- Product Details

- {{item.text}}

Quick Details

-

Production Process:

-

casting steel ball

-

Business Position:

-

Manufacturer

-

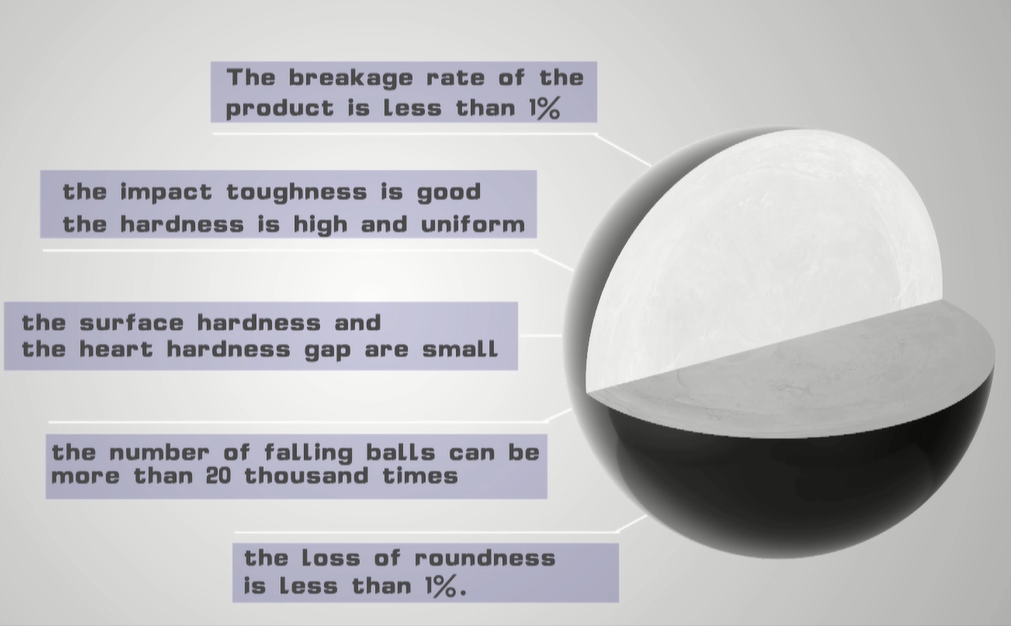

Hardness:

-

45-67HRC

-

Breakage Rate:

-

Dia.17mm-Dia.80mm:0.5%max Dia.90-Dia.130mm:1%max

-

drop times:

-

≥12000times

-

Microstructure:

-

M+C

-

Impact Value:

-

1-7J/CM2 min

-

Certification:

-

ISO9001:2015

-

Heat treatment:

-

Quenching Hardening

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HF

-

Model Number:

-

Dia.17mm-Dia.150mm

-

Production Process:

-

casting steel ball

-

Business Position:

-

Manufacturer

-

Hardness:

-

45-67HRC

-

Breakage Rate:

-

Dia.17mm-Dia.80mm:0.5%max Dia.90-Dia.130mm:1%max

-

drop times:

-

≥12000times

-

Microstructure:

-

M+C

-

Impact Value:

-

1-7J/CM2 min

-

Certification:

-

ISO9001:2015

-

Heat treatment:

-

Quenching Hardening

high hardness quality medium low price chrome die alloy cast casting grinding steel iron ball for sale cement mining ball mill

1.Diameter tolerance and Length tolerance

|

Diameter(mm)

|

Φ<30 |

30<Φ<60 |

60<Φ<80 |

80<Φ<100 |

Φ>100 |

|

Diameter tolerance(mm) |

+1,-1 |

+1.5,-1 |

+2,-1 |

+2.5,-1 |

+3,-1 |

2.Chemical composition

|

Name |

Brand

|

Chemical composition(%) |

||||||||

|

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

Ni |

P |

S |

|

|

Chrome alloy casting iron ball

|

ZQCr26 |

2.0-3.3 |

1.2max |

0.3-1.5 |

>23.0-30.0 |

0-3.0 |

0-1.2 |

0-1.5 |

≤0.10 |

≤0.06 |

|

ZQCr20 |

2.0-3.3 |

1.2max |

0.3-1.5 |

>18.0-23.0 |

0-3.0 |

0-1.2 |

0-1.5 |

≤0.10 |

≤0.06 |

|

|

ZQCr15 |

2.0-3.3 |

1.2max |

0.3-1.5 |

>14.0-18.0 |

0-3.0 |

0-1.2 |

0-1.5 |

≤0.10 |

≤0.06 |

|

|

ZQCr12 |

2.0-3.3 |

1.2max |

0.3-1.5 |

>10.0-14.0 |

0-3.0 |

0-1.2 |

0-1.5 |

≤0.10 |

≤0.06 |

|

|

ZQCr8 |

2.1-3.3 |

2.2max |

0.3-1.5 |

7.0-10.0 |

0-1.0 |

0-0.8 |

- |

≤0.10 |

≤0.06 |

|

|

ZQCr5 |

2.1-3.3 |

1.5max |

0.3-1.5 |

4.0-6.0 |

0-1.0 |

0-0.8 |

- |

≤0.10 |

≤0.10 |

|

|

ZQCr2 |

2.1-3.6 |

1.5max |

0.3-1.5 |

1.0-3.0 |

0-1.0 |

0-0.8 |

- |

≤0.10 |

≤0.10 |

|

3.Technical specification

|

Name |

Brand |

(mm) Diameter |

(HRC) Hardness |

Breakage rate |

(J/cm²) Impact value |

Drop times |

Micro structure |

|

Chrome alloy casting iron ball

|

ZQCr26 |

17-150 |

>58 |

<1% |

>7 |

≥12000 |

M+C |

|

ZQCr20 |

17-150 |

>58 |

<1% |

>6 |

≥12000 |

M+C |

|

|

ZQCr15 |

17-150 |

>58 |

<1% |

>5 |

≥12000 |

M+C |

|

|

ZQCr12 |

17-150 |

>58 |

<1% |

>3.5 |

≥12000 |

M+C |

|

|

ZQCr8 |

17-150 |

>55 |

<1% |

>3 |

≥12000 |

M+C |

|

|

ZQCr5 |

17-150 |

>47 |

<1% |

>2 |

≥10000 |

M+C |

|

|

ZQCr2 |

17-150 |

>45 |

<1% |

>1.5 |

≥8000 |

P+C |

Production process of Chrome alloy casting iron ball

Raw material→Secientic proportioning→Electric furnace smelting→Assay before furnace→Mould forming→Polishing→Heat treatment→Packing

| Packaging | Diameter | Weight |

| Bag | 17-150mm | 1000kg/bag |

| Drum | 15-20mm | 1000kg/drum |

| 25-30mm | 950kg/drum | |

| 40-60mm | 900kg/drum | |

| 70-100mm | 850kg/drum | |

| 110-150mm | 800kg/drum | |

| Container | 17-150mm | 25tons |