- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

reference the technical parameters

-

Weight:

-

22000 KG

-

Material:

-

steel,Q235, channel steel, cast steel,ZGMn13

-

color:

-

up to you

-

installation:

-

guide by our engineer

-

manufacture stanard:

-

accord with industrial standard

-

spare parts:

-

supply by us

-

quality control:

-

go through five checks

-

after sale service:

-

the whole using life

-

company experience:

-

over 35 years' experience

-

delivery:

-

timely

-

price:

-

reasonable and competitive

Quick Details

-

Capacity(t/h):

-

10-80

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ

-

Dimension(L*W*H):

-

reference the technical parameters

-

Weight:

-

22000 KG

-

Material:

-

steel,Q235, channel steel, cast steel,ZGMn13

-

color:

-

up to you

-

installation:

-

guide by our engineer

-

manufacture stanard:

-

accord with industrial standard

-

spare parts:

-

supply by us

-

quality control:

-

go through five checks

-

after sale service:

-

the whole using life

-

company experience:

-

over 35 years' experience

-

delivery:

-

timely

-

price:

-

reasonable and competitive

Application of ball mill :

Balll mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.ing process.

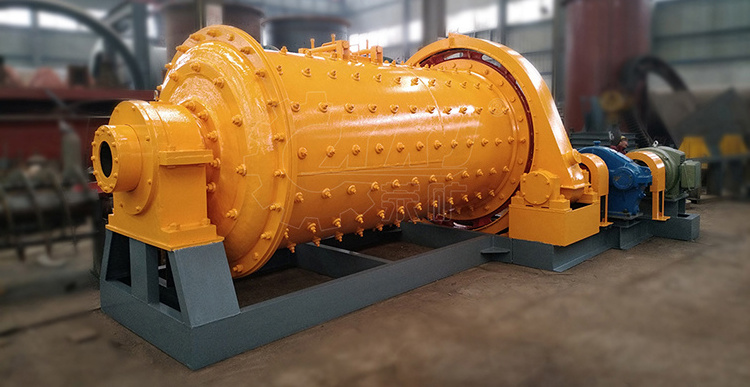

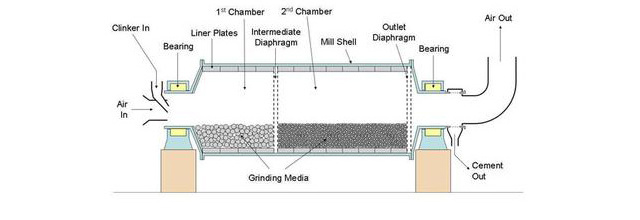

Structure of ball mill :

The machine is composed by feeding part, discharging part, rotation part and driving part (reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The rotation big gearwheel is made by cast hobbling processing and the drum is equipped with wear-resistant liner, which has good wear-resistance. The machine is with stable and reliable working condition. Moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills for choice.

ball mill operating Principle:

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of ceramic ball in the chamber. The centrifugal force caused by rotation of barrel brings the ceramic ball to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

ball mill machine Advantages:

(1)Our

Ball Mill

can be used to dry grinding or wet grinding;

(2) operating conditions are good, grinding machine in a confined within, there is no dust flying;

(3) operation and reliable, grinding cheap, and easy to replace;

(4) can be intermittent operation , but also continuous operation;

(5) crush explosive materials, the mill can be filled into the inert gases instead of air.

Technical Parameters of ball mill:

Ball mill using site:

In order to give you a responsible quotation of Ball Mill, you can inform us the following information

:

1. What's the material you are going to deal with?

2. What's the granularity of the material?

3. What's the granularity of the final products are you going to achieve?

4. What's the producing capacity per hour?

5. Wet or dry type