- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

15000*5000*6000mm

-

Weight:

-

3000 kg

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Feed Production Line

-

Keywords1:

-

manufacturing plant for animal feed

-

Keywords 2:

-

feed pellet making line equipment

-

Application:

-

Make Animal Feed

-

Function:

-

Making Feed Pellt

-

Capacity:

-

1-10TPH

-

Raw material:

-

grains, grass, straw.etc

-

Pellet diameter:

-

1.5/22.5/3/3.5/4/6/8/10mm

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Animal Poultry Livestock Feeding

Quick Details

-

Max. Capacity:

-

15 ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GEB

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

15000*5000*6000mm

-

Weight:

-

3000 kg

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Feed Production Line

-

Keywords1:

-

manufacturing plant for animal feed

-

Keywords 2:

-

feed pellet making line equipment

-

Application:

-

Make Animal Feed

-

Function:

-

Making Feed Pellt

-

Capacity:

-

1-10TPH

-

Raw material:

-

grains, grass, straw.etc

-

Pellet diameter:

-

1.5/22.5/3/3.5/4/6/8/10mm

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Animal Poultry Livestock Feeding

Product Description

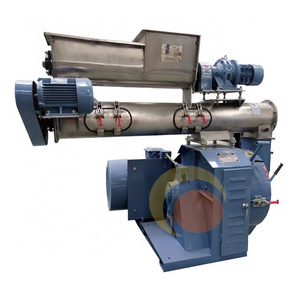

Animal Feed Production Line

This animal feed pellet production line can be used to process livestock and poultry and aquatic feed pellets, especially for

large feed mills and farms. It has good versatility of raw materials and can be used for granulation of various rawmaterials such as corn, sorghum, wheat, beans, and oil seed meal. In addition, the animal feed production plant has the characteristics of low energy consumption, high production efficiency and large profits.

large feed mills and farms. It has good versatility of raw materials and can be used for granulation of various rawmaterials such as corn, sorghum, wheat, beans, and oil seed meal. In addition, the animal feed production plant has the characteristics of low energy consumption, high production efficiency and large profits.

Nutrient loss is very small, the surface of the machined particles is smooth, the hardness is moderate, and the degree of internal maturation is deep. It can also kill pathogenic microorganisms and parasites.

Specification

Title goes here.

It is a small machine that is dry in and out in the flat mode pellet machine. Various additives can be added to the processed pellet feed to ensure the quality of the feed. Due to the dry-in and dry-out, the water content of the pellet feed is less than 12%, which is convenient for storage after sealing. The processed particles are uniform in composition and neat in shape. The thickness of the particles can be divided into: 2, 2.5, 3, 3.5, 4, 5, 6, 7, 8mm, etc. Special models can be customized.

|

product name

|

1 tons per hour feed production line

|

|

Model

|

GEB/1MT

|

|

Capacity

|

1000KG/H

|

|

NW/GW

|

1500KG

|

|

package size

|

1240*540*1000

|

|

power

|

Three phase 15/55/22

|

|

usage

|

Industrial pellet machine line for animal food

|

|

No.

|

Item

|

Model

|

Qty.

|

Power(kw)

|

|

1

|

Hammer mill

|

50-40

|

1

|

22

|

|

2

|

dust collector

|

16 model

|

1

|

|

|

|

|

|

|

|

|

3

|

Self-priming crusher

|

9FQ-510x125

|

1

|

7.5

|

|

4

|

Screw conveyor

|

LS160

|

1

|

2.2

|

|

5

|

Air shut-off device

|

TGFZ-250

|

1

|

0.75

|

|

6

|

Mixer

|

9HWP500

|

1

|

7.5

|

|

7

|

Screw conveyor

|

LS220

|

1

|

4

|

|

8

|

Storage Bin

|

1m鲁

|

1

|

|

|

|

|

|

|

|

|

9

|

Feeder

|

LS160

|

1

|

0.75

|

|

10

|

Pellet mill

|

ZLSG400

|

1

|

30

|

|

11

|

Air dryer

|

|

1

|

5.25

|

|

|

|

|

|

|

|

12

|

Belt conveyor

|

QB380

|

1

|

2.2

|

|

13

|

Packing machine

|

DCS50

|

1

|

1.26

|

|

14

|

Electric cabinet

|

|

1

|

|

|

|

|

|

|

|

Raw Materials and Application

Raw materials

Finished pellet

Packing & Delivery

(1) simple packaging.Other in wooden boxes;

(2) Delivery the machine by 20-foot container/40-foot container;

(3)Delivery the machine within 7 days after receiving balance payment

(4)Once the product is sold, if it is not a product quality problem, it cannot be returned or refunded

(2) Delivery the machine by 20-foot container/40-foot container;

(3)Delivery the machine within 7 days after receiving balance payment

(4)Once the product is sold, if it is not a product quality problem, it cannot be returned or refunded

FAQ

Question 1 : Is the pellet machine dry in and out?

Answer: What we usually call dry-in and dry-out means that the raw materials can be processed directly. This is a

misunderstanding. It is not a real dry-in and dry-out, because the raw materials used contain a certain percentage of moisture, as long as the overall humidity is Between 10%-15%, there is no need to add water, and it can be done directly. If the raw materials are very dry, you can spray a little water, a small amount, about 3%-5%, so that it can be formed well and will not affect storage.

Question 2 : Does the pellet machine have any requirements for raw materials?

Answer: Grain materials do not need to be crushed, but forage and straw must be crushed before they can be processed. It is best to use powder materials because the particles made from powder materials are evenly nutritious.

Question 3 : Can we customize our logo/website/company name on Feed pellet machine?

Yes, we offer OEM and ODM service.

Answer: What we usually call dry-in and dry-out means that the raw materials can be processed directly. This is a

misunderstanding. It is not a real dry-in and dry-out, because the raw materials used contain a certain percentage of moisture, as long as the overall humidity is Between 10%-15%, there is no need to add water, and it can be done directly. If the raw materials are very dry, you can spray a little water, a small amount, about 3%-5%, so that it can be formed well and will not affect storage.

Question 2 : Does the pellet machine have any requirements for raw materials?

Answer: Grain materials do not need to be crushed, but forage and straw must be crushed before they can be processed. It is best to use powder materials because the particles made from powder materials are evenly nutritious.

Question 3 : Can we customize our logo/website/company name on Feed pellet machine?

Yes, we offer OEM and ODM service.

Contact Us

Hot Searches