- Product Details

- {{item.text}}

Quick Details

-

model:

-

X RAY COUNTER

-

MOQ:

-

1 Piece

-

Phototube voltage:

-

80KV

-

Phototube current:

-

0.2mA

-

Focus size:

-

35μm

-

Detector size:

-

470mm*470mm*35mm

-

Pixel matrix:

-

3072*3072pixels

-

Voltage:

-

220V 50-60Hz

-

Weight:

-

800KG

Quick Details

-

Place of Origin:

-

China

-

Model Number:

-

X Ray Component Counter

-

Product name:

-

SMT X-ray intelligent counter X Ray Component Counter

-

model:

-

X RAY COUNTER

-

MOQ:

-

1 Piece

-

Phototube voltage:

-

80KV

-

Phototube current:

-

0.2mA

-

Focus size:

-

35μm

-

Detector size:

-

470mm*470mm*35mm

-

Pixel matrix:

-

3072*3072pixels

-

Voltage:

-

220V 50-60Hz

-

Weight:

-

800KG

Product Description

Introduction to PCB X Ray Component Counter

PCB X Ray Component Counter is a high-performance machine that can automatically detect and count electronic components on printed circuit boards. It is widely used in the electronics manufacturing industry for quality control and inspection purposes.

4. Easy-to-use interface: The machine comes with a user-friendly interface that makes it easy to operate. It features a touch screen display that allows users to configure settings and adjust parameters quickly.

5. Accurate measurement: The machine can measure the size and position of the components accurately, ensuring that they meet the required specifications. This feature is particularly important for parts that require precise positioning.

6. Real-time feedback: The machine provides real-time feedback during the inspection process, allowing operators to identify any issues promptly. This feature helps to ensure that the production process runs smoothly and efficiently.

Conclusion

In summary, PCB X Ray Component Counter is an essential tool for the electronics manufacturing industry. Its automatic detection and counting capabilities, combined with its high-speed processing and accurate measurement, make it an ideal solution for quality control and inspection purposes. The machine's user-friendly interface and real-time feedback also contribute to its efficiency and effectiveness in a production environment.

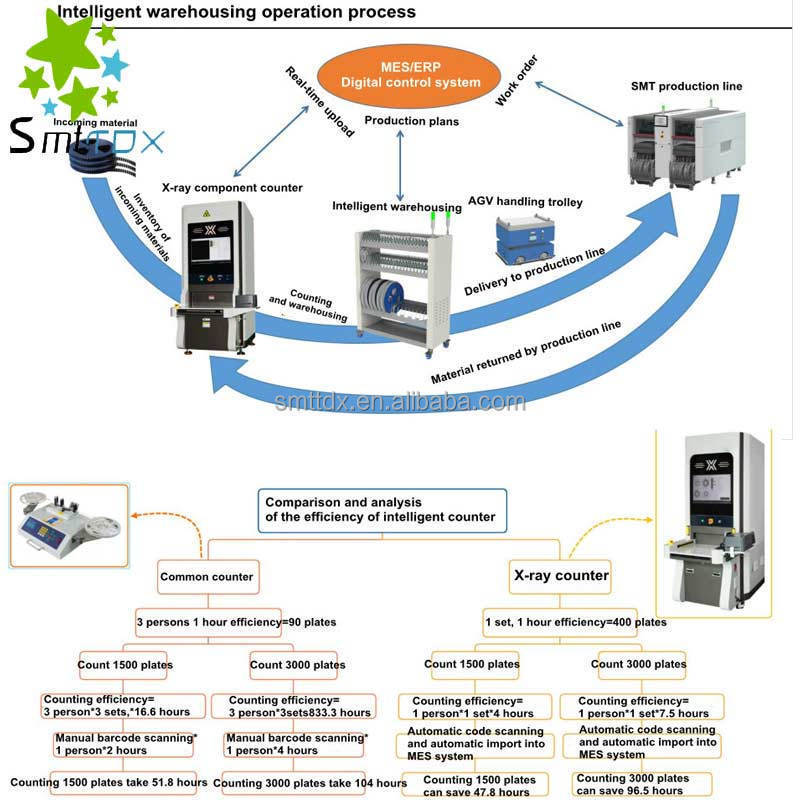

Electronics production machinery SMT Introduction of X-ray intelligent counter

Use requirements: After the direct counting of the X-RAY intelligent counting machine is completed, the result data of the

counting will be uploaded to the digital control system for updating.

And application occasions:

① WO material return ② single LPN inventory ③ initial inventory/double inventory.

Docking scheme and process:

1.Business type initiated by counting machine

The counting machine adds checked items in the operation interface;

High-line mode/WO material return/count sheet count point/single LPN count

① Offline model

No connection with IMS system, direct counting

② WO Material Return

Only applicable to the operation scenario of WO material return:

LPN must be in "push status"

③ Counting sheet count

Applicable to the "custom count" function of IMS;

LPN must be in the "locked status" of the count sheet

④ Single LPN count

Correction of the number of single LPN in the "library" state

2.The point modem calls the IMS interface and transmits the following information to the IMS:

LPN number, business type code

3.LPN verification:

IMS judges whether the current status of LPN is consistent with the selected service type

Verification passed: IMS returns the OK message,

Point data machine starts counting and enters the next step

Verification failed:

IM5 returns NG information, and the counting machine displays in the pop-up box on the operation interface

IMS error message, stop count

4.The counting machine returns the counting result data: LPN number and counting quantity

IMS updates the remaining number of LPN, returns the result information, and prompts the IMS data update result on the computer

interface

Offline mode function introduction

1. The equipment can be used without connecting to the digital control system to realize direct counting in offline mode.

