- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1500 KG

-

Capacity:

-

0.2-1.8 t/h

-

Keywords:

-

Lab Ball mill

-

Installation:

-

Engineer's Guide

-

Output size:

-

0.075-0.4mm

-

Feeding size:

-

0-25mm

-

Application:

-

Ore Grinding

-

The Machines classification:

-

Ball Mill Grinding Equipment

Quick Details

-

Capacity(t/h):

-

0.2-1.8 t/h

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

Refer to different models

-

Weight:

-

1500 KG

-

Capacity:

-

0.2-1.8 t/h

-

Keywords:

-

Lab Ball mill

-

Installation:

-

Engineer's Guide

-

Output size:

-

0.075-0.4mm

-

Feeding size:

-

0-25mm

-

Application:

-

Ore Grinding

-

The Machines classification:

-

Ball Mill Grinding Equipment

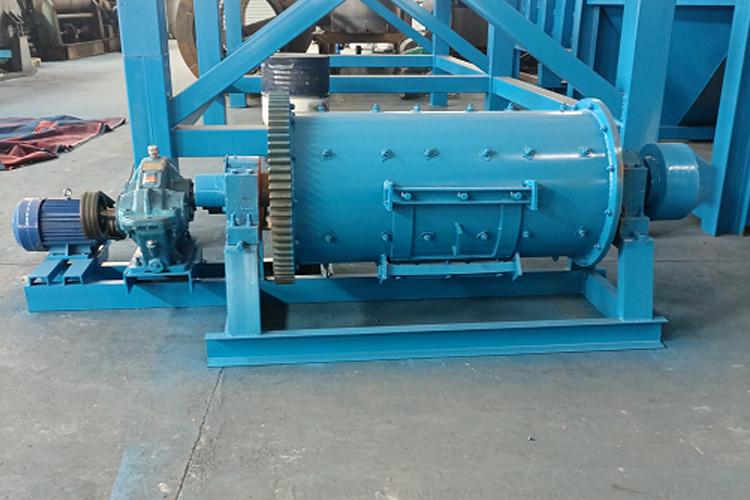

Product Overview

Ball Mill is widely used for the dry or wet grinding of all kinds of ores and other grindable materials in the production

industries of kaolin, quartz, feldspar, cement, silicate product, new building material, refractory, fertilizer, ferrous

metal,non-ferrous metals and glass ceramic industry. etc.

industries of kaolin, quartz, feldspar, cement, silicate product, new building material, refractory, fertilizer, ferrous

metal,non-ferrous metals and glass ceramic industry. etc.

Ball mill is the key equipment for smash the materials after they are primarily crushed. Ball Mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. Ball mill is an efficient tool for grinding many materials into fine powder, such as building material, chemical industry etc. There are two ways of grinding: the dry process and the wet process. It can be divided into tabular type and flowing type according to different forms of discharging material.

Product Parameters

|

Model

|

Volume

|

Speed

r/min

|

Feed size

mm

|

Capacity

kg/h

|

Balls loading

kg

|

Motor

kw

|

|

LZMQ600/800

|

150 L

|

48

|

2-25

|

60-200

|

100

|

4

|

|

LZMQ800/1000

|

200 L

|

43

|

2-25

|

100-400

|

150

|

7.5

|

|

LZMQ900/1200

|

400 L

|

45

|

2-25

|

150-600

|

200

|

11

|

Hot Searches