- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LENO

-

Liquid Flow Rate:

-

1.9

-

Maximum Working Pressure:

-

2.5Mpa

-

Weight:

-

KG

-

Dimension(L*W*H):

-

customized

-

Product Name:

-

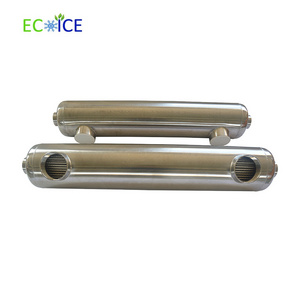

stainless steel tube piper heat exchanger

-

Material:

-

SS304,SS316

-

sealing:

-

EPDM,PTFE

-

Heat exchanger type:

-

Tube heater exchanger

-

heat exchanger square:

-

0.1-20Square

-

Feature:

-

heating and cooling

-

working temperature:

-

20-147celsuis degree

-

flow:

-

0-30T

-

Max fin number:

-

300

-

connection size:

-

6mm-25mm

Quick Details

-

Structure:

-

Tube Heat Exchanger

-

Voltage:

-

110V-480V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LENO

-

Liquid Flow Rate:

-

1.9

-

Maximum Working Pressure:

-

2.5Mpa

-

Weight:

-

KG

-

Dimension(L*W*H):

-

customized

-

Product Name:

-

stainless steel tube piper heat exchanger

-

Material:

-

SS304,SS316

-

sealing:

-

EPDM,PTFE

-

Heat exchanger type:

-

Tube heater exchanger

-

heat exchanger square:

-

0.1-20Square

-

Feature:

-

heating and cooling

-

working temperature:

-

20-147celsuis degree

-

flow:

-

0-30T

-

Max fin number:

-

300

-

connection size:

