Step1

: set the parameters we need on HMI

Step2

: pour bulk products into the storage hopper manually or automatically

Step3

: multifunction weighing dosing machine will dose target weight we need

Step4

: put bags into bag magazine

Step5

: zipper device open the ziplock

Step6

: positioning bags to the filling station

Step7

: bag open and sending out “request filling” signal

Step8

: filling machine drop down products with target weight into open bags

Step9

: the sealing jaws seal bags automatically

- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

6-16bags/min

-

Weight (KG):

-

450

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Top Y

-

Dimension(L*W*H):

-

195*65*150cm

Quick Details

-

Function:

-

FILLING, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Pouch

-

Packaging Material:

-

Plastic

-

Production Capacity:

-

6-16bags/min

-

Weight (KG):

-

450

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Top Y

-

Dimension(L*W*H):

-

195*65*150cm

Products Description

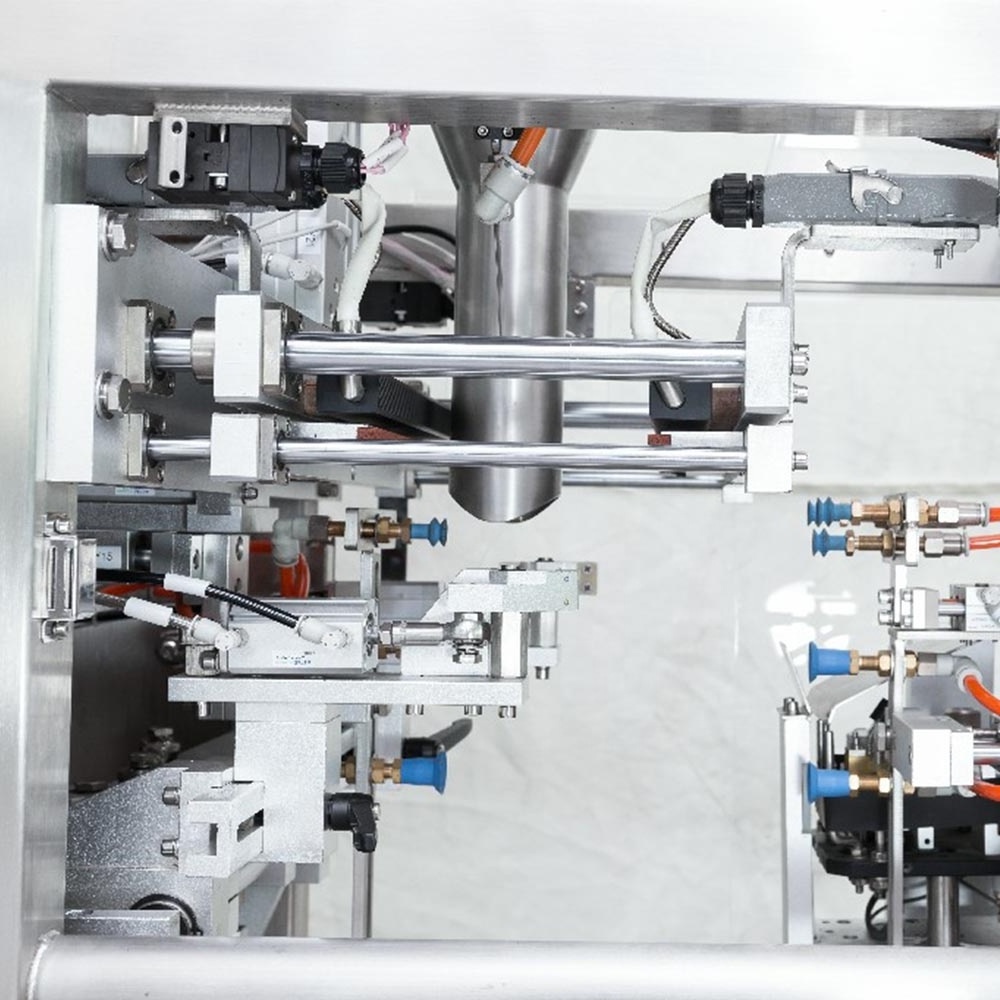

Mini doypack machine-the machine for your current and future needs! The functions of the packing system mainly are conveying, weighing, filling and bag sealing. The flexibility of it allows you to customize your machine to meet your individual requirements!