2. The offline mode can realize full automatic counting, full automatic label printing, and full automatic count report

generation.

Offline mode label printing rules

Use requirements: After the direct counting of the X-RAY intelligent counting machine is completed, the result data of the

counting will be uploaded to the digital control system for updating.

And application occasions:

① WO material return ② single LPN inventory ③ initial inventory/double inventory.

Docking scheme and process:

1.Business type initiated by counting machine

The counting machine adds checked items in the operation interface;

High-line mode/WO material return/count sheet count point/single LPN count

① Offline model

No connection with IMS system, direct counting

② WO Material Return

Only applicable to the operation scenario of WO material return:

LPN must be in "push status"

③ Counting sheet count

Applicable to the "custom count" function of IMS;

LPN must be in the "locked status" of the count sheet

④ Single LPN count

Correction of the number of single LPN in the "library" state

2.The point modem calls the IMS interface and transmits the following information to the IMS:

LPN number, business type code

3.LPN verification:

IMS judges whether the current status of LPN is consistent with the selected service type

Verification passed: IMS returns the OK message,

Point data machine starts counting and enters the next step

Verification failed:

IM5 returns NG information, and the counting machine displays in the pop-up box on the operation interface

IMS error message, stop count

4.The counting machine returns the counting result data: LPN number and counting quantity

IMS updates the remaining number of LPN, returns the result information, and prompts the IMS data update result on the computer

interface

Offline mode function introduction

1. The equipment can be used without connecting to the digital control system to realize direct counting in offline mode.

2. The offline mode can realize full automatic counting, full automatic label printing, and full automatic count report

generation.

Offline mode label printing rules

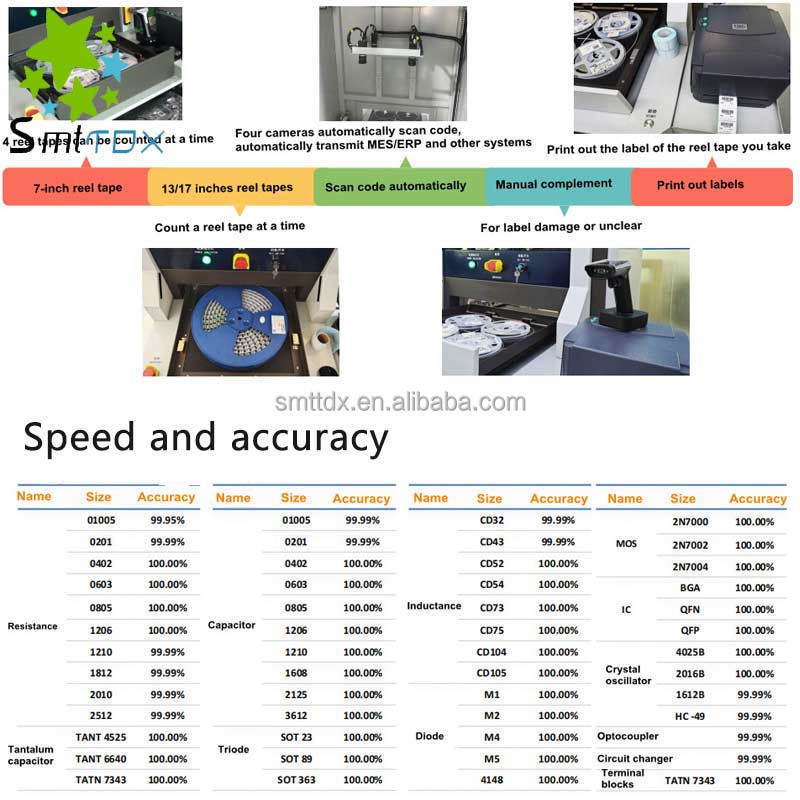

Speed and accuracy

1. X-RAY intelligent counting machine can cooperate with SMT tail stock counting and improve intelligent storage:

2. Four trays of materials can be counted at the same time, which can take only 8s at the fastest. A single equipment can save

5-7 people;

3. Make tailing inventory and material storage more efficient, more secure and more data-based management;

4. For non-conventional materials with inaccurate points, provide model algorithm optimization and update, which can be

optimized within 24 hours;

5. Up to now, the counting time and accuracy of materials of each size are as follows:

2. Four trays of materials can be counted at the same time, which can take only 8s at the fastest. A single equipment can save

5-7 people;

3. Make tailing inventory and material storage more efficient, more secure and more data-based management;

4. For non-conventional materials with inaccurate points, provide model algorithm optimization and update, which can be

optimized within 24 hours;

5. Up to now, the counting time and accuracy of materials of each size are as follows:

Specification

|

Weight (KG)

|

800

|

|

Showroom Location

|

United States, France, Germany

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

X-ray intelligent counter

|

|

Place of Origin

|

China

|

|

Model Number

|

X-ray intelligent counter

|

|

Warranty

|

1 Year

|

|

Product name

|

SMT Introduction of X-ray intelligent counter

|

|

model

|

X RAY COUNTER

|

|

MOQ

|

1 Piece

|

|

Phototube voltage

|

80KV

|

|

Phototube current

|

0.2mA

|

|

Focus size

|

35μm

|

|

Detector size

|

470mm*470mm*35mm

|

|

Pixel matrix

|

3072*3072pixels

|

|

Voltage

|

220V 50-60Hz

|

|

Weight

|

800KG

|

Packing & Delivery

CARTON BOX

Hot Searches