- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

30

-

Range of Spindle Speed(r.p.m):

-

0 - 1450 r.p.m

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FARFLY

-

Voltage:

-

220V/380V

-

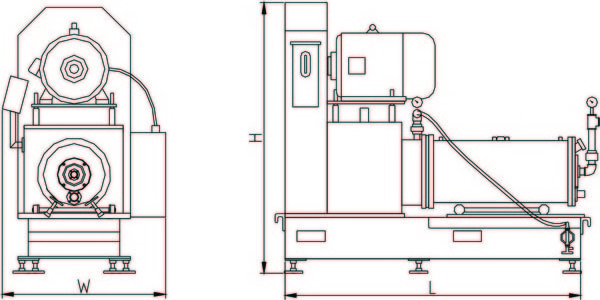

Dimension(L*W*H):

-

2850*2380*1400mm

-

Weight (KG):

-

1200 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

bead mill

-

Substrate:

-

oil /water based

-

Weight:

-

1200KG

-

Capacity:

-

100-800kg/h

-

Function:

-

Grinder Flour Powder Machine

-

Grinding media:

-

95% Zirconia Beads

-

Color:

-

Clients' Requirement

Quick Details

-

Output (kg/h):

-

500 - 2500 kg/h

-

Feeding Size (mm):

-

350 - 400 mm

-

Output Size (mesh):

-

35 - 40 mesh

-

Power (kW):

-

30

-

Range of Spindle Speed(r.p.m):

-

0 - 1450 r.p.m

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FARFLY

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

2850*2380*1400mm

-

Weight (KG):

-

1200 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

bead mill

-

Substrate:

-

oil /water based

-

Weight:

-

1200KG

-

Capacity:

-

100-800kg/h

-

Function:

-

Grinder Flour Powder Machine

-

Grinding media:

-

95% Zirconia Beads

-

Color:

-

Clients' Requirement

- High flux--technology imported from Germany: static centrifugal discharging devices, large discharge area with high

output

- Double mechanical seal, lubricationg liquid dissolves with material, safe and reliable.

- Grinding area is made of specila anti-wearing alloy ensuring long sevice life.

- Cooling efficiency: segmented double helix water way which is more advantageous to the energy exchange. Cooling

efficiency is 2 times better than ordinary types.

- Intelligent double mechanical seals: German mechanical seal technology, imported-fluorine sealing rings can resist

different solvents

- Grinding efficiency: increased to more than 30% compared with regular models, the combination of the disper can rapidly

improve dispersion efficiency. The grinding medium can be superfine size to be more efficient.

|

type/parameter

|

power Kw

|

barrel capacity L

|

pump flux L/min

|

cooling water m3/h

|

production capacity kg/h

|

milling medium mm

|

size L*W*H mm

|

|

FSP-30

|

22

|

30

|

2-17

|

1.5-2

|

80-600

|

0.4-2.0

|

1620*930*1610

|

|

FSP-50

|

30

|

50

|

3-22

|

2-2.5

|

100-800

|

0.4-2.0

|

1780*930*1780

|

|

FSP-60

|

37

|

60

|

3-22

|

2-2.5

|

100-1000

|

0.4-2.0

|

2000*1900*1000

|

|

FSP-100

|

55

|

100

|

5-40

|

2.5-3

|

200-1500

|

0.4-2.0

|

2100*1170*1930

|

|

FSP-200

|

110

|

200

|

8-60

|

4-5.5

|

500-2500

|

0.4-2.0

|

2850*2380*1400

|

Hot Searches