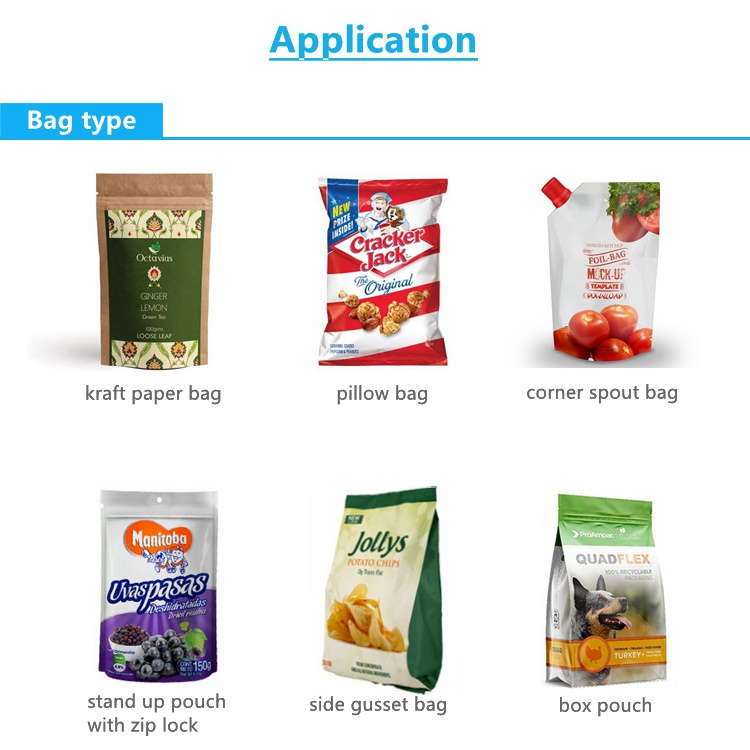

Doypack machine is suitable for all kinds of the premade bags, such as stand up pouch, zipper bag, box pouch, kraft paper bags, corner spout bags and so on

Besides, by connecting with different weighing equipments, the packing system can handle various products, such as powder, snacks, dried vegetable or fruit, puffed food, liquid sauce, beverage, etc

Besides, by connecting with different weighing equipments, the packing system can handle various products, such as powder, snacks, dried vegetable or fruit, puffed food, liquid sauce, beverage, etc

Product Paramenters

Function and characteristics:

1. Easy to operate

2. Automatic checking: no pouch or pouch open error, no fill, no seal, avoid wasting

2. Automatic checking: no pouch or pouch open error, no fill, no seal, avoid wasting

3. Safety device: Machine stop at abnormal air pressure, heater disconnection alarm

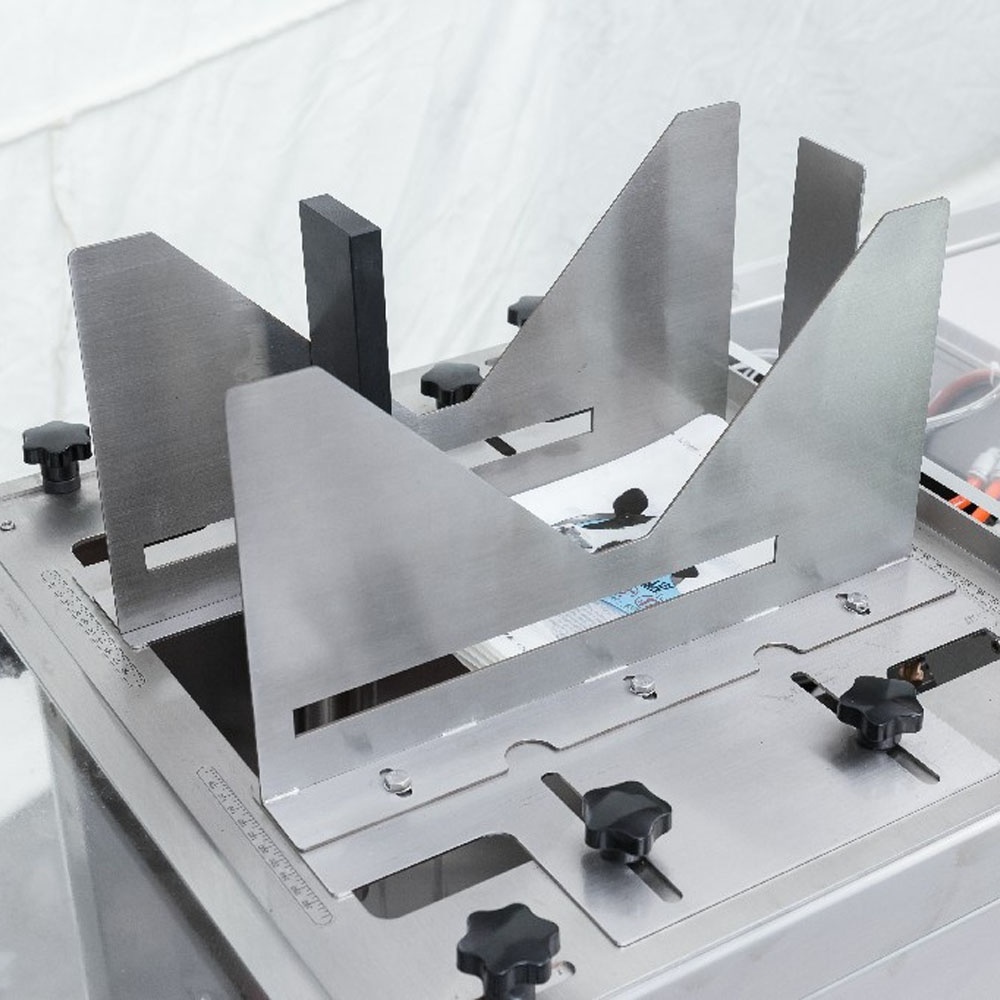

4. Adjustable bag width

5. Glass safety door: It will stop working when you open the door, ensure the safety of operators

6. Low loss of packing materials, high quality of the sealing part, to improved the product specification

7. Different feeding hoppers: for solid, liquid, thick liquid ,powder and so on

8. Bag materials: Suits in extensive range

4. Adjustable bag width

5. Glass safety door: It will stop working when you open the door, ensure the safety of operators

6. Low loss of packing materials, high quality of the sealing part, to improved the product specification

7. Different feeding hoppers: for solid, liquid, thick liquid ,powder and so on

8. Bag materials: Suits in extensive range

|

Specifications

|

|

|

|

|||

|

Model No.

|

TOPY-MDP1

|

TOPY-MDP2

|

TOPY-MDP3

|

|||

|

Bag Width

|

70-280mm

|

70-280mm

|

70-330mm

|

|||

|

Bag Length

|

80-320mm

|

80-440mm

|

80-440mm

|

|||

|

Bag Type

|

Stand-up bag, pillow bag, zipper bag, box pouch

|

|

|

|||

|

Power Supply

|

110V/220V/380V/415V, 50/60HZ

|

|

|

|||

|

Air Consumption

|

7.0 CFM@80 PSI 0.14m3/m3

|

|

|

|||

|

Pneumatic Parts

|

PIAB Vacuum Generator, Pneumatics component Airtac from Taiwan

|

|

|

|||

Packing Solution

The filling system is just for your reference. We will offer you best solution according to your product mobility, viscosity, density, volume, dimensions etc.

A. Powder Packing Solution

A. Powder Packing Solution

Servo Screw Auger Filler is specialized for powder filling such as nutrients powder, seasoning powder,

flour, medicinal powder, etc.

B. Liquid Packing Solution

Piston Pump Filler is specialized for liquid filling such as water, juice, laundry detergent, ketchup etc.

C. Solid Packing Solution

Combination multi-head weigher is specialized for solid filling such as candy, nuts, pasta, dried fruit and vegetable etc.

D. Granule Packing Solution

Linear weigher is specialized for granule filling such as chemical, beans, salt, seasonings etc.

flour, medicinal powder, etc.

B. Liquid Packing Solution

Piston Pump Filler is specialized for liquid filling such as water, juice, laundry detergent, ketchup etc.

C. Solid Packing Solution

Combination multi-head weigher is specialized for solid filling such as candy, nuts, pasta, dried fruit and vegetable etc.

D. Granule Packing Solution

Linear weigher is specialized for granule filling such as chemical, beans, salt, seasonings etc.

Dosing System - A.Auger Filler

Dosing System - B.Liquid Lump

Dosing System - C. Multihead Weigher

Dosing System - D. Linear Weigher

Certifications

Customers & Our Team

Hot Searches