- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depends on the capacity of boiler

-

Weight:

-

Depends on the capacity of size

-

Product name:

-

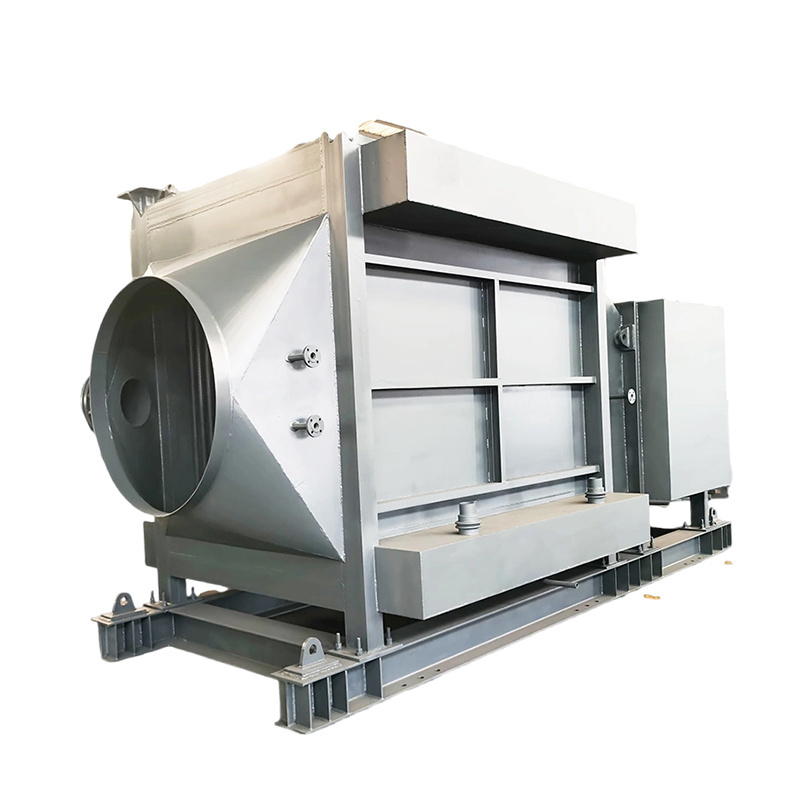

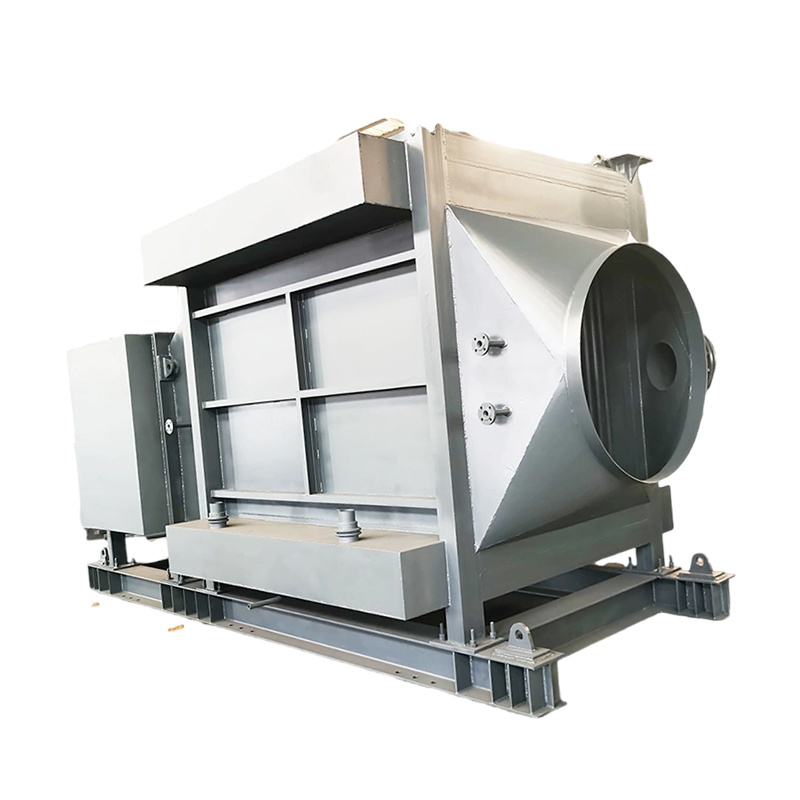

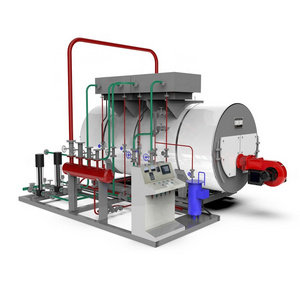

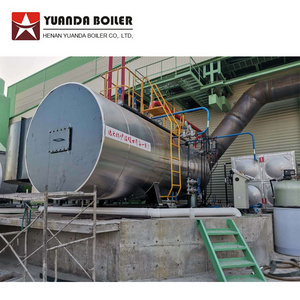

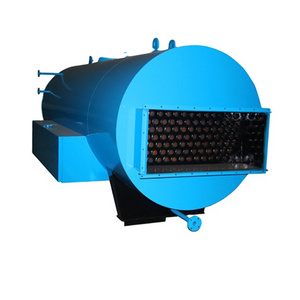

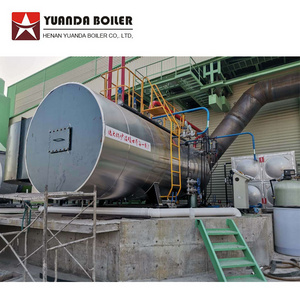

waste heat exhaust gas boiler

-

Installation method:

-

Assembling boiler

-

Outlet pressure:

-

low pressure

-

Boiler Usage:

-

industrial boiler

-

boiler type:

-

Hot water boiler

-

Water level volume:

-

≥30L

-

Rated thermal power:

-

<0.1MW

-

Rated steam pressure:

-

<0.1Mpa

-

Outlet water pressure:

-

≥0.1MPa

-

Working water pressure:

-

>0.3MPa

Quick Details

-

Core Components:

-

Boiler main body

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Anxin

-

Dimension(L*W*H):

-

Depends on the capacity of boiler

-

Weight:

-

Depends on the capacity of size

-

Product name:

-

waste heat exhaust gas boiler

-

Installation method:

-

Assembling boiler

-

Outlet pressure:

-

low pressure

-

Boiler Usage:

-

industrial boiler

-

boiler type:

-

Hot water boiler

-

Water level volume:

-

≥30L

-

Rated thermal power:

-

<0.1MW

-

Rated steam pressure:

-

<0.1Mpa

-

Outlet water pressure:

-

≥0.1MPa

-

Working water pressure:

-

>0.3MPa

Product Description

Specification

|

Product Features

|

|

|

|

|

||||

|