-

6mm-25mm

Products Description

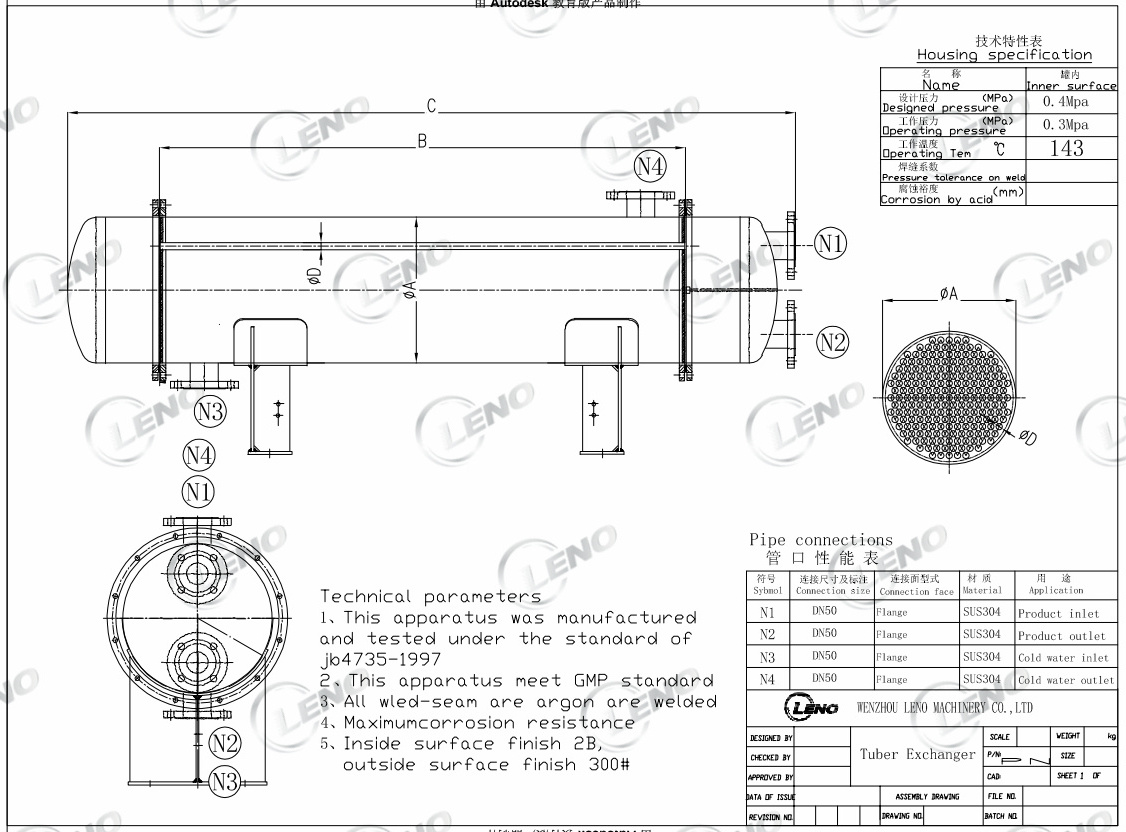

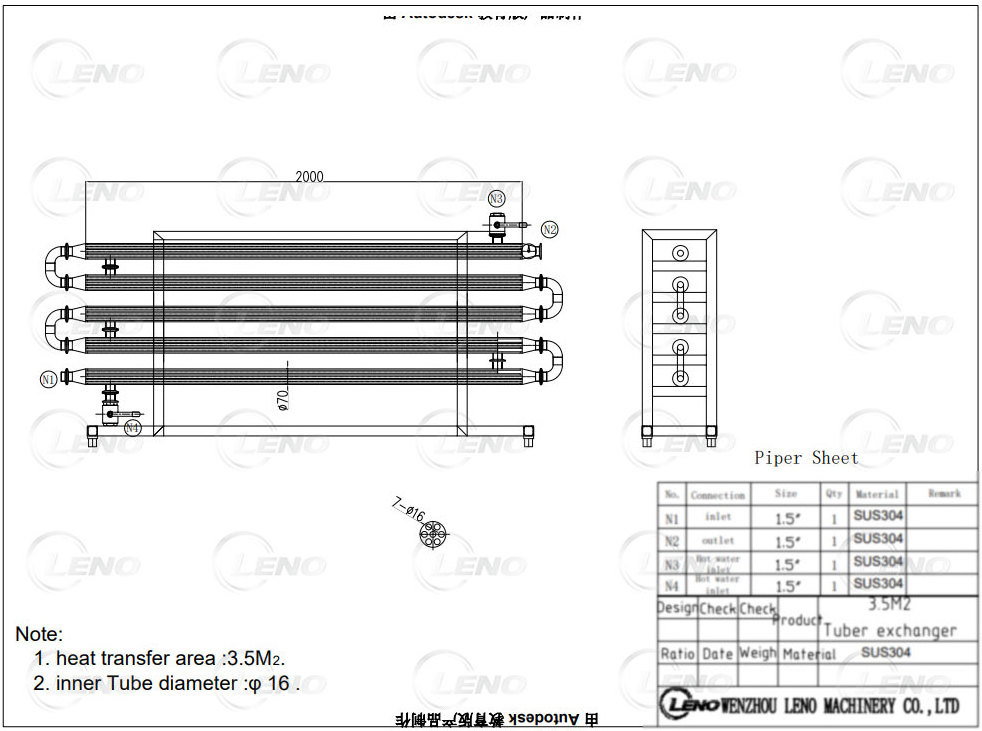

LENO tube heat exchanger is a type of heat exchanger that consists of a series of tubes through which a fluid flows and exchanges heat with another fluid or gas. The basic structure of a tube heat exchanger typically includes:

1:Shell: The outer casing that encloses the tubes and contains the fluid that is being heated or cooled.

2:Tube bundle: The group of tubes that run through the shell and through which the fluid flows.

3:Tube sheets: The plates that are used to hold the tubes in place at both ends of the shell.

