- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/450V

-

Power:

-

200-700kw

-

Dimension(L*W*H):

-

Customize

-

Certification:

-

ISO9001, ISO9001-2008

-

Speed of draw up widthness:

-

250 and 300mm

-

Induction furnace:

-

triple furnaces combined

-

Size of belt:

-

8mm and 10mm

-

Speed of draw up thickness:

-

Adjustable

-

Pull picth:

-

Adjustable

-

Type of taking up:

-

curvature auto adjustment

-

Driving type:

-

double servo motor

-

Each strand of copper belt:

-

more than 2 tons

-

Weight:

-

Customize

Quick Details

-

Place of Origin:

-

Henan, China

-

Machine Type:

-

SYLZ

-

Brand Name:

-

benteng

-

Voltage:

-

220V/380V/450V

-

Power:

-

200-700kw

-

Dimension(L*W*H):

-

Customize

-

Certification:

-

ISO9001, ISO9001-2008

-

Speed of draw up widthness:

-

250 and 300mm

-

Induction furnace:

-

triple furnaces combined

-

Size of belt:

-

8mm and 10mm

-

Speed of draw up thickness:

-

Adjustable

-

Pull picth:

-

Adjustable

-

Type of taking up:

-

curvature auto adjustment

-

Driving type:

-

double servo motor

-

Each strand of copper belt:

-

more than 2 tons

-

Weight:

-

Customize

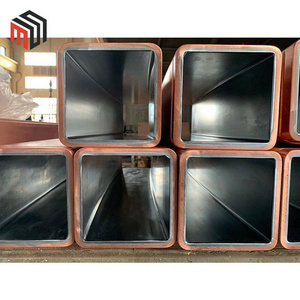

Copper conductor sheets is used for producing bright and long oxygen-free copper rod,copper row,

copper tube,flat copper bar.This machine can directly produce different specifications of copper row and other special shaped copper material continuously from electrolytic copper.

Advantages of our machine

1.Control the oxygen content of copper belt to eliminate the hollow core technology;

2.Low energy consumption, energy consumption in a single tonne 20% lower than that of other domestic similar devices ;

3.Removable sensors, flexible maintenance, short repair time;

4.Computer control, servo drive system, man-machine conversation interface;

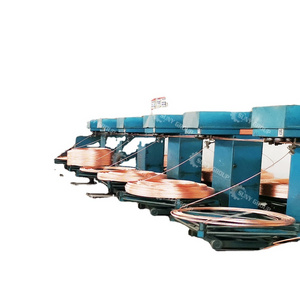

5.Automatic controlling take-up, more than 2 tons single rolling weight;

6.The highest grade of the heat-resistant furnace material.

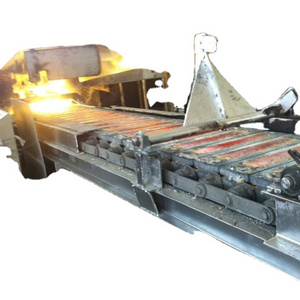

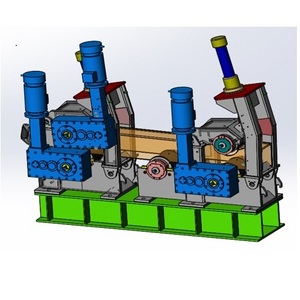

The technological process of this upcast continuous casting machine for oxygen-free copper belt is:Electrolytic copper plate (cathode copper)→melting furnace→transition

warehouse→holding furnace→crystallizer→ dragger→Automatic speed device→automatic winding machine→for sale or deep processing.

Cathode Copper Plate

Induction Furnace

Upcasting Device

Electrical Control System

Operation Desk

Take-up Unit

Xinxiang Pentium Electric Equipment Co., Ltd. is a high-tech enterprise mainly engaged in the manufacture of non-ferrous metal smelting, processing equipment design and manufacturing, and technical services. The company has long-term talents for design and development, a sound quality assurance system and a first-class staff team. In the past few years, we have taken advantage of our talents and have our own core technology in production equipment and technology. On the basis of drawing on and absorbing the equipment and technology of copper processing industry at home and abroad, we have made outstanding achievements and product quality through unremitting efforts and exploration. Praised by users, providing a large number of services for the national wire and cable industry.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally we are 70 days delivery.

Q: Do you provide samples ? is it free or extra ?

A: No,Because we sell the product mechanically, we cannot provide samples.

Q: What is your terms of payment ?

A:

*

Professional solution according to your and your customer's requirements.

* 11 years copper machine manufacturing experience and state-of-the-art technology with Benteng.

* Never about the maintainace, Benteng offers you mature after-sale services and spare parts.