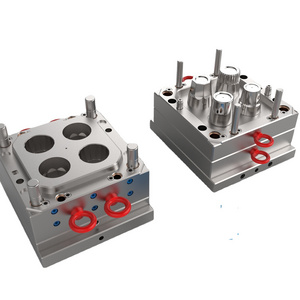

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

yixun001

-

Product:

-

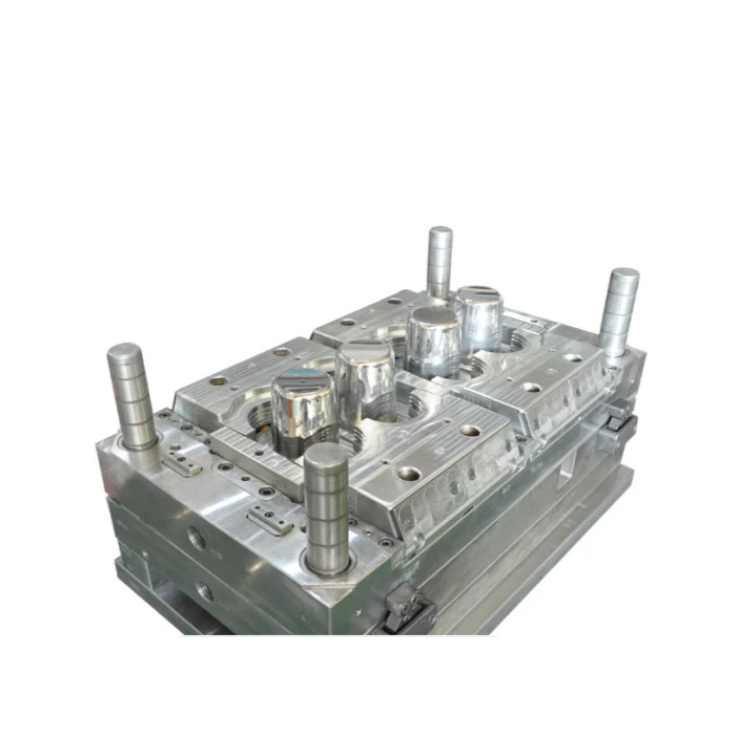

plastic mould

-

Product Name:

-

plastic mould

-

Mould material:

-

UG PROE CATIA SOLIDWORK CAD

-

Mould base:

-

LKM

-

Packing:

-

as your request

-

Certification:

-

ISO9001:2008

-

Mould Life:

-

100k-500k shots

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

-

process:

-

CNC

-

Cavity:

-

Multi

-

Material:

-

Steel

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

yixun

-

Model Number:

-

yixun001

-

Product:

-

plastic mould

-

Product Name:

-

plastic mould

-

Mould material:

-

UG PROE CATIA SOLIDWORK CAD

-

Mould base:

-

LKM

-

Packing:

-

as your request

-

Certification:

-

ISO9001:2008

-

Mould Life:

-

100k-500k shots

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

-

process:

-

CNC

-

Cavity:

-

Multi

-

Material:

-

Steel

|

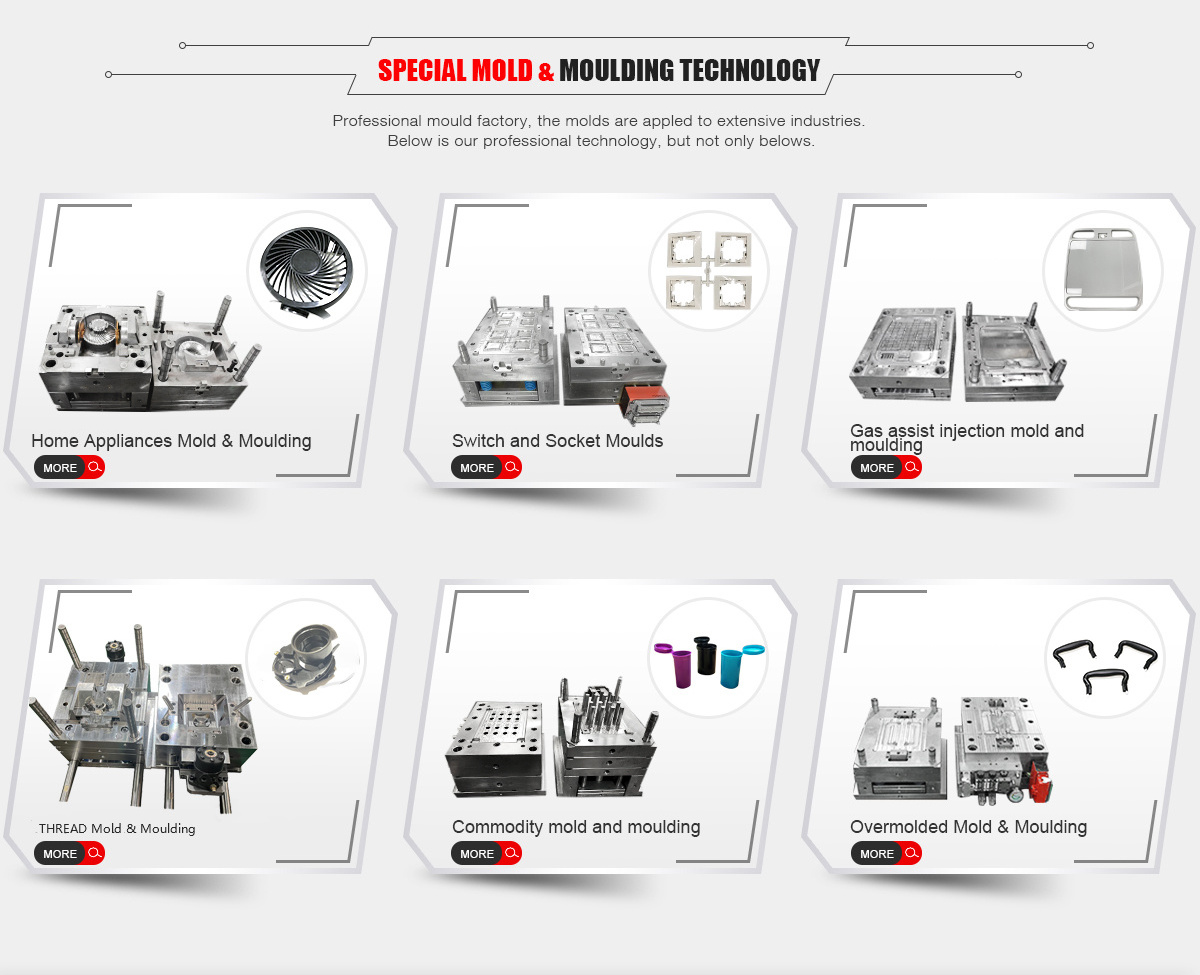

Main Product

|

plastic mold and injection molding manufacture

|

|

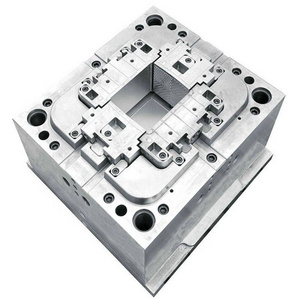

Mould Base

|

LKM,HASCO,etc

|

|

Mould Material

|

s136/2344/718/738/NAK80/p20 etc.

|

|

Moud Precision

|

+/-0.01mm

|

|

Mould Life

|

100k-5000K shots (depend on your requirement)

|

|

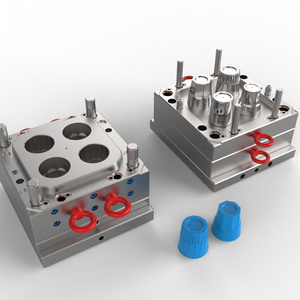

Mould Cavity

|

Single cavity or multi-cavity

|

|

Runner System

|

Hot runner or cold runner

|

|

Gate Type

|

Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc

.

|

|

Equipment

|

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine from 50-818T available.

|

|

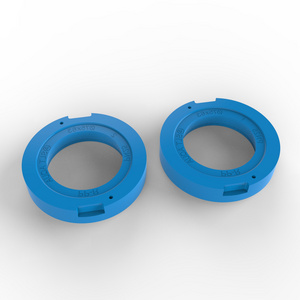

Plastic Material

|

PA6,PA66, ASA, POM, PPS, ABS,ABS+GF,ABS+PC,POM,PP, PE,PC,PMMA(Acrylic),TPE,TPU,PEI,PBT,PTFI

|

|

Metal Material

|

pre-harden steel, heat treatment steel

|

|

Surface Treatment

|

Polishing/smooth,texture/frosted, painting, plating, printing , etc.

|

|

Pls Provide

|

2D/3D drawing, samples

|

|

Quanlity System

|

ISO 9001: 2015

|

|

We Promise

|

All customer-centric, never for short-term profit, and sell long-term benefits

|

Dongguan YIXUN Industrial Co.,Ltd is a high technology company,specializing in many kinds of plastic mold designing,manufacturing and injecting,mainly covering the enclosure and part of medical,gas assisted, electrical products switch and socket ,daily commodity ,transparent parts mould and moulding etc.

YiXun cover area totally 12,000 square meters, 260 employees, 90% of them has experience over 10 years.

YiXun yearly capability is up to 600 sets mold per year, the biggest reach 25 tons.

YiXun adopt the up-to-date design software, such as Auto CAD, UG, Pro/E, Solid Works etc, Mould standards such as DME, HASCO, FUTABA, LKM and so on.

YiXun cover area totally 12,000 square meters, 260 employees, 90% of them has experience over 10 years.

YiXun yearly capability is up to 600 sets mold per year, the biggest reach 25 tons.

YiXun adopt the up-to-date design software, such as Auto CAD, UG, Pro/E, Solid Works etc, Mould standards such as DME, HASCO, FUTABA, LKM and so on.

FAQ

Q: Are you a factory or trading company?

A: YIXUN is plastic mold and injection molding manufacture in Dongguan of China, welcome to visit us.

Q: How can i get the quotation?

A:We will submit the quotation in 24 hours if getting detailed information during working days.

In order to quote for you earlier, please provide us the following information together with your inquiry:

1)3D Step of Files and 2D Drawings

2)Material requirement

3)Surface treatment

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as packing, labels, delivery, etc

Q: How you do the quality control?

A:1). Materials inspection by IQC;

2). During processing, our IPQC will check the injection molded parts every

3). hours, ensure no any rejects;

4).FQC will check the products before sending to the warehouses

5).100% inspected by QC before shipping out.

Q: What should we do if we receive defective products?

A: lf receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q: How to pack the moulds and products?

Q: How can i get the quotation?

A:We will submit the quotation in 24 hours if getting detailed information during working days.

In order to quote for you earlier, please provide us the following information together with your inquiry:

1)3D Step of Files and 2D Drawings

2)Material requirement

3)Surface treatment

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as packing, labels, delivery, etc

Q: How you do the quality control?

A:1). Materials inspection by IQC;

2). During processing, our IPQC will check the injection molded parts every

3). hours, ensure no any rejects;

4).FQC will check the products before sending to the warehouses

5).100% inspected by QC before shipping out.

Q: What should we do if we receive defective products?

A: lf receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q: How to pack the moulds and products?

A:1). For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer's request to pack.

Hot Searches