- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

YX-SPRI-ZXX-0052

-

Service:

-

OEM ODM Custom Service

-

MOQ:

-

1000 PCS

-

Size:

-

Customer's Requst

-

Type:

-

Gas Charged

-

Color:

-

Sliver

-

OEM:

-

Offered

-

Finish:

-

Color Zinc Plating

-

Payment term:

-

TT.Western Union.Paypal.Credit Card

-

Quality control:

-

100%inspection

-

Certificate:

-

ISO9001/ROHS/IATF16949

Quick Details

-

Style:

-

Cylinder

-

Material:

-

Metal+Plastic

-

Use:

-

Automobile;Auto;Car

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

YX-SPRI-ZXX-0052

-

Service:

-

OEM ODM Custom Service

-

MOQ:

-

1000 PCS

-

Size:

-

Customer's Requst

-

Type:

-

Gas Charged

-

Color:

-

Sliver

-

OEM:

-

Offered

-

Finish:

-

Color Zinc Plating

-

Payment term:

-

TT.Western Union.Paypal.Credit Card

-

Quality control:

-

100%inspection

-

Certificate:

-

ISO9001/ROHS/IATF16949

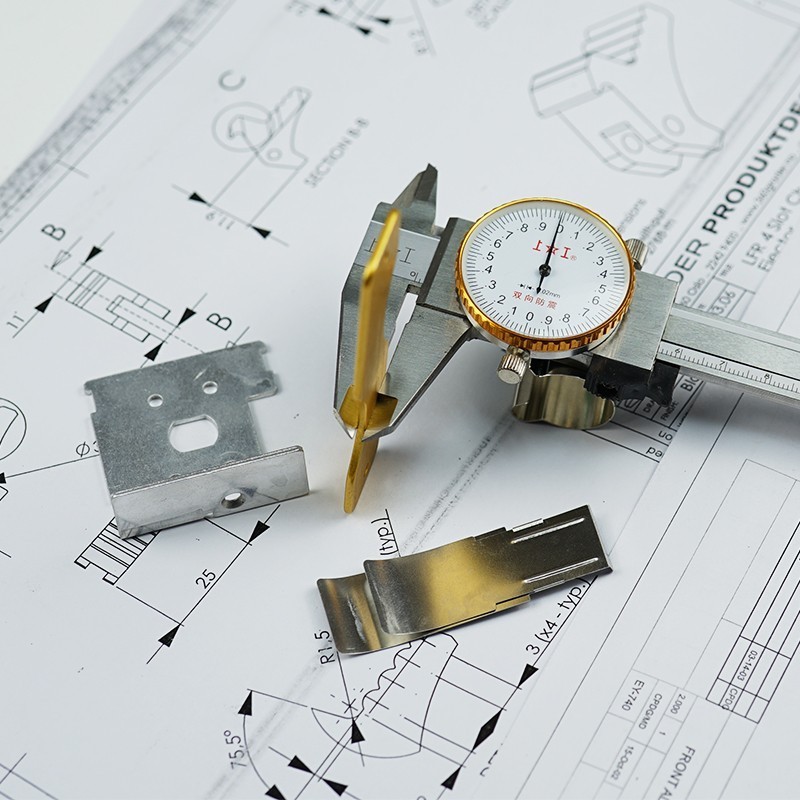

Designing

Our team could design according to your detail requirements or concepts. Or we will suggest to improve when have issues before producing.

