Polyurethane edge sealing rock wool board is currently internationally recognized as the best building envelope fire insulation board, with low thermal conductivity, good load resistance, high bending strength, no water absorption, no decay, good flame retardancy, and a large temperature resistance range. By utilizing the physical properties and unique formula of polyurethane (PU/PIR), the polyurethane foaming agent is uniformly sprayed on the color coated steel plate, forming a three-layer disposable polyurethane color steel composite sandwich panel by foaming the foaming agent between the color coated steel plates. The perfect combination of this new lightweight building material and polyurethane is the development direction of lightweight building materials.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

Customized according to customer requirements

-

Product name:

-

PU Sandwich Panel

-

Core material:

-

Rock Wool Board

-

Effective width:

-

400-1120mm

Quick Details

-

Project Solution Capability:

-

graphic design, total solution for projects

-

Application:

-

Leisure Facilities

-

Design Style:

-

Mid-Century Modern

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

Customized according to customer requirements

-

Product name:

-

PU Sandwich Panel

-

Core material:

-

Rock Wool Board

-

Effective width:

-

400-1120mm

You may also like

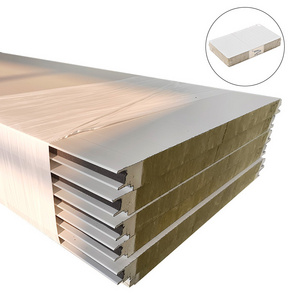

New type of composite sandwich panel

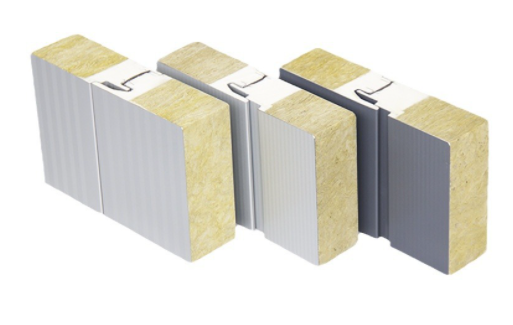

Node diagram:

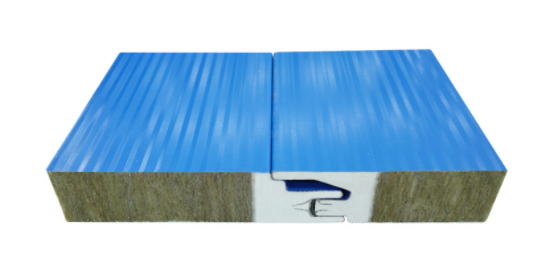

Schematic diagram of hidden PU edge sealing rock wool overlap:

1. Advantages: The use of polyurethane side sealing technology improves the airtightness and water tightness of the overlap, effectively preventing the occurrence of cold bridging phenomenon. At the same time, it overcomes the occurrence of peeling between the steel plate and the core material at the overlapping point during the transportation and installation process of the board.

2. Effective width: 400mm-1150mm

3. Production thickness: 50mm, 75mm, 80mm, 100mm, 120mm, 150mm, 200mm

4. Decorative seam effect: 0mm-20mm

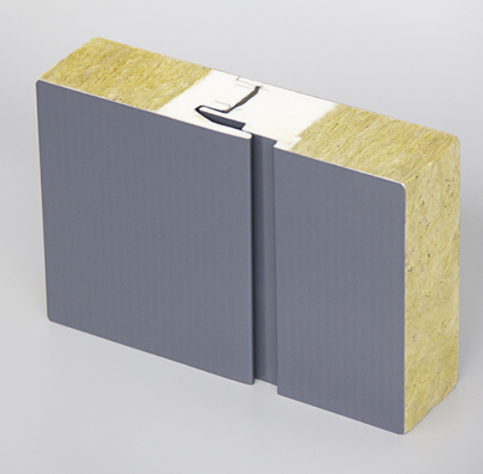

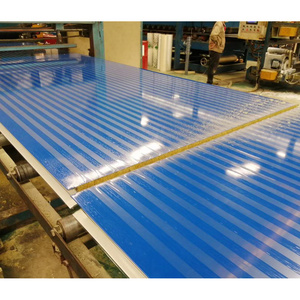

Schematic diagram of concealed PU edge sealing glass fiber cotton overlap:

1. Advantages: The use of polyurethane side sealing technology improves the airtightness and water tightness of the overlap, effectively preventing the occurrence of cold bridging phenomenon. At the same time, it overcomes the occurrence of peeling between the steel plate and the core material at the overlapping point during the transportation and installation process of the board.

