Casting machine casting speed 60-850 mm/min stepless adjustable, with manual descent device. The imported Fuji inverter is used for frequency conversion and speed regulation. The casting machine comprises a hoisting mechanism, a wellhead frame, a tilting mechanism, a hydraulic system, an electronic control system and a water inlet rotating joint.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

35000 KG

-

Product name:

-

billet casting

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Starshine

-

Spare Parts Type:

-

billet casting

-

Weight (KG):

-

35000 KG

-

Product name:

-

billet casting

Products Description

|

Aluminum melting furnace and combustion system

|

|

The bright flame burner specially developed for aluminum alloy melting can reduce the generation of oxide and improve the radiation ability of flame.

|

|

Low burning loss rate, metal burning loss less than 1.7% .

|

|

The furnace body design is reasonable, has the solid structure, is easy to enter the shape to clean, does not have the dead angle.

|

|

Advanced Combustion System design.

|

|

Flue gas heat recovery and utilization, reduce energy consumption, high thermal efficiency, can reach more than 45% .

|

|

To adapt to a variety of fuels, city gas, natural gas, liquefied petroleum gas, diesel, heavy oil can be used.

|

|

Using imported high quality Refractory as lining, the service life is more than three years.

|

|

The temperature of the greenhouse can reach ± 5°C.

|

|

Technical parameters

|

|

|

|

Model

|

Melting Pool Capacity(kg/Al)

|

|

|

QD-YX-15

|

15T

|

|

|

QD-RJ-25

|

25T

|

|

|

QD-RJ-35

|

35T

|

|

|

QD-RJ-50

|

50T

|

|

|

QD-RJ-80

|

80T

|

|

|

QD-RJ-120

|

120T

|

|

Casting system

All parts are designed by Solid Works, finite element analysis and precision NC machining.

The casting platform includes all mould, liquid aluminum distribution system, cooling water distribution system and ingot introduction system. Graphite rings are made of high purity graphite, all Refractory are made of INS140 preform.

The ingot head is of automatic alignment type, and the material of ingot head is cast iron. Four bolts are used to connect the water tank and the ingot base for Integral Assembly and disassembly. The water tank is connected to the tilting arm by four other bolts and can tilt at an angle of 90 °.

Trackless frequency control wire rope drive casting machine

The casting speed of the casting machine is 60-850mm/min, no grade can be adjusted, equipped with manual descent device. Using imported Fuji inverter speed control. The continuous casting machine is composed of a winch mechanism, a casting pit frame, a tilt mechanism, a hydraulic system, an electrical control system and a water inlet rotating joint.

Dynamic display of casting speed

Dynamic display of casting length

Casting water flow dynamic display

Dynamic display of the spindle platform position

Medium-sized 18T winch

Large 25T winch

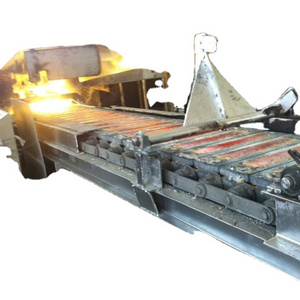

Automatic aluminum bar saw

Automatic aluminum bar saw realizes the movement of translation feeding, electric fixed length, clamping aluminum bar, aluminum bar sawing, finished product discharging, finished product feeding, finished product loading frame, saw pin recycling and packaging, circular transportation sawing and so on. The machine is simple to operate, safe and practical, high production efficiency.

It is made up of blanking frame, conveying pipe, saw-cutting table, blanking mechanism, sizing mechanism, discharging mechanism, aluminum dowel recovery system, finished product loading frame system, hydraulic station and electric control system. Main action driven by hydraulic, stable performance.

Product packaging

PAYMENT

Accept TT, LC

TRANSPORTATION

The product can only be shipped by sea

Product Introduction

We STARSHINE INTL was established in 2015. The company is located in Zhangjiagang Bonded area, specializing in sales and production of aluminum extrusion equipment, billet casting equipment, electrostatic powder coating equipment, anodizing equipment.

Mold factory: Founded in 2002, the company covers an area of 15000 square meters, the existing staff of 102 people, including engineering and technical personnel 30%, the annual mold development and production capacity of about 30000 sets.

Mold factory: Founded in 2002, the company covers an area of 15000 square meters, the existing staff of 102 people, including engineering and technical personnel 30%, the annual mold development and production capacity of about 30000 sets.

Aluminum Extrusion equipment factory: Established in 1996, with more than 27 years of production experience, the company covers an area of 15000 square meters and can produce from 700 T to 6000 T extrusion press.

Electrostatic powder coating machine factory: Founded in 2008, the company covers an area of 38000 square meters. There are more than 280 working staff including 15 experienced coating senior engineers, 6 electrical engineers and 38 engineering technical personnel.

Anodizing and ED machine factory: established in 2011, with 50 employees.

Billet casting equipment machine factory: established in 2005, with 40 employees. We have provided more than 300 sets of aluminum melting/holding furnaces and more than 2000 sets of casting systems worldwide.

Over the years, we STARSHINE INTL have worked hard to establish ourselves as a leading supplier of aluminum extrusion equipment and related technologies. With a focus on quality, innovation and customer satisfaction, we look forward to continuing our journey of growth and expansion in global markets.

FAQ

Q:What is your minimum order quantity, can you send me samples?

A:Our minimum quantity is 1 set, as our product is machinery equipment, it’s difficult to send you samples, however,we can send you catalog, warmly welcome you to come visit our company.

Q:How can i get to your factory?

A:Our factory is near Guangzhou Airport, we can pick you up in the airport.

Q:Can the machine be customized as our need, such as put on our logo?

A:Surely our machine can be customized as your need, Put on your logo is also available.

Q: May I have a testing of the machine to confirm if the machine can satisfy my requirements?

A:Yes, of course . You can send someone to check it in person or we can send a test video.

Q: How long is the warranty of the machines?

A: All the machines we offer one year warranty, during this time, we will send the spare parts for free if the broken caused by the machines themselves. And we offer the whole life support and service with very little cost.

Q:After we placing an order, will you arrange the installation of the machine at present?

A:All the machines will be tested well before delivered, so almost of them can be used directly, also our machine are easy to be installed, if you customer needs our assistance, we will be pleased to arrange the installation, but all the cost will be be charged by you.

Hot Searches