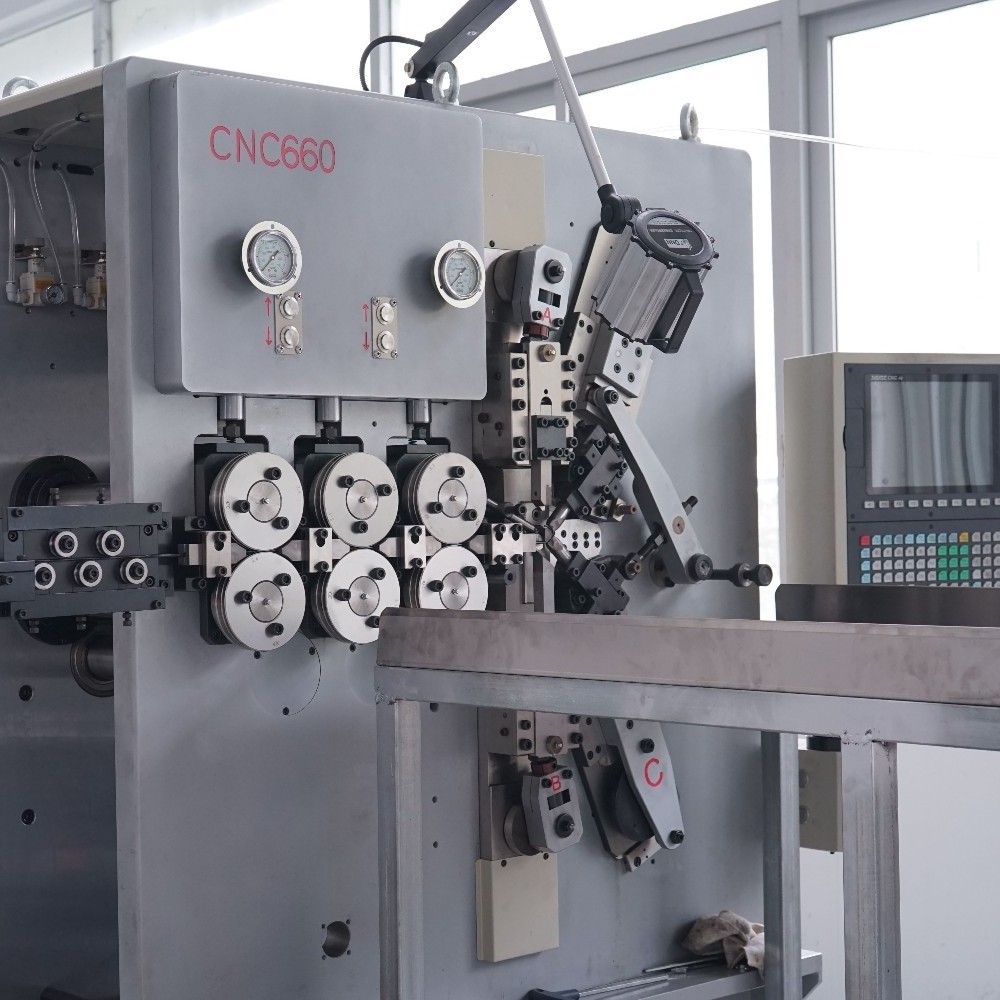

Manufacturing

After designing, we could produce the parts separately, from prototyping to testing samples, and improve according to your testing feedback.

Assembling

After every details confirmed, and the finished of separated parts, we will assemble them together, test with reports, and prepare for shipping.

Why choose us:

1.Provide

OEM/ODM

and

assembling service

,since 2000

2.

One-stop purchasing service

:Stamping parts,CNC milling parts,CNC turning parts,auto lathe parts,Springs,Shafts,fastener etc

3.

Certification

:ROHS,HE,ISO/9001:2008 and TS16949

4.With

Professional Engineers Team

can help you for projects research and development(R&D). Meanwhile we can suggest the most suitable material and manufacturing progresses for your products to save the cost and ensure the quality and usage.

5.

