- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Weight (KG):

-

8 KG

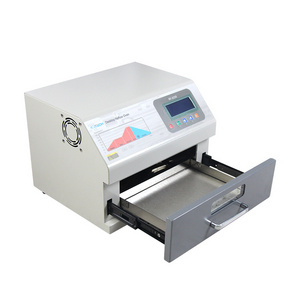

Free shipping infrared ic heater reflow ovens Reflow Oven Machine T962 reflow equipment T-962 Infrared IC Heater

1) T962 is intellegiently controlled by microcomputer can store 8 different profiles.

2) It can be used in leaded and leaded free SMD and bga reworking.

3) Like T962A, T962 can uses a visualable drawer design to hold the PCB in the heating chamber and with lcd display, it allows the soldering process autmatically finished under your eyes.

4) T962 uses a powerful infrared emission and circulation of the hot air flow, so the temperature is being kept very accurate and evenly distributed.

5) T962 can rework PCBA assembly with double side mounted and also can rework very small components,for example CHIP,SOP,PLCC,QFP,BGA etc.It is the ideal rework solution from single runs to on-demand small batch production.

6) T962 has up to 800 watts of energy efficient infrared heating and air circulation to re-flow solder in a large 180×230mm area.

7) The entire soldering process is completes automatically from Preheat, Soak and Reflow through cool- down. Parameters of eight soldering profile are pre-defined.

8) Light weight and a small footprint allows the T962 to be easily bench positioned transported or stored.

9) It also can make underfill mold.

10) Technical details for T962:

Model

T-962

Power Supply

AC 220 V / 110 V; 50 - 60 Hz

Heat Style

infrared radiation + circulating wind

Rated Power

800 W

Cycle Time

1 - 8 min

Control Mode

8 IC temperature waves

Temperature Range (°C )

0-280

Drawer Size (mm)

180 x 235

Size (mm)

310 x 290 x 170

Dimensions (mm)

375 x 240 x 375

Gross Weight (kg)

7

Hot Searches