- Product Details

- {{item.text}}

Quick Details

-

Cabinet inner worksize::

-

Diameter 400mm*Length 650mm

-

Impeller head power:

-

4.0KW

-

Dust separation system fan motor:

-

1.5KW

-

Shot lifting system:

-

0.75kw

-

Roller belt drive motor:

-

0.75KW

-

Voltage::

-

380V 50HZ

-

Abrasive flow rate::

-

60kg/min

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

300 KG

-

Product name:

-

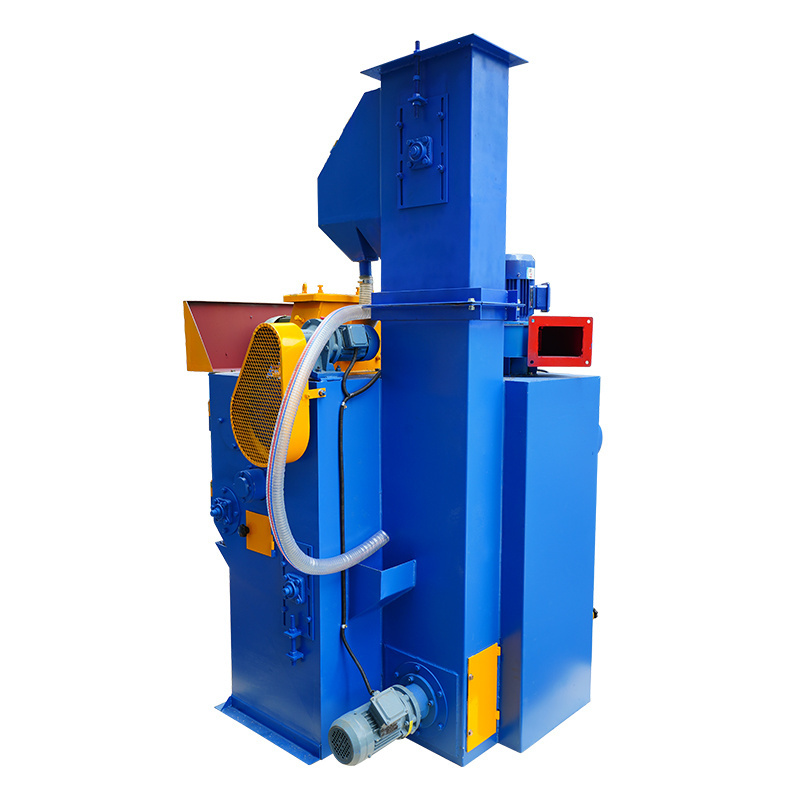

Tumble Belt Shot Blasting Machine

-

Cabinet inner worksize::

-

Diameter 400mm*Length 650mm

-

Impeller head power:

-

4.0KW

-

Dust separation system fan motor:

-

1.5KW

-

Shot lifting system:

-

0.75kw

-

Roller belt drive motor:

-

0.75KW

-

Voltage::

-

380V 50HZ

-

Abrasive flow rate::

-

60kg/min

Product Description

Automatic tumble belt shot blasting machine airless steel shot blaster

The tumble belt shot blasting machine is suitable for surface cleaning and strengthening of medium or small size castings, forge pieces and a variety of hardware.

Tumble belt shot blasting clean-up machine has advantages of advanced design, rational construction, low-power.

It is for different production capacity, the machine can be used not only as a single machine, but also as a part of a line.

The

working principle

of the shot blasting machine: the shot blasting machine is not powered by compressed air, but is powered by an electromechanical shot blasting machine, and uses the high-speed projectile thrown by the shot blasting machine to clean or strengthen the surface of the metal workpiece.

Application

The tumble belt shot blasting machines are used for surface cleaning of cast, pressed, heat treated, forged, etc. products without sharp corners and suitable for rounding. Ability to sandblast small and medium sized parts is the significant advantage.

Product Details

Automatic Tumble belt shot blasting machine features

1.S

hot blasting machine adopts a double-disc direct-connected type, motor bearing has long service life and good stability;

2. The dust removal system is equipped with a pulse filter cartridge for dust removal, which has high dust removal efficiency and convenient installation and maintenance;

3. The shot blasting chamber adopts section steel and plate riveted welding structure, with reasonable structure, high strength and good rigidity;

4. The wear-resistant alloy guard plate is laid in the shot blasting chamber, which is wear-resistant, impact-resistant and has a long service life;

5. Prevent projectiles from flying out; make a 2.5m long sub-chamber body at the inlet and outlet, and set up a dust-proof baffle by a combination of hanging leather and spring rubber plate with an interval of 600mm in the sub-chamber to ensure that dust and steel shot will not pop out;

6. The equipment work adopts manual control, which is convenient and quick;

7. The equipment is equipped with safety protection devices to ensure safe and effective work.

Specification

|

Model

|

KF-S4065

|

|

Cabinet inner worksize:

|

Diameter 400mm * Length 650mm

|

|

Impeller type:

|

Double-disc

|

|

Impeller head power:

|

4.0KW

|

|

Roller belt drive motor:

|

0.75KW

|

|

Dust removal system fan motor:

|

1.5KW

|

|

Shot lifting system:

|

0.75KW

|

|

Abrasive flow rate:

|

60kg/min

|

|

Voltage:

|

380V 50HZ

|

Related Products

Product Packaging

All our machines comply with international export standards and are available in wooden boxes and foam films

Hot Searches