- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

customized

-

Weight:

-

0.3 KG

-

Application:

-

for gold/tin/tungsten/coltan/chrome ore concentration

-

Keywords:

-

Shaking table

-

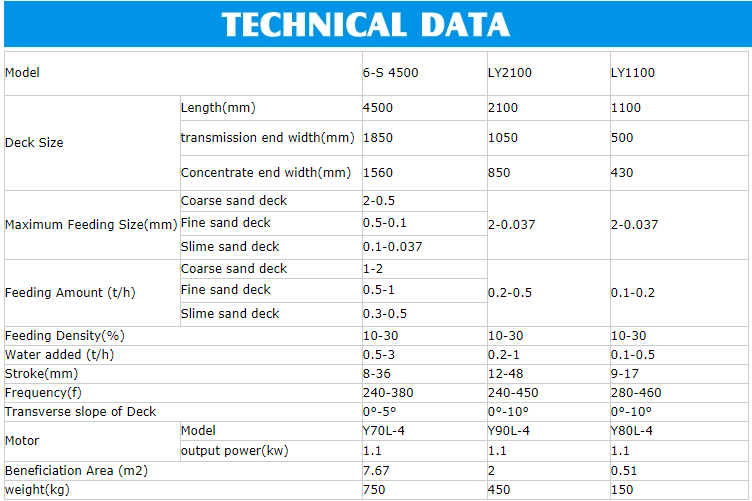

Desk size:

-

4500x1850mm

-

Desk material:

-

glass fiber reinforced plastics with emery

-

feeding density:

-

10%-30%

-

motor:

-

380v/50hz/3phase

-

stroke:

-

8-36mm

Quick Details

-

Production Capacity:

-

10T-60T/D

-

Place of Origin:

-

Jiangxi China

-

Brand Name:

-

JXSC

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

customized

-

Weight:

-

0.3 KG

-

Application:

-

for gold/tin/tungsten/coltan/chrome ore concentration

-

Keywords:

-

Shaking table

-

Desk size:

-

4500x1850mm

-

Desk material:

-

glass fiber reinforced plastics with emery

-

feeding density:

-

10%-30%

-

motor:

-

380v/50hz/3phase

-

stroke:

-

8-36mm

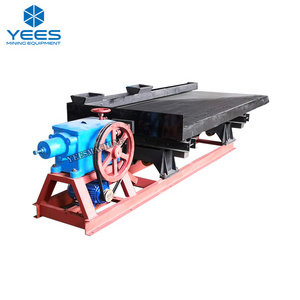

Description of JXSC Shaking Table Separation:

Shaking table is a flagship mining equipment with more than 30 years experiences in JXSC factory.

