- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V±10%

-

Power:

-

4000

-

Dimension(L*W*H):

-

5x5x7m

-

Weight (KG):

-

3000

-

After-sales Service Provided:

-

Free spare parts

-

Weight:

-

5t

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Machine Type:

-

Aluminum billet Casting Machine

-

Brand Name:

-

Brassmachines

-

Voltage:

-

380V±10%

-

Power:

-

4000

-

Dimension(L*W*H):

-

5x5x7m

-

Weight (KG):

-

3000

-

After-sales Service Provided:

-

Free spare parts

-

Weight:

-

5t

-

Certification:

-

CE

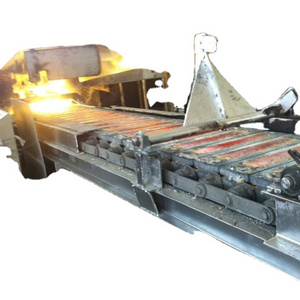

Aluminum Billet Continue Casting Machine Production Line

| Product information |

|

No |

Item |

Qty |

Unit |

Technology |

|

1 |

12T rectangular melting furnace |

1 |

set |

Tall furnace with heat accumulating type burning system, low energy consumption. Continuous melting waste aluminium, casting alloy ingot after degassing in alloy refining |

|

2 |

Aluminum billet casting machine |

1 |

set |

16T trackless inverter control wire rope drive casting machine system (including electric control cabinet) |

|

3 |

Aluminum billet casting mold |

2 |

set |

Φ 152 Φ 178, 1 set for each. |

|

4 |

Pulse cloth bag dust remover |

1 |

set |

Separate chamber stop air pulse injection for dust removal technology. Advantages: strong dust removal capability, high efficiency, low emission concentration, low air leakage rate, low energy consumption, low steel consumption, small size, stable functioning. |

|

5 |

Aluminum ash recycle system |

1 |

set |

The aluminum ash separation and recovery machine is an advanced technology that can quickly recover a machine with a high aluminum content without any fuel. Therefore, instead of the traditional artificial ash method, the aluminum ash separation and recovery machine can be used to separate aluminum and ash at the furnace site, and the aluminum recovery rate is high. |

|

6 |

Liquid channel |

8 |

m |

Made by fired combined ore castable material, nice temperature conservation. Easy for maintenance. |

|

7 |

Filter box |

1 |

set |

Made by fired combined ore castable material, during and easy for handling. 508*508 model: more than 12 tons per hour. |

|

8 |

Online degas system |

1 |

set |

The quality of the aluminum water is further improved by the degassing device, and the pinhole degree is more than one level. |

|

9 |

20T homogenizing furnace |

1 |

set |

Improve the intrinsic quality of aluminum rods by homogenizing furnace |

|

10 |

Cooling tower |

1 |

set |

The high temperature water is cooled through the tower body to reach the process temperature. |

|

11 |

Refining tank |

1 |

set |

The refining agent is uniformly stirred into the aluminum liquid for purification. |

|

12 |

Wire feeder |

1 |

set |

The titanium boron wire is uniformly fed into the aluminum liquid for alloying. |

|

13 |

Cutting saw |

1 |

set |

The aluminum rod head and tail are cut off with a high amount of slag. |

| Product display |

| For more product information, please click | Contact Us >> |

| Hot sale |