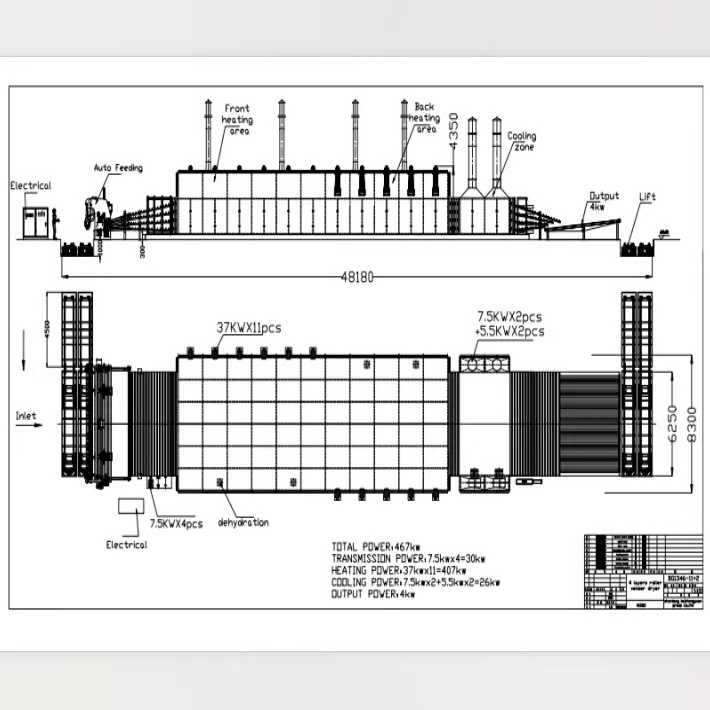

High-quality Cold-rolled Sheet Steel Spray Box

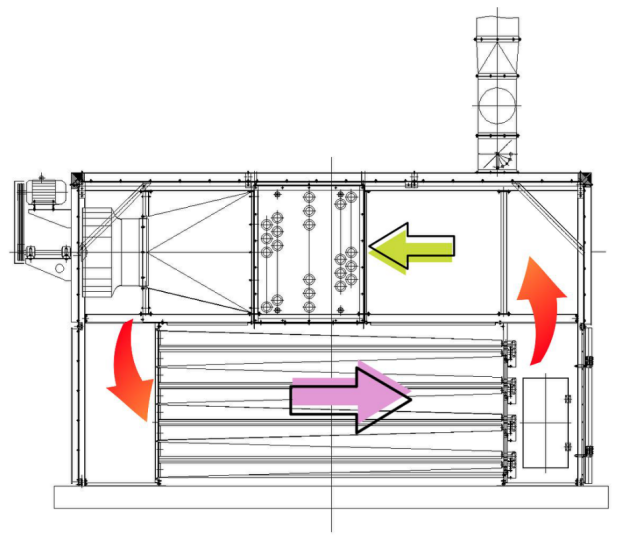

Germany Designed Hot Air Blower

Simple Contorl

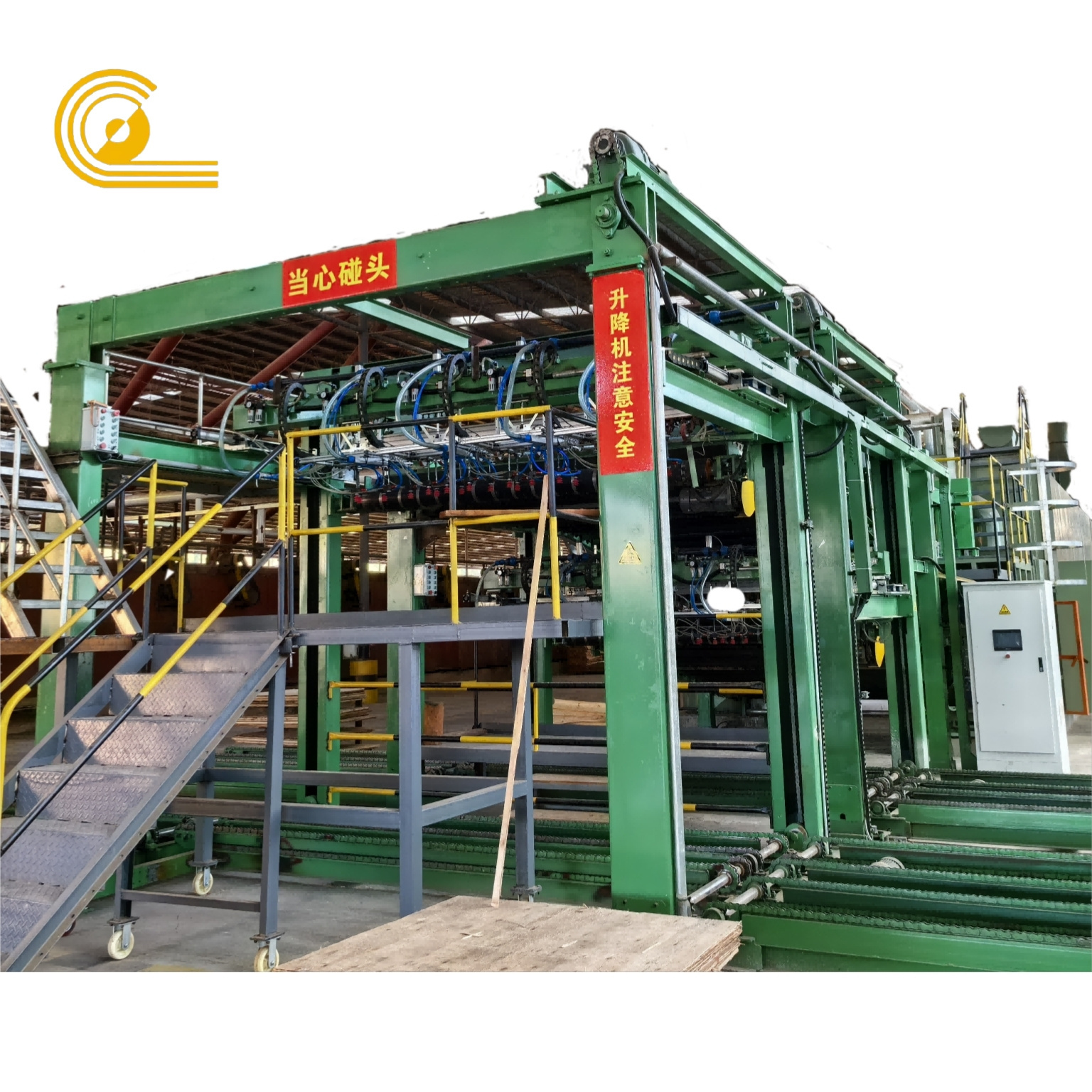

Fully Automatic Plate Feeding

Low-resistance Efficient Heating system

Device Extended working width