling twin screw extruder. In the case of PET bottle flakes recycling it can produce PET pellets and it can make PET sheet directly. This is a branch of our direct extrusion technology!

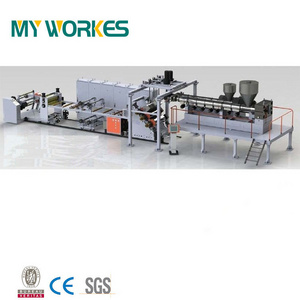

Auxiliary machines you may need:

The

plastic recycling twin screw extruder

line with belt conveyer,

crusher,

extruder,

auxiliary equipment. The line with characteristics of high output,

low energy dissipation,

labor-force saving,

and high quality pellets,

is an ideal equipment

for

plastic recycling twin screw extruder

.

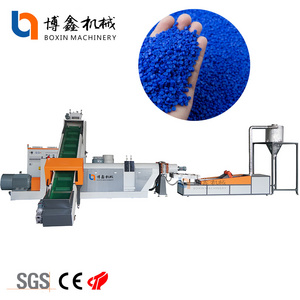

Plastic recycling twin screw extruder process

According to the cleanliness of raw materials and actual production needs, plastic recycling twin screw extruder with water ring pelletizing or strand pelletizing can be selected to match different raw materials.

1. PET raw material feeding

2. TSE series plastic recycling twin screw extruder

3. Degassing

4. Roots pump and special designed filter

5. Special designed water bath

6. Air blower

7. Strand pelletizer

Compared with other types of vacuum pumps, roots vacuum pump has the following advantages:

1) There is no gas compression in the pump chamber, and there is a gap between moving parts, so it is not sensitive to dust and steam in the pumped gas, so condensable steam can be extracted.

2) The moving parts in the pump chamber do not need oil lubrication, which can avoid the pollution of oil steam to the vacuum system and is conducive to obtaining oil-free vacuum.

3) The utility model has the advantages of simple structure, low noise, no contact between moving parts in the pump cavity, no damage and low maintenance cost.

4) start quickly and reach the limit vacuum in a short time.

Technical Data:

|

Mode |

Diameter (mm) |

L/D |

speed (r/min) |

Motor power (kw) |

Torque (N.m) |

Capacity (kg/h) |

|

TSE-65B |

62.4 | 32-64 | 600 | 90 | 716 | 250-360 |

|

TSH-65B |

62.4 | 32-64 | 600-800 | 110-160 | 875 | 350-500 |

|

TSE-75B |

71 | 32-64 | 600 | 132 | 1050 | 350-500 |

|

TS H -75 B |

71 | 32-64 | 600-800 | 200-250 | 1365 | 600-800 |

|

TSE-95B |

93 | 32-64 | 600 | 315 | 2560 | 800-1200 |

|

TSH-95B |

93 | 32-64 | 600-800 | 400-450 | 2506 | 1200-1600 |

1.gearbox:

New-style project of parallel three-axises driving makes the convey axis,convey chain,decelerate and the torque assignment get together,which keeo it compact,and the key bearings are imported.

The select material of drive components is dainty. Including super intension alloy cementiteing steel,cementiting and quenching ,gear grinding technics ,strengthening of tooth face.So they can ensure high torque,high precision and low noise.

Soakage and coerce lubrication integrate smoothly.When the hydraulic circuit is over pressed, it alarms.

2. feeding system:

Metering feeders are equipped with single screw,twin screw,hollow screw,forced-feeding,side feeding,liquid-adding system,etc

3.Screw and The barrel

The screw elements and then kneading blocks are designed accurately,by precise processed, agile combination,with interchangeability, which can fulfill efficient self-cleaning,transmission,compounding,pressure-forming.

The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat-treament.

Euro-style rectangle barrel,reflux refrigeration is optimized and disposed,which makes temperature difference in C areas smaller

According to the material and special techinics demands,the material of cylinder can use high quality nitrided steel,corrosion proof or antifriction with corresponding process

4.die head

the die head have two types :manual whirling and hydrulic pressure screen changer.

Changing screen is easy and finishes within few minutes.

5.electric control system

adopting imported PLC(OMRON or SIMES) to achieve optimized process control.Stronger function,steady performance and much higher accuracy. it can be also accomplished full-set link-lock protection,trouble safeguard,fault alarm cluing and so on

operation interface on touching screen is visual and marked ,which is brief and easy to use

7.Pelletizing line

Variou modes of pelletizing,such as water-cooling strand,air-cooling pelletizing,water-ring pelletizing,under water pelleting,etc.