- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Diffrent Model

-

Weight:

-

4800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

High magnetic field intensity magnetic separator

-

Application:

-

Mining

-

Keywords:

-

Magnet Separator

-

Feeding size:

-

0.074-2mm

-

Material:

-

Stainless Steel

-

Installation:

-

Engineer Guide

-

Capacity:

-

30-200 TPH

-

Rated Background magnetic field:

-

1.4-2.2T

-

magnetizing Current:

-

42-180A

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GUOTE

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Diffrent Model

-

Weight:

-

4800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

High magnetic field intensity magnetic separator

-

Application:

-

Mining

-

Keywords:

-

Magnet Separator

-

Feeding size:

-

0.074-2mm

-

Material:

-

Stainless Steel

-

Installation:

-

Engineer Guide

-

Capacity:

-

30-200 TPH

-

Rated Background magnetic field:

-

1.4-2.2T

-

magnetizing Current:

-

42-180A

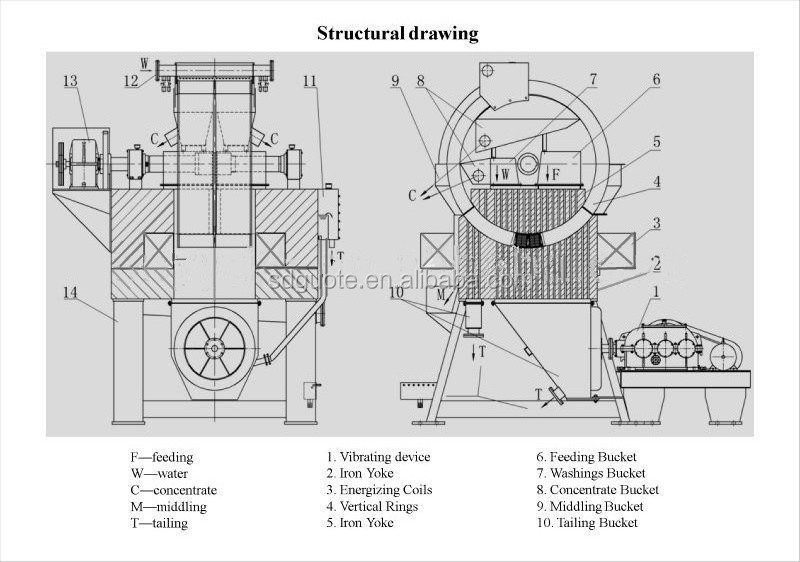

High magnetic field intensity coltan magnetic separator

GTLH Series high gradient magnetic separator is a new product developed independently by GUOTE. It combines the characteristics of international advanced high intensity magnetic separators, which is so far the high intensity magnetic separator of best performance and most advanced technology. This product utilizes vertical ring rotation, pulsating beneficiation and high frequency vibrator, and it has no magnetic medium jam problem in flat ring high intensity magnetic separator and flat ring high gradient magnetic separator.

It has the advantages of large beneficiation ratio, high security and convenient operation etc. This product realizes both high beneficiation ratio and high recycle ratio in separating weak magnetic minerals.

