The grille is located above the feed hopper. It

is made of round steel with a diameter of 20mm and an interval of 50mm. The grille blocks larger diameter materials from the

hopper and prevents larger materials from entering the hopper from clogging and damaging the screen cylinder.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3000x800x1640

-

Weight:

-

600 KG

-

Customizable:

-

logo / packing / graphic

-

Installation:

-

supply manual to guide user

-

Feeding size:

-

less than 300mm

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sinolion

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3000x800x1640

-

Weight:

-

600 KG

-

Customizable:

-

logo / packing / graphic

-

Installation:

-

supply manual to guide user

-

Feeding size:

-

less than 300mm

Product Description

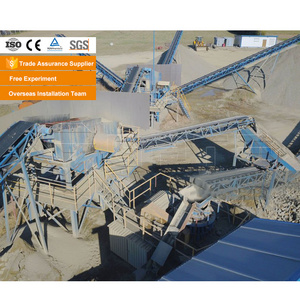

This 10 tons per hour capacity gold washing plant equipped with a reversible wet material hopper and screen. This machine is perfect for small scale miners or as a testing plant.Little water consumption but high efficient enrichment capability, equipped with a wide sluice box which need clean up just when batch test or after one day work. At the same time can provide you around 98% recovery rate. Recovery fineness can reach 300 mesh. With continuous processing, advanced reverse helix system, help you increase the gold recovery rate, lower ability to the operation of the operator.

Working Principle

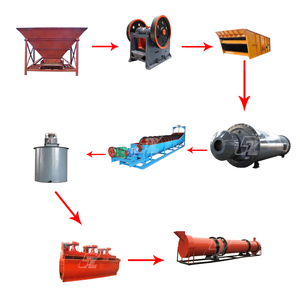

1

>

Raw material feeding

The raw material input through the hopper inlet is pushed into the screen drum by the powerful water pressure of the nozzle loaded in the hopper.

2> Washing

The screen barrel has a built-in galvanized seamless water spray pipe (diameter 42mm), and the raw materials are washed by water and selected through the gold panning tank through the rotation of the trommel screen.

3> Fine gold collection

Light dirt and sand are washed away by the water, and heavier gold will gather in the gold blanket.

Grille

Screen drum

The drum part is woven of manganese wire,the aperture of manganese wire screen is usually 5mm, and the range of customization is 2mm-80mm, which can be made according to customer requirements. And the manganese wire material is durable, not easy to corrode and block, and can be replaced.

Technical Parameters

|

Model

|

Capacity (t/h)

|

Power (kw)

|

Diameter (mm)

|

Length(mm)

|

Discharge(mm)

|

Input(mm)

|

Dimension (mm)

|

|

GMTS0519

|

5—10

|

1.5

|

500

|

1910

|

≤300

|

0—100

|

3000*1000*1800

|

|

GMTS1020

|

10—30

|

4

|

1000

|

2000

|

≤300

|

0—100

|

3200*1400*1900

|

|

GMTS1225

|

30—50

|

5.5

|

1200

|

2500

|

≤300

|

0—100

|

4300*1650*2220

|

|

GMTS1548

|

80—150

|

11

|

1500

|

4800

|

≤300

|

0—100

|

8000*2200*3600

|

|

GMTS1848

|

100—200

|

15

|

1800

|

4800

|

≤300

|

0—100

|

8000*2200*4000

|

More models

Case

Packing & Delivery

Ways Of Packing

1.Small parts packed in the wooden cases

2.Big parts or the whole big machine is loaded in the container by the Ocean Shipping or others.

Hot Searches