4:Baffles: These are plates that are placed inside the shell to direct the flow of the fluid around the tubes. The baffles help to increase the heat transfer efficiency by creating turbulence in the fluid flow.

5:Inlet and outlet ports: These are the openings in the shell where the fluid enters and exits the heat exchanger.

6:Support structure: This includes any additional supports or brackets that are needed to hold the heat exchanger in place.

The design of a tube heat exchanger can vary depending on the specific application and the fluids being used. However, the basic structure outlined above is common to most tube heat exchangers.

1:Shell: The outer casing that encloses the tubes and contains the fluid that is being heated or cooled.

2:Tube bundle: The group of tubes that run through the shell and through which the fluid flows.

3:Tube sheets: The plates that are used to hold the tubes in place at both ends of the shell.

4:Baffles: These are plates that are placed inside the shell to direct the flow of the fluid around the tubes. The baffles help to increase the heat transfer efficiency by creating turbulence in the fluid flow.

5:Inlet and outlet ports: These are the openings in the shell where the fluid enters and exits the heat exchanger.

6:Support structure: This includes any additional supports or brackets that are needed to hold the heat exchanger in place.

The design of a tube heat exchanger can vary depending on the specific application and the fluids being used. However, the basic structure outlined above is common to most tube heat exchangers.

|

Profile/type

|

SS304 SS316L Water Treatment Stainless Steel Milk Strainer

|

|

|

|

||||

|

material

|

SS304 or SS316L

|

|

|

|

||||

|

Capacity

|

0-100T/H (Customized)

|

|

|

|

||||

|

Working Pressure

|

0-8bar

|

|

|

|

||||

|

Design pressure

|

10bar

|

|

|

|

||||

|

cartridges material

|

PP(cartridges)

|

|

stainless steel (mesh)

|

|

||||

|

Temperature

|

0-135°C

|

|

|

|

||||

|

cartridges micron

|

0-400mesh

|

|

|

|

||||

|

gasket

|

EPDM

|

PTFE

|

VITON

|

SILICON

|

||||

|

cartidges type

|

non standard

|

|

|

|

||||

|

We can customize the equipment according to customers' requirment.

|

|

|

|

|

||||

Product Paramenters

|

Model

|

Product capacity (T/H)

|

Working temperature (°C)

|

Heat exchanger area(m2)

|

The Diameter of Pipe(mm)

|

||||

|

LEX-1

|

1

|

20-147°C

(According to customer requirements) |

0.1~20M2

|

Φ6/Φ9/Φ12/Φ16/Φ19/Φ25mm

|

||||

|

LEX-2

|

2

|

|

|

|

||||

|

LEX-3

|

3

|

|

|

|

||||

|

LEX-5

|

5

|

|

|

|

||||

|

LEX-8

|

8

|

|

|

|

||||

|

LEX-10

|

10

|

|

|

|

||||

|

LEX-15

|

15

|

|

|

|

||||

|

LEX-20

|

20

|

|

|

|

||||

|

LEX-30

|

30

|

|

|

|

||||

|

we can design drawing according to your requirements.