2. Effective width: 400mm-1150mm

3. Production thickness: 50mm, 75mm, 80mm, 100mm, 120mm, 150mm, 200mm

4. Decorative seam effect: 0mm-20mm

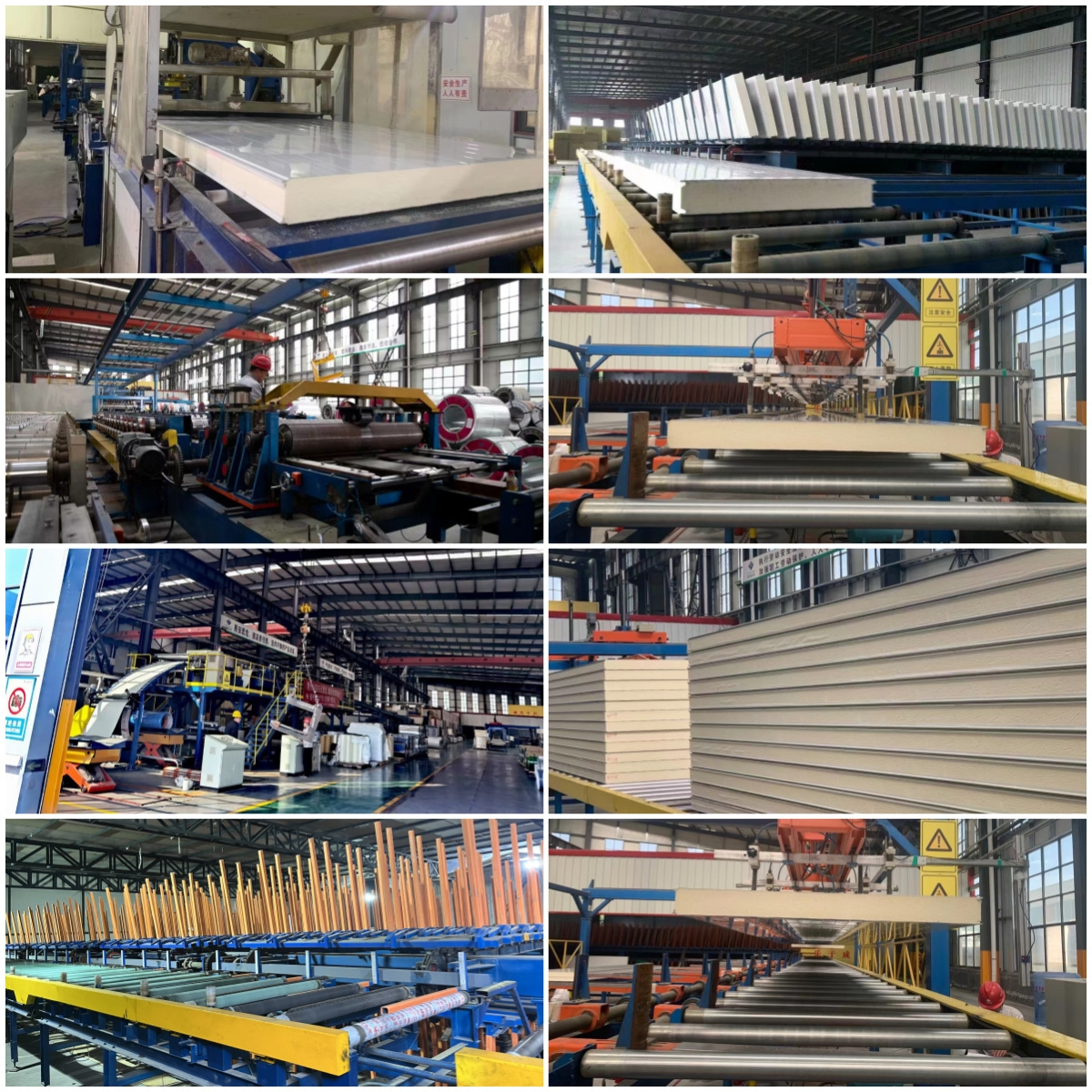

Factory production live shooting video

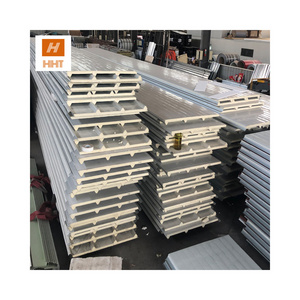

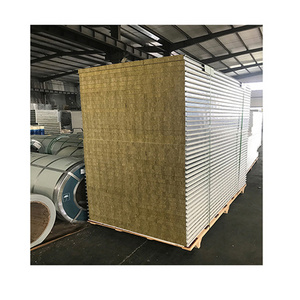

Products Show

Packing & Delivery

Hot Searches