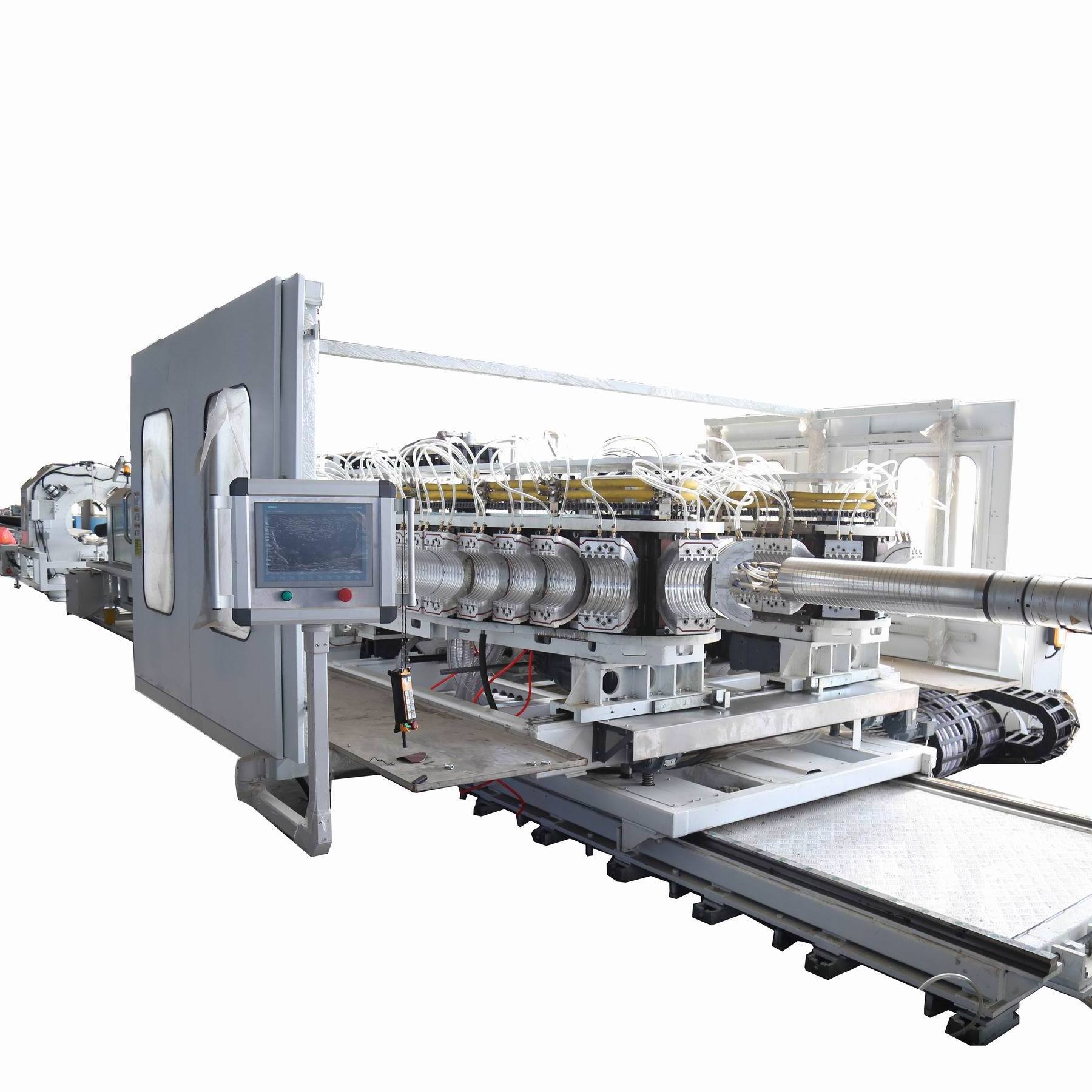

1)Material:High-quality Alloy Steel

2)Nitriding Treatment

3)With the adjustment of pads, wall thickness adjustable.

4)Combined nose, reasonable structure, uniform distribution of flow channel, to

ensure a smooth extrusion.