|

|

|

|

|

||||

Product Images

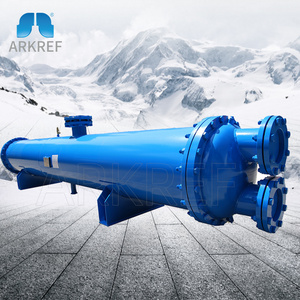

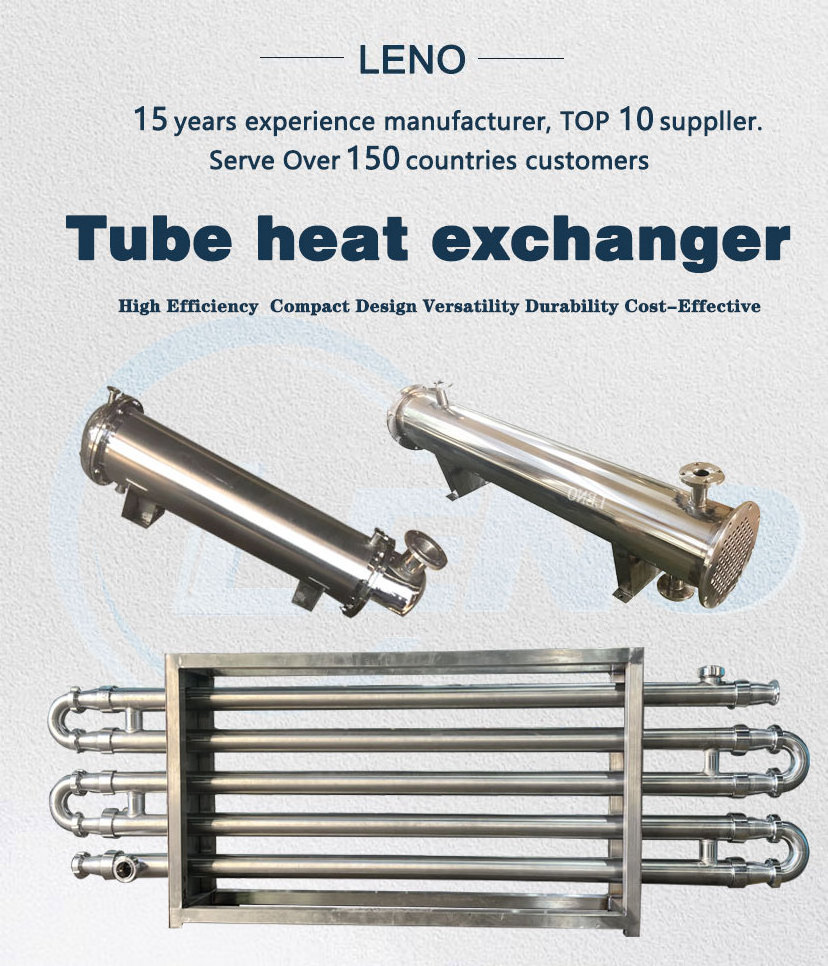

Food grade stainless steel sanitary shell and tube heat exchangers have several advantages, including:

1. High Efficiency: Tube heat exchangers have a large surface area, allowing for efficient heat transfer between two fluids. This results in a high heat transfer rate, making them suitable for a wide range of applications.

2. Compact Design: Tube heat exchangers have a compact design, allowing them to be used in applications where space is limited.They are also easy to install and maintain, making them a popular choice for many industries.

1. High Efficiency: Tube heat exchangers have a large surface area, allowing for efficient heat transfer between two fluids. This results in a high heat transfer rate, making them suitable for a wide range of applications.

2. Compact Design: Tube heat exchangers have a compact design, allowing them to be used in applications where space is limited.They are also easy to install and maintain, making them a popular choice for many industries.

3. Versatility: Tube heat exchangers can be used with a variety of fluids, including gases, liquids, and even solids. This makes them versatile and suitable for a wide range of applications, including chemical processing, refrigeration, and power generation.

4. Durability: Tube heat exchangers are typically made of durable materials such as stainless steel, copper, or titanium, which can withstand high temperatures and corrosive environments. This makes them a reliable and long-lasting option for many industries.

5.Cost-Effective: Tube heat exchangers are often more cost-effective than other types of heat exchangers due to their simple design and ease of installation and maintenance. They are also energy-efficient, which can help reduce operating costs over time.

4. Durability: Tube heat exchangers are typically made of durable materials such as stainless steel, copper, or titanium, which can withstand high temperatures and corrosive environments. This makes them a reliable and long-lasting option for many industries.

5.Cost-Effective: Tube heat exchangers are often more cost-effective than other types of heat exchangers due to their simple design and ease of installation and maintenance. They are also energy-efficient, which can help reduce operating costs over time.

Hot Searches