- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Garlic Peeler Line Nigeria Fresh Garlic Processing Machine

-

Material:

-

SUS304

-

Function:

-

Multifunctional

-

Feature:

-

Automatic

-

Applicable Industries:

-

Food & Beverage Factory, Farms, Restaurant, Food Shop, Food & Beverage Shops

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

Viet Nam

-

Showroom Location:

-

None

-

Video outgoing-inspection:

-

Provided

-

Machinery Test Report:

-

Provided

-

Marketing Type:

-

New Product 2021

-

Warranty of core components:

-

1 Year

-

Core Components:

-

PLC, Engine, Motor

-

Condition:

-

New

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

CE ISO

-

Type:

-

GARLIC PEELING MACHINE

Quick Details

-

Brand Name:

-

GELGOOG

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380V

-

Product name:

-

Garlic Peeler Line Nigeria Fresh Garlic Processing Machine

-

Material:

-

SUS304

-

Function:

-

Multifunctional

-

Feature:

-

Automatic

-

Applicable Industries:

-

Food & Beverage Factory, Farms, Restaurant, Food Shop, Food & Beverage Shops

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

Viet Nam

-

Showroom Location:

-

None

-

Video outgoing-inspection:

-

Provided

-

Machinery Test Report:

-

Provided

-

Marketing Type:

-

New Product 2021

-

Warranty of core components:

-

1 Year

-

Core Components:

-

PLC, Engine, Motor

-

Condition:

-

New

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

CE ISO

-

Type:

-

GARLIC PEELING MACHINE

Products Description

Automatic Garlic Powder Production Line Introduction:

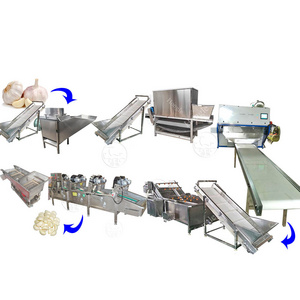

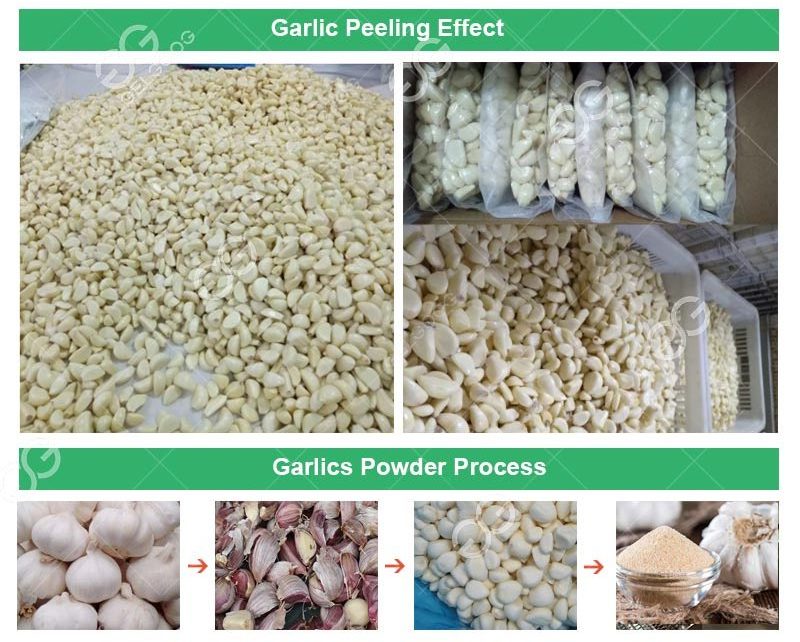

This garlic powder production line is mainly used for garlic separating and peeling in large quantity, it includes elevator, garlic bulbs separating machine, picking line, garlic peeling machine and finished product picking line. Equipped with slicing machine, dicing machine, bubble cleaning machine, air dryer, drying machine, and other equipment, the garlic separating and peeling production line can be used to do garlic deep processing like dehydrated garlic slices, garlic powder, mashed garlic, onion and other products. Adopting advanced technology and high garlic yield, it is currently the most ideal equipment for garlic processing.

Manufacturing Technique

The flowchart of garlic separating and peeling production includes the following steps:

Garlic--Root Cutting--Grading--elevating--garlic bulb separating--picking--elevating--garlic peeling--Washing--Cooling--Slicing--Dehydrating--Grinding--final product picking--packing

1. Elevator: the elevator is used to send the garlic into the separating machine and peeling machine evenly.

2. Garlic bulbs separating machine: separating the garlic bulbs into garlic cloves which can be used to peel. Stripping rate can reach 98%.

