SKYWALKERs looking forward to have you comments and consideration. Cannot wat a second to start the business with your esteemed companies.

- Product Details

- {{item.text}}

Quick Details

-

Certification:

-

HALAL, ISO, KOSHER

-

Particle Size:

-

200 mesh

-

Application:

-

Oil Refining

-

Appearance:

-

Grey-white fine powder

-

CAS No:

-

70131-50-9

-

Montmorillonite:

-

Min 90%

-

Bulk Density:

-

0.6-1.1 G/ml

-

Packing:

-

25kg pp/paper bags or jumbo bags

Quick Details

-

Place of Origin:

-

Shandong, China

-

Decoloring Ability:

-

Min95%

-

SiO2:

-

68.5%-73.6%

-

Certification:

-

HALAL, ISO, KOSHER

-

Particle Size:

-

200 mesh

-

Application:

-

Oil Refining

-

Appearance:

-

Grey-white fine powder

-

CAS No:

-

70131-50-9

-

Montmorillonite:

-

Min 90%

-

Bulk Density:

-

0.6-1.1 G/ml

-

Packing:

-

25kg pp/paper bags or jumbo bags

Product Description

|

Brand Name

|

SYKOL

|

|

Decolorizing Ability

|

Min. 96.8%

|

|

Particle Size

|

200 mesh

|

|

pH

|

2.6-3.5

|

|

Moisture

|

Max. 8.0%

|

|

Oil Retention

|

Max. 3.81%

|

|

Free Acid

|

Max. 0.18%

|

|

Bulk Density

|

0.65-0.85 g/mL

|

|

Dosage

|

1-3.0%

|

SYKOL Bleaching clay for Cooking oil Refinery

1). SYKOL could absorb the pigments and impurities out of the crude oil.

2).With the low acidity, SYKOL could protect the oxidant stability of the refined oil and extend its working period.

3).Besides, SYKOL could be helpful to reduce Free Fat Acid, Phosphatides, trace of Heavy Metal and gums from the seeds' surface etc.

SYKOL Bleaching Clay working in diesel regeneration

1). SYKOL clay

has the capability to expend the working life of industrial oils.

2).

SYKOL bleaching earth is regarded as the cracking catalysts and absorption media here.

3).

Long chained polymer and oxidized components were cracked by SYKOL and then removed by distillation

All above reaction would be finished in suspension.

Raw Bentonite mines

SKYWALKER owns the exclusive mining license of local bentonite, with montmorillonite content more than 95% in raw, and SiO2 content no less than 68%, which offers the basic for the high porous structure after activation.

Raw Clay Analysis

Right after explored the bentonite and before production, the clay need to be well treated and tested, only if the SiO2 above standard level, the clay can be activated into the bleaching clay with high bleaching ability.

Charging System

From raw bentonite stockage uploaded to the activation tank, this process was all controlled by digits, so that the charged raw clay volume will be constant, and making sure all the clay can be well activated.

Reaction Tank

Unlike the previous tank, SKYWALKER used the most advanced activation method, to finish the activation process by steps, So that each bentonite granules can be treated by sulphuric acid, and enlarge the surface area.

Package

After the complicated activation process, SYKOL bleaching earth needs a deep washing to remove the extra acidity, This could well protect the clay won't effect the pH condition in refined oil, and extend it's expire time, without any color returning.

Deliver

After quality approved, SYKOL clay can be allowed to sell to the clients. Besides making sure the quality, SKYWALKER also trying the best to make better surface of the SYKOL clay, whatever package you need, we can make it really.

