- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUSSMAN

-

Voltage:

-

380V or as request

-

Dimension(L*W*H):

-

5*1*1.2m

-

Weight:

-

3000 kg

-

Marketing Type:

-

New Product 2024

-

Name:

-

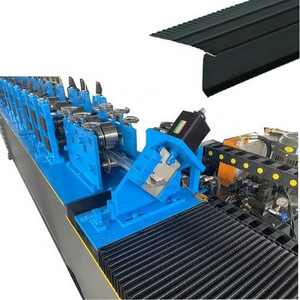

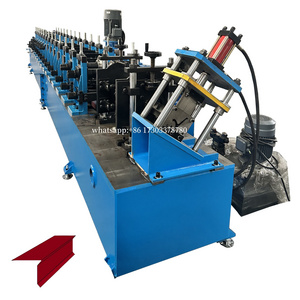

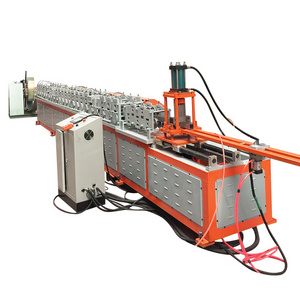

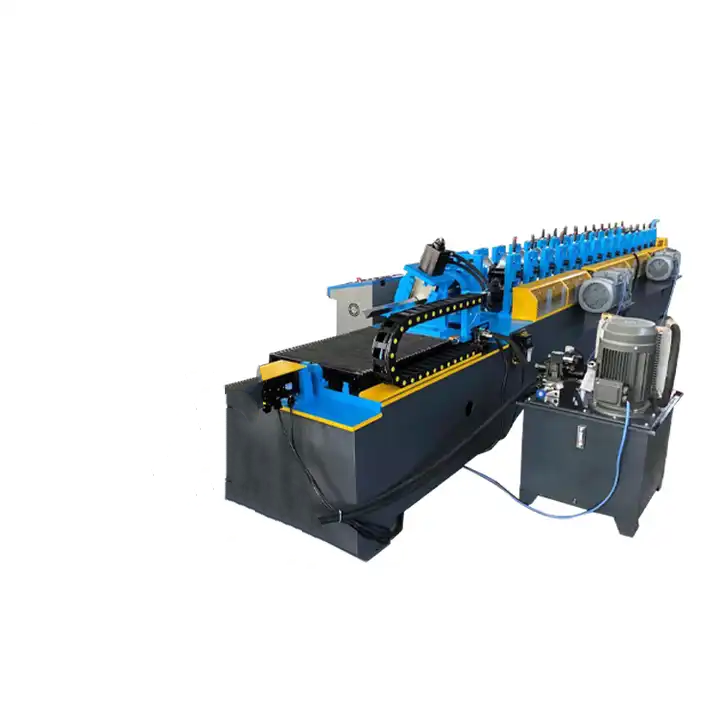

Trim edge making machine dripe edge roll forming machine

-

Material Thickness:

-

0.3-0.8mm galvanized steel

-

Roller Station:

-

About 16 stations

-

Working Speed:

-

0-45m/min

-

Roll Material:

-

45# high grade steel

-

Shaft Material:

-

45# high grade steel

-

Cutting Blade Material:

-

Cr 12 high grade steel

-

Cutting System:

-

Servo following cutting

-

Control System:

-

PLC with touch screen

-

Feature:

-

Steady work condition, low energy consumption

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

0-45m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUSSMAN

-

Voltage:

-

380V or as request

-

Dimension(L*W*H):

-

5*1*1.2m

-

Weight:

-

3000 kg

-

Marketing Type:

-

New Product 2024

-

Name:

-

Trim edge making machine dripe edge roll forming machine

-

Material Thickness:

-

0.3-0.8mm galvanized steel

-

Roller Station:

-

About 16 stations

-

Working Speed:

-

0-45m/min

-

Roll Material:

-

45# high grade steel

-

Shaft Material:

-

45# high grade steel

-

Cutting Blade Material:

-

Cr 12 high grade steel

-

Cutting System:

-

Servo following cutting

-

Control System:

-

PLC with touch screen

-

Feature:

-

Steady work condition, low energy consumption

Product Description

* Raw materials it rolls: Pre-painted steel coils; Aluminum, Galvalum, Galvanized etc

* Material thickness: 0.28-0.8mm (PPGI,GI,GA,PPGA), 0.8-1.2mm(Aluminum)

* Capacity of De-coiler: 5 TONS

* Rollforming stations: 16 stations

* Roller materials: 45# steel with tempering treatment and chrome coating treatment

* Shaft diameter: 70mm

* Safety option: Safety Cover eqiupped

* Cutting: Hydraulic cutoff

* Material of Cutting blade: Cr12 steel

* Control unit: PLC control to ensure the machine to run both automatically and manually.

* Material thickness: 0.28-0.8mm (PPGI,GI,GA,PPGA), 0.8-1.2mm(Aluminum)

* Capacity of De-coiler: 5 TONS

* Rollforming stations: 16 stations

* Roller materials: 45# steel with tempering treatment and chrome coating treatment

* Shaft diameter: 70mm

* Safety option: Safety Cover eqiupped

* Cutting: Hydraulic cutoff

* Material of Cutting blade: Cr12 steel

* Control unit: PLC control to ensure the machine to run both automatically and manually.

Machine List

|

S.N

|

Name

|

Quantity

|

|

1

|

3 ton passive decoiler

|

1 set

|

|

2

|

Main roll forming machine

|

1 set

|

|

3

|

Hydraulic Cutting

|

1 set

|

|

4

|

Control box

|

1 set

|

|

5

|

Output table

|

1 set

|

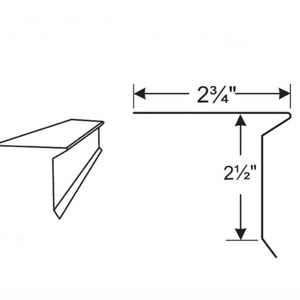

Profile Drawing

Hot Searches