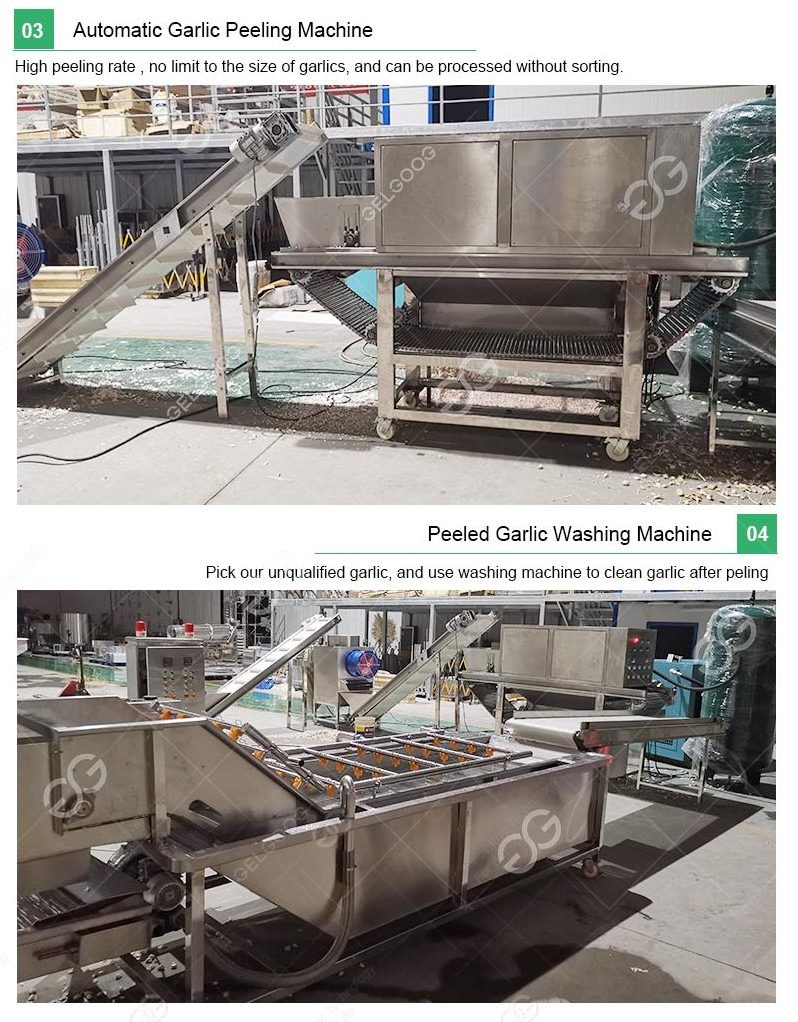

3. Garlic peeling machine: using air automatic peeling, automatic separation of skin and garlic cloves, peeling clean and

damage-free.

4. Picking line: pick the unqualified garlic by manual picking to improve the garlic quality.

2. Garlic bulbs separating machine: separating the garlic bulbs into garlic cloves which can be used to peel. Stripping rate can reach 98%.

3. Garlic peeling machine: using air automatic peeling, automatic separation of skin and garlic cloves, peeling clean and

damage-free.

4. Picking line: pick the unqualified garlic by manual picking to improve the garlic quality.

|

Machine Mane

|

Power

|

Voltage

|

Dimension

|

|

Garlic Peeling Machine

|

2.2 kw

|

380V50Hz3PH

|

1800*850*800mm

|

|

Garlic Picking Belt

|

0.75kw

|

380V50Hz3PH

|

3000*800*900mm

|

|

Garlic Slicing Machine

|

1.1kw

|

220V50Hz1PH

|

690*560*880mm

|

|

Elevator

|

0.75kw

|

380V50Hz3PH

|

1800*800*1600mm

|

|

Garlic Blenching Machine

|

60 kw

|

380V50Hz3PH

|

4000*1100*1400 mm

|

|

Garlic Drying Machine

|

300kw

|

380V50Hz3PH

|

10000*2200*2000mm

|

|

Elevator

|

0.75kw

|

380V50Hz3PH

|

2000*1200*1400mm

|

|

Garlic Powder Grinding Machine

|

11kw

|

380V50Hz3PH

|

7000*1000*2400mm

|

|

Garlic Power Packing Machine

|

4kw

|

380V50Hz3PH

|

700*900*2100mm

|

Product Paramenters

Recommend Products

FAQ

Q. What are the processing steps of the ginger powder processing line?

A. Ginger washing and peeling machine - Ginger blanching machine - Ginger Slicing Machine - Ginger drying machine - Ginger powder grinding machine.

Q. How about the finished product fineness?

A. General materials 20-120 mesh,

100 mesh is the best in actual use.

Q. How to adjust the fineness of the ginger powder grinding machine?

A. Adjust the turmetic grinder machine fineness by changing the size of the screen. The size of the screen is 85*910mm.

Q. What is the material of the turmetic powder making machines?

A. The main turmetic powder grinding machine is made of carbon steel, and the material is in contact with the outer material of 304 stainless steel.

Q. What are the requirements for material processing?

A. The moisture content of the material is less than 5%, and the oil content is less than 20%.

Q. How to clean up the turmetic ginger powder grinder machine?

A. You can wipe the dry turmetic ginger powder grinding machine with a high degree of alcohol.

Customer Photos

Our Factory

Tina Name Card

Hot Searches