5)Stereotyped use of high-quality stainless steel water jacket materials, materials, through a complicated shape, and cold roll

annealing process to ensure the processing performance and physical performance.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Weifang

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

35000mm x 4000mm x 3800mm

-

Power (kW):

-

260

-

Weight:

-

20000KG

-

Production of pipe material range:

-

OD40-180

-

Maximum capacity of the production line:

-

9 ton / day

-

Use resin:

-

HDPE80,PE100

-

Auto loader:

-

1 set

-

SJ65/33 Single-Screw Extruder:

-

1 set

-

SJ75/33 Single-Screw Extruder:

-

1 set

-

Forming machine:

-

1 set

-

Water tank:

-

1 set

-

Cutting machine:

-

1 set

-

Auto-Stacker machine:

-

1 set

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

Brazil, Pakistan, Mexico, Thailand, Malaysia, Morocco, Kenya, Argentina, Chile, UAE, Colombia, Algeria, Sri Lanka, Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan

-

Marketing Type:

-

Ordinary Product

-

Certification:

-

CE ISO

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

China

-

Brand Name:

-

Weifang

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

35000mm x 4000mm x 3800mm

-

Power (kW):

-

260

-

Weight:

-

20000KG

-

Production of pipe material range:

-

OD40-180

-

Maximum capacity of the production line:

-

9 ton / day

-

Use resin:

-

HDPE80,PE100

-

Auto loader:

-

1 set

-

SJ65/33 Single-Screw Extruder:

-

1 set

-

SJ75/33 Single-Screw Extruder:

-

1 set

-

Forming machine:

-

1 set

-

Water tank:

-

1 set

-

Cutting machine:

-

1 set

-

Auto-Stacker machine:

-

1 set

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

Brazil, Pakistan, Mexico, Thailand, Malaysia, Morocco, Kenya, Argentina, Chile, UAE, Colombia, Algeria, Sri Lanka, Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan

-

Marketing Type:

-

Ordinary Product

-

Certification:

-

CE ISO

Product Description

Specification

|

item

|

value

|

|

Application

|

Wire, PIPE

|

|

Plastic Processed

|

PE, PP, FRPP/PVC, PE/PP

|

|

Condition

|

New

|

|

Screw Design

|

Single-screw

|

|

Screw Material

|

38CrMoALA

|

|

Screw diameter (mm)

|

65

|

|

Screw L/D Ratio

|

33:1

|

|

Screw Speed (rpm)

|

35rpm

|

|

Showroom Location

|

Philippines, Brazil, Pakistan, Mexico, Thailand, Morocco, Argentina, Chile, Algeria, Sri Lanka, Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan

|

|

Place of Origin

|

China

|

|

Brand Name

|

Weifang

|

|

Voltage

|

Customized

|

|

Dimension(L*W*H)

|

35000mm x 4000mm x 3800mm

|

|

Power (kW)

|

260

|

|

Weight

|

20000KG

|

|

Certification

|

CE ISO

|

|

Warranty

|

1 Year

|

|

|

Video technical support, Free spare parts, Online support

|

|

Key Selling Points

|

High Productivity

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts

|

|

Local Service Location

|

Brazil, Pakistan, Mexico, Thailand, Malaysia, Morocco, Kenya, Argentina, Chile, UAE, Colombia, Algeria, Sri Lanka, Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Construction works

|

|

Marketing Type

|

Ordinary Product

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Warranty of core components

|

1.5 years

|

|

Core Components

|

Motor, Gear, PLC

|

|

Production of pipe material range

|

OD40-180

|

|

Maximum capacity of the production line

|

9 ton / day

|

|

Use resin

|

HDPE80,PE100

|

|

Auto loader

|

1 set

|

|

SJ65/33 Single-Screw Extruder

|

1 set

|

|

SJ75/33 Single-Screw Extruder

|

1 set

|

|

Forming machine

|

1 set

|

|

Water tank

|

1 set

|

|

Cutting machine

|

1 set

|

|

Auto-Stacker machine

|

1 set

|

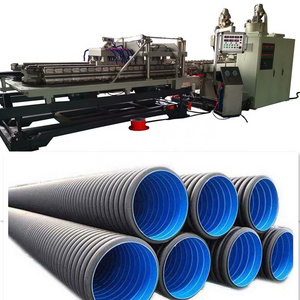

Die head

Aluminum Forming mould

Forming Mould made of mechanical and physical properties of cast aluminum alloy material with high fatigue resistance, abrasion

