- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

2500mm*1200mm*1500mm

-

Weight:

-

2500 kg

-

Feeding width:

-

1200mm or customer's need

-

Product name:

-

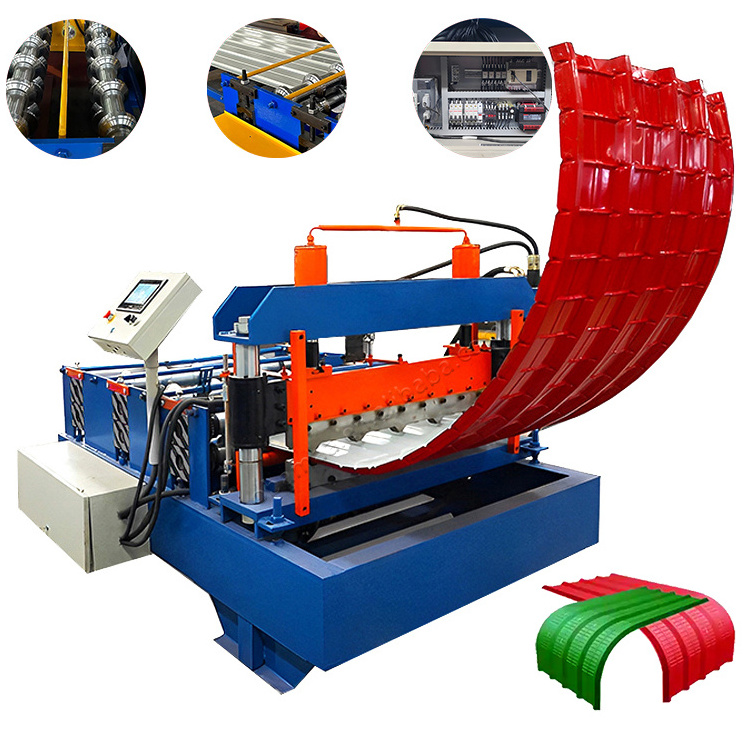

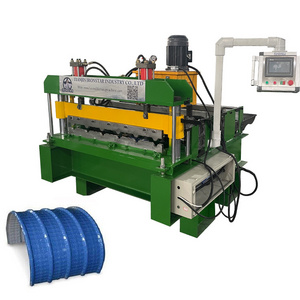

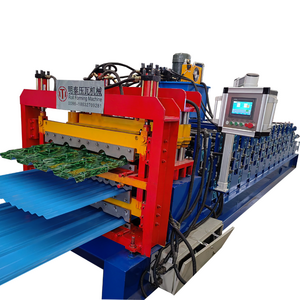

Arched Corrugated roofing sheet curving machine

-

Number of forming rollers:

-

3-4 rows

-

Main frame:

-

300 H steel

-

Thickness of formed steel:

-

0.3-0.8mm

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Motor power:

-

3KW

-

Control system:

-

PLC(imported Brand)

-

Forming speed:

-

8000-10000mm/min

-

Cutting type:

-

Hydraulic Cutting

Quick Details

-

Type:

-

Arching Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10-20 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

2500mm*1200mm*1500mm

-

Weight:

-

2500 kg

-

Feeding width:

-

1200mm or customer's need

-

Product name:

-

Arched Corrugated roofing sheet curving machine

-

Number of forming rollers:

-

3-4 rows

-

Main frame:

-

300 H steel

-

Thickness of formed steel:

-

0.3-0.8mm

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Motor power:

-

3KW

-

Control system:

-

PLC(imported Brand)

-

Forming speed:

-

8000-10000mm/min

-

Cutting type:

-

Hydraulic Cutting

Products Description

Hydraulic Roof Curving Machine

The hydraulic roof sheet curving machine also named roof panel crimping machine is an auxiliary device for a roof panel roll forming machine. It is used for curving the roofing sheet to a required shape with different radius. Generally, customer will buy a roofing sheet roll forming machine with this crimping machine. The crimping machine used to curve the sheet which produced by the roofing sheet roll forming machine. Normally the panel thickness is 0.3-0.8mm with normal galvanized steel or colored coil.

Specification

|

Hydraulic Roof Curving Machine

|

|

|

||

|

SN

|

Item

|

Specification

|

||

|

1

|

Machinable Material

|

Color steel plate, Steel plate, Galvanized sheet and so an

|

||

|

2

|

Thickness(MM)

|

0.3-0.8 or According To Your Requirment

|

||

|

3

|

Yield Strength

|

250 - 350 Mpa / 350-550Mpa

|

||

|

4

|

Tensil Stress

|

350 Mpa-550 Mpa

|

||

|

5

|

Panel Width

|

As Per The Panel With Comes From Roll Forming Machine

|

||

|

6

|

Feeding Way

|

Servo Feeding or Step Motor Feeding

|

||

|

7

|

Curving System

|

Hydraulic

|

||

|

8

|

Material Of Punching Mould

|

40Cr, Surface Quenching And Nitrifying

|

||

|

9

|

Power Supply

|

380V 50Hz 3ph Or According To Your Requirment

|

||

|

10

|

Machine Color

|

Industrial Blue Or According To Your Requirment

|

||

|

11

|

Machine size

|

2500mm*1200mm*1500mm

|

||

|

12

|

Number of forming rollers

|

3-4 rows

|

||

|

13

|

Weight

|

About 2500KG

|

||

|

14

|

Motor power

|

3KW

|

||

Product Details

Fully automatic computer operation, easy to use, convenient and responsive.

The frame structure is welded with carbon steel plates, which has a long service life.

Low noise operation and short flattening time.

Good bearing capacity and easy operation.

Carefully selecting materials is the key to making good products.

On demand production, welcome to customize with pictures.

Glazed Type

Roll Forming Sheet

Corrugated Type Roll Forming Sheet

IBR Type Roll Forming Sheet

Roofing sheet has many different shapes,usually different countries have its own popular design ,we can customize the machine as customers’ demand.

Q1. How do I choose the right machine for me?

1. A machine doesn't just provide a few photos to prove what they can produce .

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You did not display the product I need. Can you produce it?

Our engineers have studied at well-known European companies and have significant advantages in mechanical design, research and development, and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 20 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate,and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, to be a service company that you have the strength to guarantee.

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Generally speaking, the machine takes about 20 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate,and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, to be a service company that you have the strength to guarantee.

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Hot Searches