The high-temperature flue gas released from coal combustion is transported through the flue to the inlet of the waste heat boiler,then flows through the heat exchanger, evaporator, and economizer, and finally discharged into the atmosphere through the chimney.The exhaust temperature is generally 150-180 ℃, and the heat released by the flue gas temperature dropping from high temperature to exhaust temperature is used to convert water into steam. The boiler feedwater first enters the economizer, where the water absorbs heat and heats up to a saturation temperature slightly lower than the drum pressure before entering the drum. After the water entering the drum is mixed with the saturated water inside the drum, it enters the evaporator along the downcomer below the drum to absorb heat and start producing steam. Usually, only a portion of the water becomes steam, so the mixture of steam and water flows inside the evaporator. The steam water mixture leaves the evaporator and enters the upper drum for separation through

steam water separation equipment. Water falls into the water space inside the drum and enters the downcomer to continue absorbing heat and producing steam. Steam enters the superheater from the upper part of the drum, absorbing heat and turning saturated steam into superheated steam. According to the three stages of the steam production process corresponding to the three heating surfaces,namely the economizer, evaporator, and superheater, if no superheated steam is needed, only saturated steam is needed, and a superheater may not be installed. When there is reheated steam, a reheater can be added. |

|

|

|

|

||||

Hot Searches