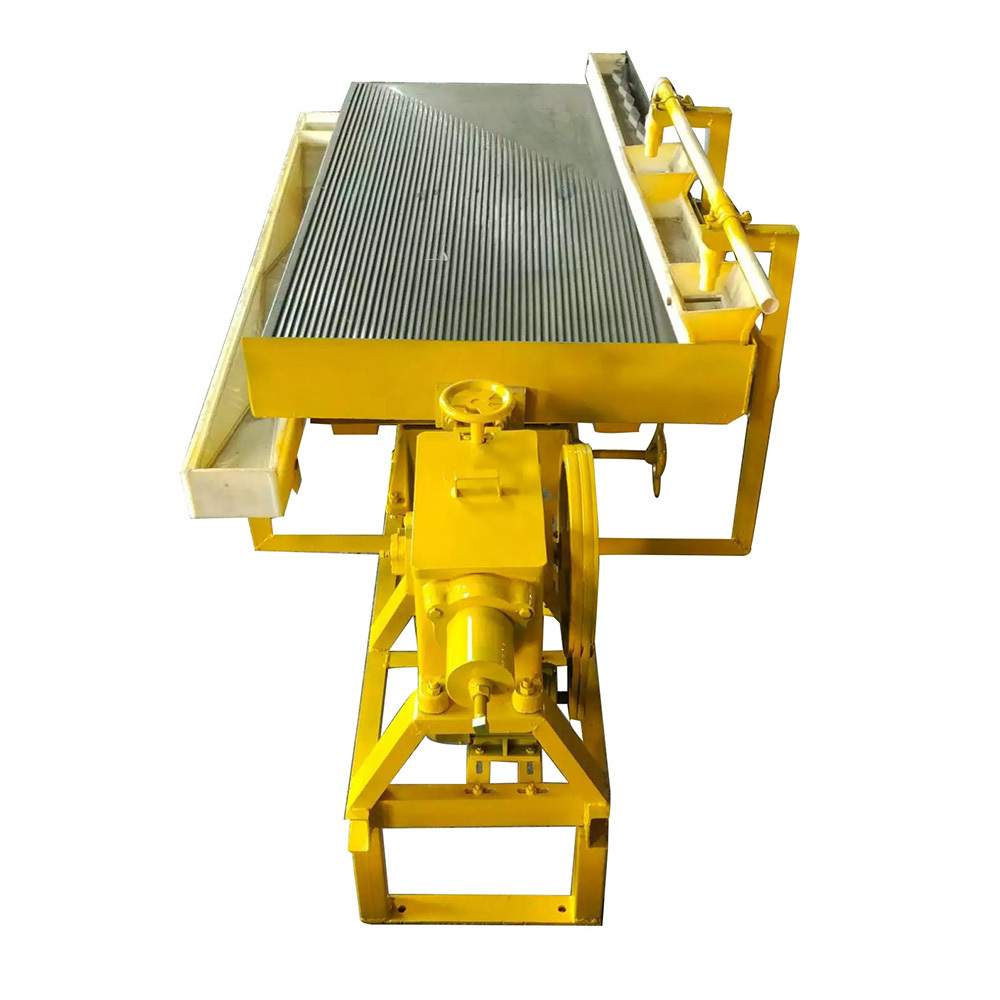

It is a gravity wet process mine machinery, the table deck is made of fiber glass reinforced with wearable corundum surface. Mining shaker table is composed of three parts: head motion of shaking table, table deck of shaking table, as well as bearing and adjusting gradient.

Shaking table widely used to separate gold, tin, tungsten, chromite, silver, diamond, zircon, cobalt, tantalum-niobium, lead, zinc, copper, antimony, other rare metal and noble metal ores.

Working principle of Shaking Table Separation:

The working principle of Cobalt Shaker Table is separate the heavy material from light material by using their different proportion & specific gravity, under the effect of gravity, the minerals will divide into the ore concentrate, the middling and the tailing.

The prominent advantage of ore shaking table is precise separation.

The enrichment ratio of concentrate is very good, up to 95% high recovery ratio for kinds of heavy minerals, when dealing with low grade tungsten ore and tin ore, the enrichment ratio could reach about 300 times.

We can get some final concentrates, final tailings and 1 or 2 kinds of middling products after first separating from the feeding mineral.

Advantages of JXSC Shaking Table Separation

Our new designed mineral shaking table is with better quality than normal 6s shaking table.

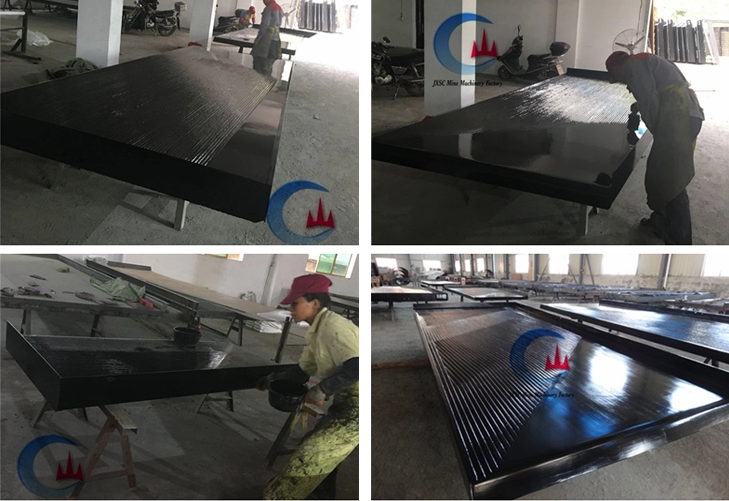

1. Table Desk of Shaking Table Separation :

Made of emery,epoxy resin and fiberglass fabric. first-grade&most wear-resisting Emery can make the table wearproof, long life time. More thicken fiberglass fabric can support the table more stable and stronger.

2. Feeding chute of Shaking Table Separation :

The chute is made of PP material,wearproof.,the old type is wooden which is more easy to be broken.

3. Collection Chute of Shaking Table Separation :

with PP collection chute can collect the concentrate and middling more conveniently, Old type is iron sheet or without this chute.

4. Electric Motor of Shaking Table Separation :

From China famous motor brand,.Also can make SIEMENS brand,customize motor as per request.

5.Channel Frame of shaking table :

#28 big channel frame,50cm more height than normal, so can collect the minerals more conveniently

6. Bearing of shaker table :

from China famous professional bearing manufacturer, Guaranteed quality, long life time.