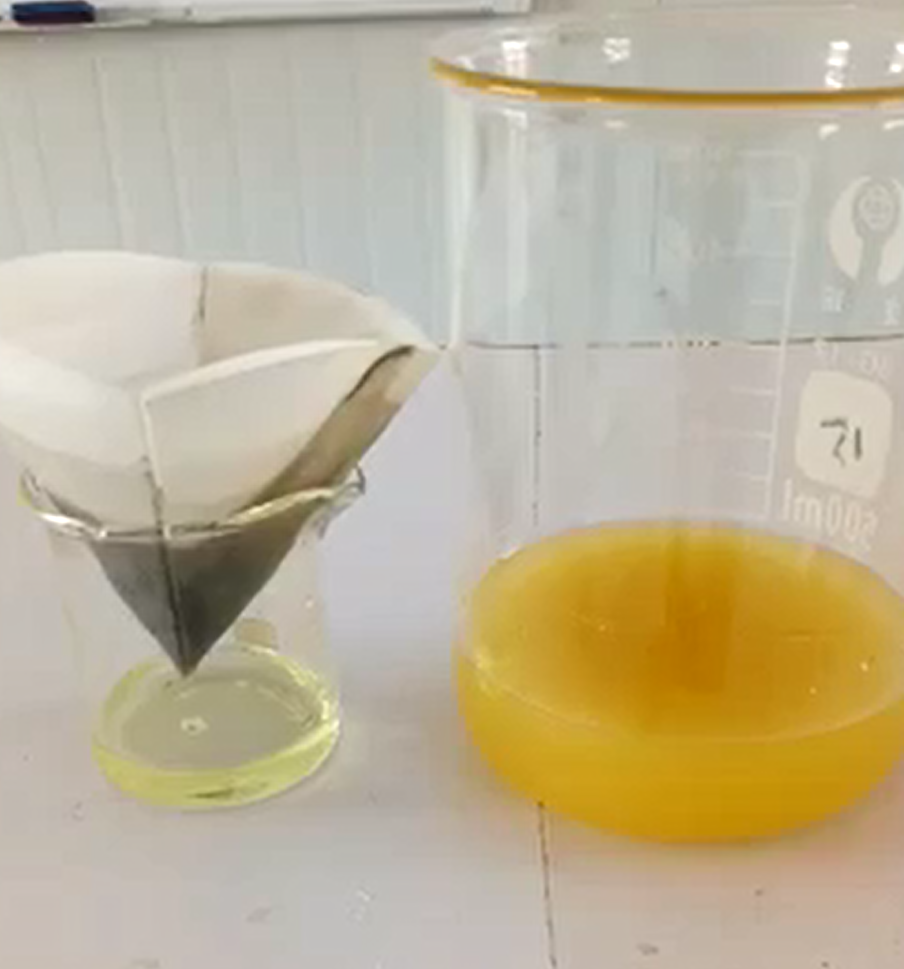

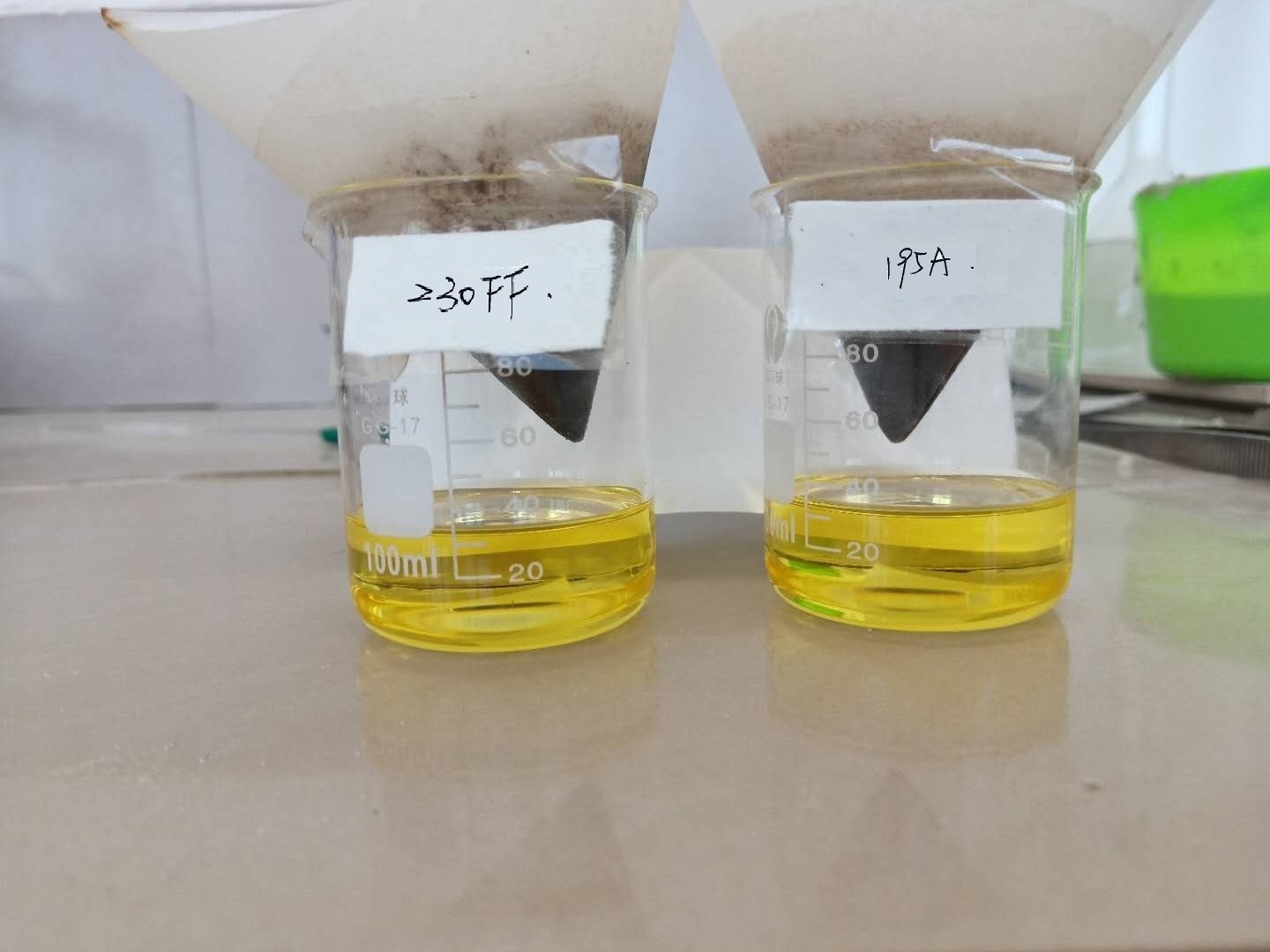

Methylene Blue Absorption ability test

Bleaching Ability Analysis

Refined Cotton Seed oil by dosage 1.5%

HOW SYKOL Bleaching Clay from?

SYKOL Bleaching earth is made from 100% natural Bentonite Clay,

Our factory located in Inner Mongolia, where deposit the most volume and best quality bentonite mines, which consists of more than 90% Montmorillonite clay.

1).Thanks for the layer structure and

octahedral of each montmorillonite particle, the raw material was awarded with more porous surface and layers after treated by H2SO4,

2). After more than 7 times washing of treated bentonite, extra acid components were replaced by H+ and O+.

3).BET Surface area much increased after the ion exchanging, and the absorption ability arisen.

4).After dried by the oven, extra moisture decreased and further arise the absorption ability.

5).Particle Distribution is one of the most important feature to adjust not only absorption ability, but filtration rate also. With more than thousands analysis and collected feedback from the users, 200 mesh particle >95% should be the best situation of this parameter.

HALAL for Ingredients

Health Certificate

HALAL

Whatever requirements you need, believe we have the ability to provide the most suitable and professional service for your demanding.

Hot Searches