100% inspection

before delivery

6.Our main goal is

TOTAL CUSTOMER SATISFACTION

while making your job easy!

|

Product

|

Customized

|

|

|

||

|

Raw material

|

Aluminum Alloy

|

5052 /6061/ 6063 / 2017 / 7075 / etc.

|

|

||

|

|

Brass Alloy

|

3602 / 2604 / H59 / H62 / etc.

|

|

||

|

|

Stainless Steel Alloy:

|

303 / 304 / 316 / 412 / etc.

|

|

||

|

|

Steel Alloy

|

Carbon Steel / Die Steel / Spring Steel / Cold Rolled Steel etc.

|

|

||

|

|

Plastic

|

POM / PEEK / Nylon / PMMA / PVC / ABS / HDPE / etc.

|

|

||

|

|

Other Materials

|

Titanium / Bronze / Copper / etc.

|

|

||

|

|

We handle many other type of materials.

Please contact us if your required material is not listed above. |

|

|

||

|

Surface treatment

|

Anodizing, Electroplating, Deburring, Powder coating, Zinc plating, Brushed, Polishing, Oil /Baking Paint, Electrophoresis, Sand Blasting Painting, etc

|

|

|

||

|

Dimension

|

According to customer's drawings or samples

|

|

|

||

|

Precision

|

0.01-0.05mm, or according to ISO 2768 or customer's requirements

|

|

|

||

|

Production process

|

Purchasing raw material → do Inspection on raw material (IQC) → make samples → Inspection samples(QC and engineer) → Sample approved by customer → Mass production(LQC,PQC) → Surface finish (IQC) → Packing (FQC) / Make Delivery(FQC).

|

|

|

||

|

Certification

|

ROHS, HE, ISO9000-2008, IGS, IATF16949 etc.

|

|

|

||

|

Application

|

Electrical, Mechanical equipment, Furniture, Daily commodity.

|

|

|

||

|

Packaging

|

PP bag inside with shipping protection cases or customized

|

|

|

||

|

Delivery time

|

Normally ready goods and shipment with 10-25 working days

( BUT MAINLY depend on specific situation)

|

|

|

||

|

Payment terms

|

FOB shenzhen Port. 30% deposit by T / T, 70% before all shipment.

|

|

|

||

Machining process

◥◤

2. Outer Packaging : carton, wooden case, pallet etc.

3. According to customers' requirement.

ShuangXin Industry Co.Ltd

is mainly specialized in the manufacturing of metal / plastic hardware products, which are widely used in electronics, electrical appliances, furniture, construction, toys, automotive /motorcycle, machinery, kitchen home appliances and other fields. Now our export sales turnover rises by 30% steadily each year.

Our Workshop

Shuangxin

have 8500 square meters and

more than 500 sets of high-precision equipment

for stamping parts, stamping dies, CNC milling parts, CNC lathes/turned parts and automatic lathe parts, springs, screws, rivets, shafts, etc. And a variety of custom hardware parts processing and surface treatment. At the same time, it has

more than 200 professional technicians and service teams

to guarantee

on-time delivery

and qualified products

.

A

professional QC team

with complete QC equipment ensures that products are qualified from raw materials to final products. ISO9001 / 2008, TS16949 and Michelin's social responsibility factory audit passed.

Products Range

◥◤

Measuring Tools

◥◤

Inspection equipments

◥◤

Our Team

◥◤

1. Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

2. Q: How can I get the sample? What's the lead time?

A: Normally will be send in 7days. If need to open new Model, need another 10-15days more.

3. Q: What's the lead time for mass production?

A: 20-25days after down payment confirmed, can be negotiable.

4. Q: How does your factory control product quality?

A: ISO9001: 2008, ISO / TS16949 Certificated, independent quality control team with 16 inspectors in our factory. Third party certificated and factory audit accepted. Third party quality control accepted.

5. Q: What about the payment terms?

A: FOB shenzhen Port. 30% deposit by T / T, 70% before all shipment.

What details is in need for a quote ?

(1)Offical drawing or Draft & Scretch or picture with dimension details.

(2) Raw Material (see to above product basic inforamtion table )

(3) Surface finish (see to above product basic inforamtion table )

(4) Quantity for one order and one year.