Specifications of cement vibrating feeder

|

Model Part |

GTLH -50 |

GTLH -75 |

GTLH -100 |

GTLH -125 |

GTLH -150 |

GTLH -175 |

GTLH -200 |

GTLH -250 |

|

Ring diameter (mm) |

500 |

750 |

1000 |

1250 |

1500 |

1750 |

2000 |

2500 |

|

Particles size mm (-200 mesh) |

-1.0(30-100) |

-1.0(30-100) |

-1.3(30~100) |

-1.3(30~100) |

-1.3(30~100) |

-1.3(30~100) |

-1.3(30~100) |

-1.3(30~100) |

|

Slurry density (%) |

10~40 |

10~40 |

10~40 |

10~40 |

10~40 |

10~40 |

10~40 |

10~40 |

|

Slurry throughput (m3/h) |

0.5~1.0 |

1.0~2.0 |

12.5~20 |

20~50 |

50~100 |

75~150 |

100~200 |

180~450 |

|

Handling capacity (t/h) |

0.05~0.25 |

0.1~0.5 |

4~7 |

10~18 |

20~30 |

30~50 |

50~80 |

80~150 |

|

Rated back ground Field intensity (T) |

0~1.1 |

0~1.1 |

0~1.1 |

0~1.1 |

0~1.1 |

0~1.1 |

0~1.1 |

0~1.1 |

|

Energizing current (A) |

0~1200 |

0~850 |

0~650 |

0~850 |

0~950 |

0~1200 |

0~1200 |

0~1400 |

|

Energizing voltage (V) |

0~8.3 |

0~13 |

0~26.5 |

0~23 |

0~28 |

0~31 |

0~35 |

0~45 |

|

Energizing power (KW) |

0~10 |

0~11 |

0~17 |

0~19 |

0~27 |

0~37 |

0~43 |

0~63 |

|

Ring motor power (KW) |

0.37 |

0.55 |

1.5 |

2.2 |

4 |

4 |

5.5 |

11 |

|

Vibration motor power (KW) |

0.55 |

0.75 |

2.2 |

2.2 |

4 |

4 |

7.5 |

11 |

|

Water supply pressure (MPa) |

0.1~0.2 |

0.1~0.2 |

0.2~0.4 |

0.15~0.3 |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

|

Water consumption (m3/h) |

0.75~1.5 |

5~8 |

10~20 |

30~45 |

60~90 |

80~120 |

100~150 |

200~300 |

|

Cooling water (m3/h) |

1.5~2 |

1.5~2 |

2~2.5 |

2.5~3 |

3~4 |

4~5 |

5~6 |

6~7 |

|

Main frame weight (t) |

1.5 |

3 |

6 |

14 |

20 |

32 |

48 |

105 |

|

Overall dimension(mm) |

1900*1580 *1320 |

2000*1360 *1680 |

2700*2200 *2560 |

3045*2320 *2640 |

3400*3060 *3150 |

3900*3400 *3800 |

4290*3610 *4320 |

5800*5000 *5400 |

Features

l Application field

1. Updating Ferrous Metals: Martite, Hematite, Siderite, Chromite, Ilmenite, Manganese, Etc.

2. Separating Non-Ferrous Metals: Wolframite and Quartz, Pyrrhotite and Cassiterite, Wolframite and Cassiterite, Limonite Purifying, Scheelite, Wolframite and Garnet, Etc.

3. Recovering Rare Earth: Tantalum and Niobium, Lepidomelane, Monazite, Etc.

4. Brightening Non Metals: Quartz, Feldspar And Kaolin for Ceramics, Sillimanite, Cassiterite, Andalusite, Kyanite for Refractory, and Separating Impurities From Hornblende, Mica, Tourmaline, Garnet, Etc,

l Technical features

1. Vertical Ring Rotation & Pulsating Beneficiation

2. High Frequency Vibration Mechanism

3. Wide Range of Feed Particle Size

4. Multi-Gradient Matrixes & Liquid Level Control System.

These technologies improve the grade of magnetic concentrate and recovery.

5. Frequency Conversion Step-less Adjustment for Rotary Speed & Vibrating Frequency.

6. No Stepper Phenomenon of Rotary Rings

1. Packaging: Specially made wooden boxes and containers.Equipment painting completed before shipment, With Stretch film to avoid rub off the surface paint, It can used wooden cases packaging according to users requirements.(Key parts such as electric cabinet with shockproof packaging material and then packed in wooden cases. )

2 Shipping: 5-45 days after receiving initial payment .Meanwhile our company has a long-term cooperation with ACL, CSCL, CCNI,CNC, COSCO etc insure the goods to the port on time.

3. We have 15 experienced engineers, With 108 skilled workers insure good quality of our machines and prompt delivery.

Pre-sales Service:

The wide product range enables us to provide our customers with individual machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions, and we produce strictly follow customers’ order. What’s more, every customer has the chance to visit the working machine in the site before placing the order.

Most of the visiting foreign customers feel inconvenient for the first time. Due to this condition, we help to arrange cars, hotels, and translators for every visiting customer.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees, and installation engineers. The installation technicians are special and professional team of SBM; they are now strategically located home and abroad, working for our customers

Contact Information-

Annie Chang

Mob: +8618678029069(WhatsApp/wechat)

Skype:anna1983cyj ,QQ:896247401

Email:annieflower.chang at sdguote.com

website: https://sdguote.cnen.alibaba.com/

If you have any questions, pls don't hesitated to contacting me anytime.