resistance and strength

resistance and strength

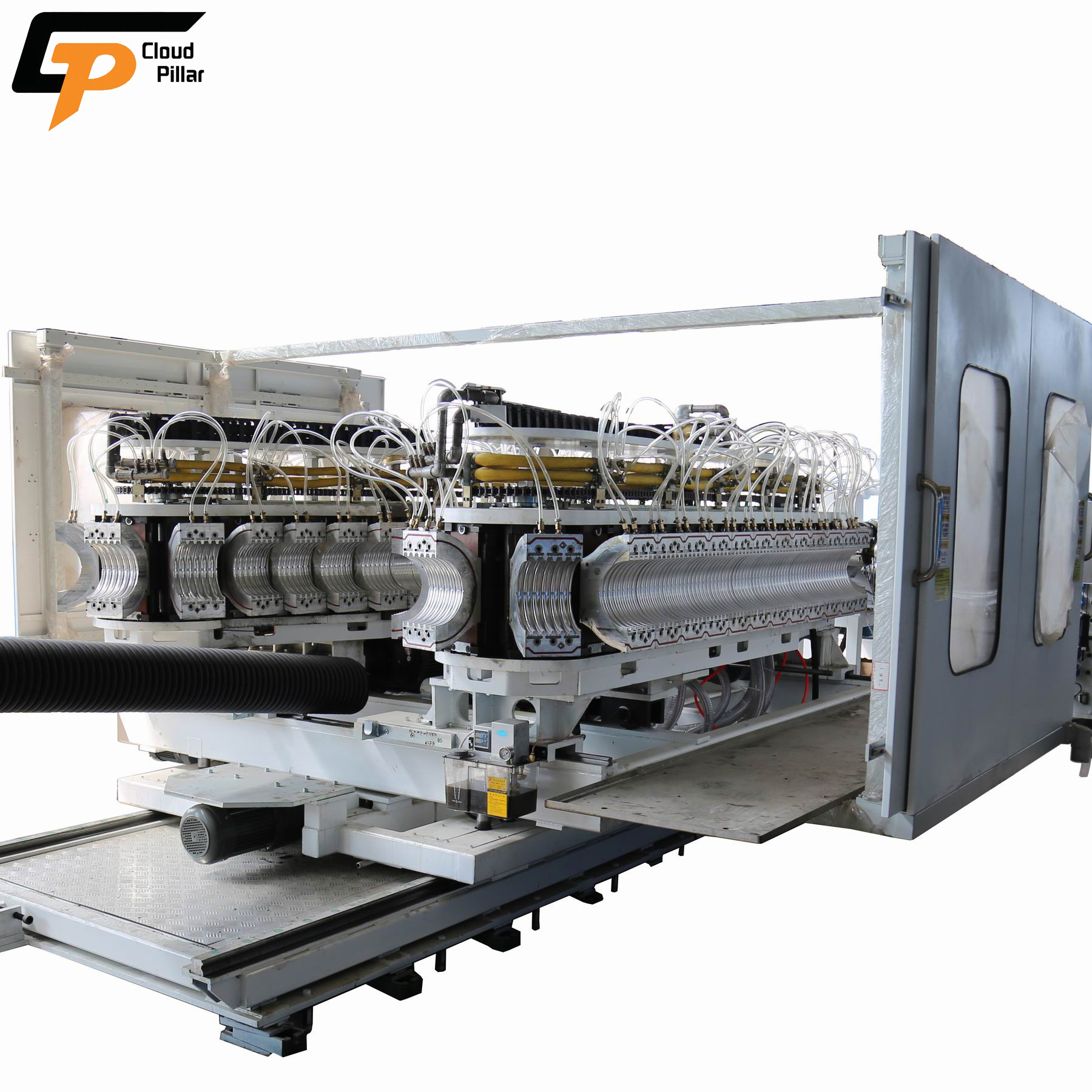

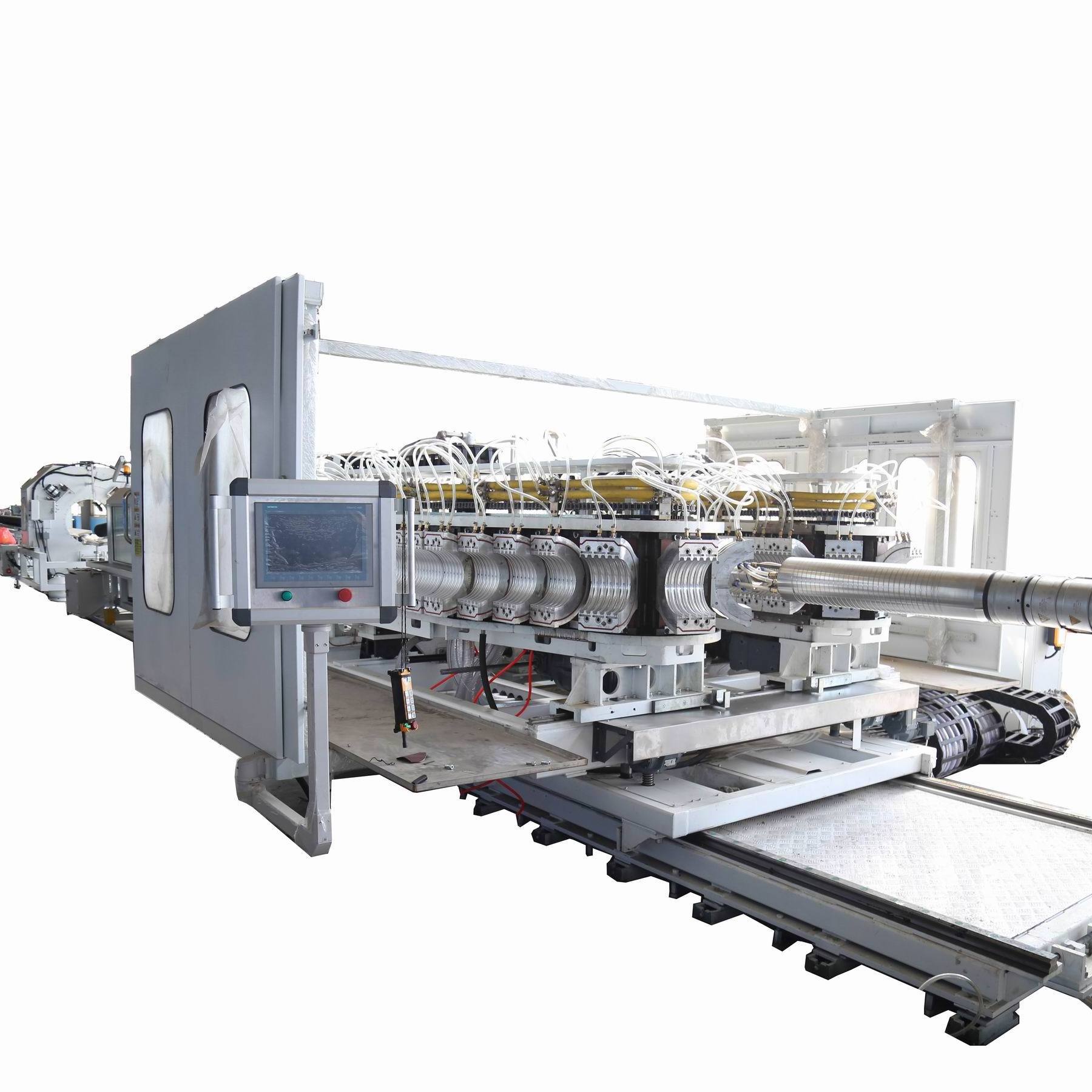

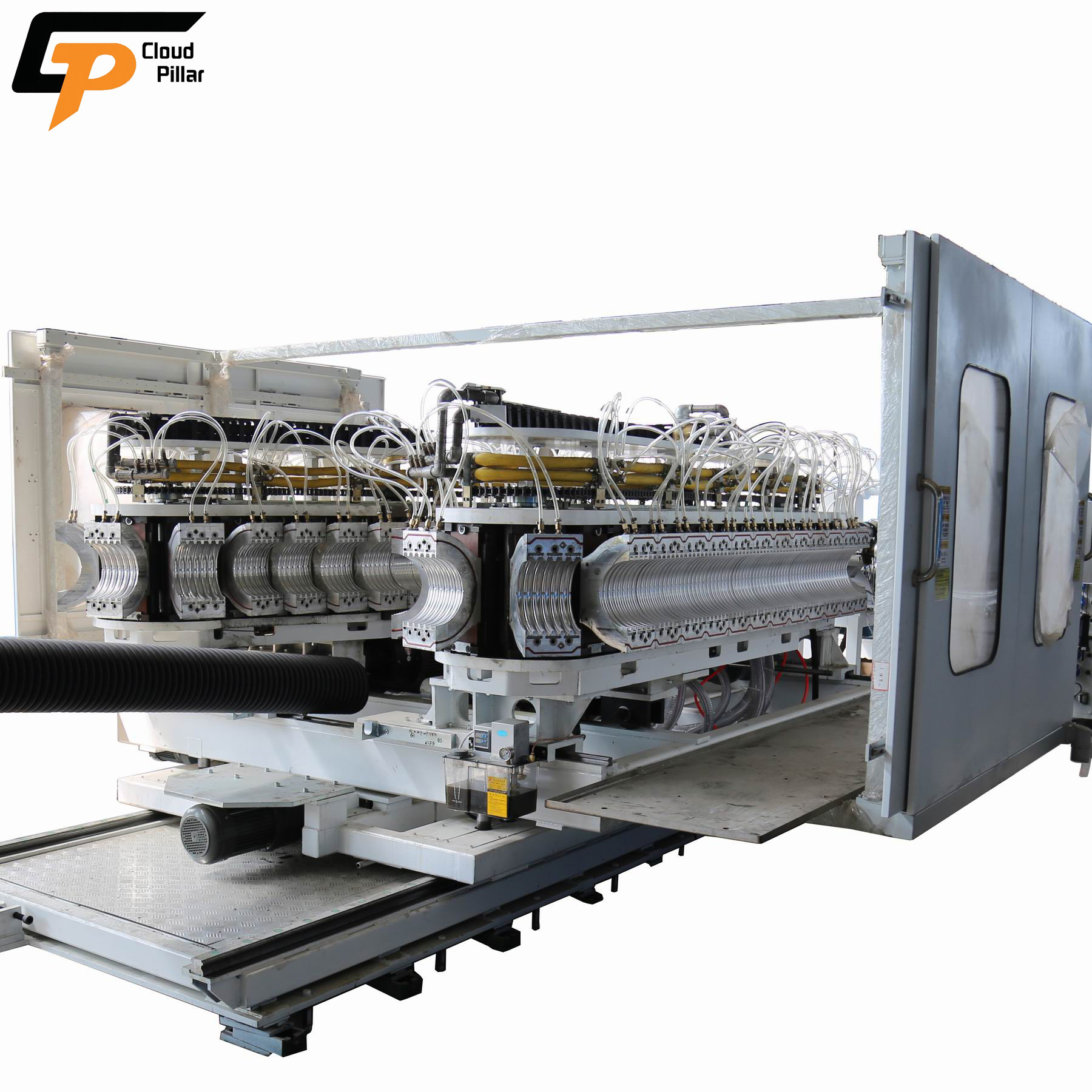

High speed Forming machine

Our Advantages: our corrugator(forming machine) is high speed design,speed can get 2.8-4m/min.Corrugated moulding machine with a

new horizontal structure layout, compared with the vertical structure layout, the machine is more riglower center of gravity,

running more smoothly, more convenient for operation and maintenance

new horizontal structure layout, compared with the vertical structure layout, the machine is more riglower center of gravity,

running more smoothly, more convenient for operation and maintenance

Water tank

1) The cooling water tank adopts double-sided side-opening structure, which is easy to operate and maintain

2) Tank materials: stainless steel

2) Tank materials: stainless steel

Saw dust cutting machine

1) No chip cutting, hydraulic feeding mechanism, high precision, ensure smooth section

2) Clamping mode: pneumatic clamping;

3) The PLC control system is controlled and equipped with standard communication interface to facilitate the connection with

compatible devices

2) Clamping mode: pneumatic clamping;

3) The PLC control system is controlled and equipped with standard communication interface to facilitate the connection with

compatible devices

Auto Stackor Machine

1) The height of the feeding rack is adjusted by electric power, which is convenient to operate

2) Equipped with thoughtful protective devices to ensure the safety of the production site.

2) Equipped with thoughtful protective devices to ensure the safety of the production site.

Packing & Delivery

Take the tractor tires off and drive into the container

3 units in a 40' container

Hot Searches