- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product

-

Warranty of core components:

-

1 years

-

Brand Name:

-

Leguang

-

Voltage:

-

380

-

Power:

-

3kw

-

Dimension(L*W*H):

-

1200*1100*1050mm

-

Weight:

-

600

-

Product name:

-

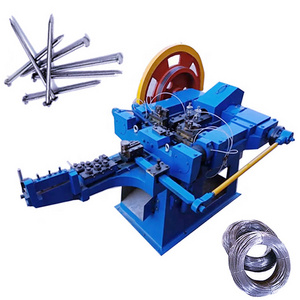

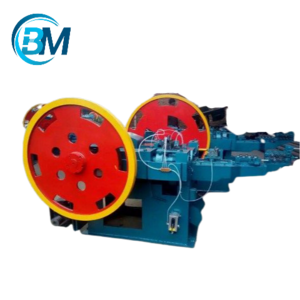

screw making machine

-

Max Diameter:

-

M6

-

Max Length:

-

65mm

-

Tagging specifications:

-

M6*65mm

-

Type:

-

Full Automatic

-

Motor Power:

-

3KW

-

Model:

-

DH-15

-

Color:

-

Blue and Green

-

Machine Type:

-

colHeading machine

-

Usage:

-

make screws,rivets,bolts

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Application:

-

thread rolling

-

Production Capacity:

-

200-250pcs/Min

-

Marketing Type:

-

New Product

-

Warranty of core components:

-

1 years

-

Brand Name:

-

Leguang

-

Voltage:

-

380

-

Power:

-

3kw

-

Dimension(L*W*H):

-

1200*1100*1050mm

-

Weight:

-

600

-

Product name:

-

screw making machine

-

Max Diameter:

-

M6

-

Max Length:

-

65mm

-

Tagging specifications:

-

M6*65mm

-

Type:

-

Full Automatic

-

Motor Power:

-

3KW

-

Model:

-

DH-15

-

Color:

-

Blue and Green

-

Machine Type:

-

colHeading machine

-

Usage:

-

make screws,rivets,bolts

Product Description

|

marking screw size

|

M6*65mm

|

|

Max Diameter

|

6mm

|

|

Main die size

|

34.5*80mm

|

|

Host travel

|

92mm

|

|

Dimensions of one or two stamping dies

|

31*65mm

|

|

Shear die size

|

19*35mm

|

|

Scissor size

|

H9*32*65mm(aperture M10*17)

|

|

Production per minute

|

120-170pcs

|

|

Main motor

|

3kw

|

|

Net Machine Weight

|

1250KG

|

|

Machine Size (MM)

|

2000*1100*1200mm

|

|

Color type

|

blue and green

|

|

Provide after-sales service

|

YES

|

|

Warranty period

|

2 years

|

1.Cold Heading Machine

This equipment adopts cold heading way to make the wire rod upsetting by double-click the whole mould form. Finished Feeding,straightening, cutting material, forming, discharging by one machine.

This equipment adopts cold heading way to make the wire rod upsetting by double-click the whole mould form. Finished Feeding,straightening, cutting material, forming, discharging by one machine.

Purpose: Manufacture screw head type and cutting wire set screw length

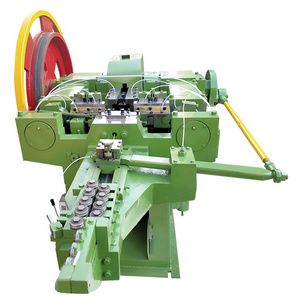

2.Thread Rolling Machine

This equipment adopts two thread profile thread rolling plate staggered 1/2 screw distance design, dead plate is fixed, movable

plate equal to dead plate do straight line motion back and forth, when the work piece feed between two plates, movable plate move

forward twist work piece, make its surface plastic deformation into thread. .

This equipment adopts two thread profile thread rolling plate staggered 1/2 screw distance design, dead plate is fixed, movable

plate equal to dead plate do straight line motion back and forth, when the work piece feed between two plates, movable plate move

forward twist work piece, make its surface plastic deformation into thread. .

Specification

Movement to show

Screw head machine is suitable for all kinds of wire and can manufacture screws of various shapes

Easy to change the mold, production of different sizes of screws, easy to operate

Mold supporting service

We have supporting mold, each machine has produced a sample for customer testing.

Customized production according to customer demand, the production cycle is generally 20 days

Various screw types can manufactured

Our advantages .

1. Focus on screw heading machine and thread rolling machine, with unique technology and experience;

2. Source manufacturer, complete the whole process of product development, design, production and customization independently;

3. Experienced technical team can provide customized services according to customer needs;

Brief introduction of processes and machines needed :

(1). Pull the coarse line to the line patch needed. (Wire drawing machine)

(2). Adjust, produce, and form the head of screw on the heading machine. (Screw heading machine)

(3).Grind tooth on the coil thread rolling machine, and form the screw completely (Thread rolling machine)

(4). Treat the semi-finished screw in the heat treatment according to the standard (Heat treatment furnace)

(5). According to the requirements, process plating etc. (Zinc plating machine)

(6). Packing and out of factory

2. Source manufacturer, complete the whole process of product development, design, production and customization independently;

3. Experienced technical team can provide customized services according to customer needs;

Brief introduction of processes and machines needed :

(1). Pull the coarse line to the line patch needed. (Wire drawing machine)

(2). Adjust, produce, and form the head of screw on the heading machine. (Screw heading machine)

(3).Grind tooth on the coil thread rolling machine, and form the screw completely (Thread rolling machine)

(4). Treat the semi-finished screw in the heat treatment according to the standard (Heat treatment furnace)

(5). According to the requirements, process plating etc. (Zinc plating machine)

(6). Packing and out of factory

Screw making process

FAQ

1. who are we?

We are based in Guangdong, China, start from 1998,sell to South Asia(35.00%),North America(25.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Screw Cold Head Die,Screw,Screw Carbid Die,Heading machine/Thread rolling machine,Screw wire rod

4. why should you buy from us not from other suppliers?

We focus on the production of wall plate nails, drill tail screw, cold heading machine and cold heading die. Our company chooses imported materials, screw moulds are well-known, and exported to Europe, Asia and other countries.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,FAS,DDP,DDU;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,D/P D/A,MoneyGram,Credit Card,Cash,Escrow;

Language Spoken:English,Chinese,Russian

We are based in Guangdong, China, start from 1998,sell to South Asia(35.00%),North America(25.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Screw Cold Head Die,Screw,Screw Carbid Die,Heading machine/Thread rolling machine,Screw wire rod

4. why should you buy from us not from other suppliers?

We focus on the production of wall plate nails, drill tail screw, cold heading machine and cold heading die. Our company chooses imported materials, screw moulds are well-known, and exported to Europe, Asia and other countries.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,FAS,DDP,DDU;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,D/P D/A,MoneyGram,Credit Card,Cash,Escrow;

Language Spoken:English,Chinese,Russian

Hot Searches